Graphene heat generating film for electric heating picture, and preparation method thereof

A technology of graphene heating film and electrothermal painting, applied in the field of manufacturing structure of new graphene heating body material, can solve the problems of poor reliability, hidden danger, small square resistance, etc., to improve realization and strength maintenance, and improve emission efficiency , the effect of improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of graphene hybrid film

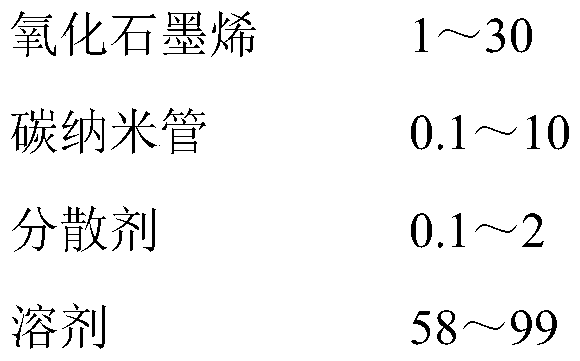

[0054] 1. Prepare raw materials according to the following weight (×100g)

[0055]

[0056] Wherein, dispersant is sodium dodecyl sulfate (SDS); Solvent is water;

[0057] 2. Preparation of heating element slurry

[0058] Add graphene oxide powder, single-wall carbon nanotubes, and dispersant to the solvent, stir and mix evenly, and prepare a heating element slurry. The viscosity of the heating element slurry is 5000cPs (usually 500~20000cPs, preferably 2000~8000cPs );

[0059] 3. Preparation of graphene-carbon nanotube composite film

[0060] Pass the heating element slurry through a roll coater for wet coating, and coat the heating element slurry on the substrate PET release film, wherein the coating thickness is controlled to be 100 μm (usually 10 to 1000 μm, preferably 50-200 μm); then the coated film is dried in a tunnel-type drying oven, and the heating element slurry is cured on the surface of the substrate to obtai...

Embodiment 1A

[0088] 1. Preparation of graphene hybrid film

[0089] Same as Example 1

[0090] 2. Preparation of graphene heating element

[0091] 1. Preparation of graphene hybrid composite film

[0092] Same as Example 1

[0093] 2. Patterning

[0094] Same as Example 1

[0095] 3. The first heat treatment

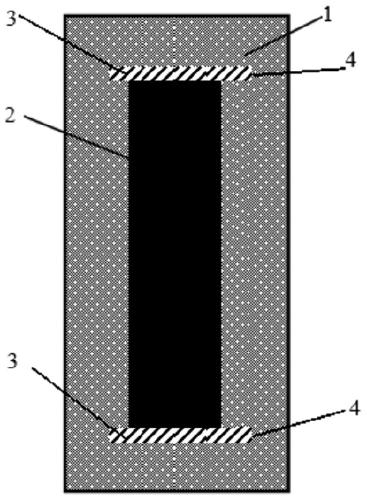

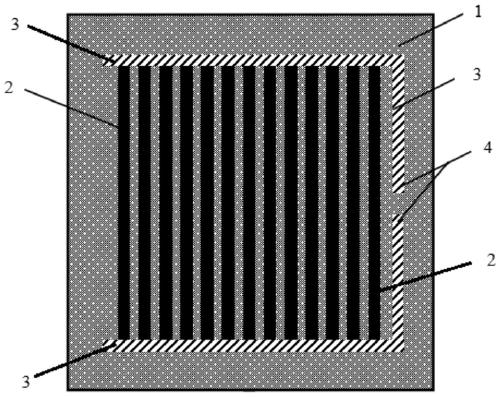

[0096] In addition to bonding multiple (13, usually ≥ 3, preferably 5-15) patterned graphene composite films on the surface of the heating element substrate epoxy resin plate, and the patterned graphene composite films are parallel to each other , at a distance of 5mm from each other (usually patterned graphene composite film 2-10mm), forming a patterned graphene composite film group, such as Figure 1A , all the other are identical with embodiment 1.

[0097] 4. Printed current-carrying electrode treatment

[0098] In addition to printing silver paste at both ends of the patterned graphene composite film group composed of a plurality of parallel patterned graphene composite ...

Embodiment 2

[0102] 1. Preparation of graphene hybrid film

[0103] 1. Prepare raw materials according to the following weight (×100g)

[0104]

[0105] Wherein, the dispersant is polyvinyl alcohol (PVA); the solvent is N-methylpyrrolidone (NMP);

[0106] 2. Preparation of heating element slurry

[0107] Except that the viscosity of the prepared heating element slurry is 8000cPs (usually 500-20000cPs, preferably 2000-8000cPs), the rest is the same as in Example 1;

[0108] 3. Preparation of graphene-carbon nanotube composite film

[0109] In addition to coating the heating element slurry on the PET release film; the coating thickness is 200 μm (usually 10-1000 μm, preferably 50-200 μm); the drying temperature is 180°C (usually 90-180°C); drying The time is except that 20min (usually 20~30min), all the other are identical with embodiment 1;

[0110] 4. Thermal reduction treatment

[0111] Except that the thermal reduction temperature is 600°C (usually 500-1000°C); the heating rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap