Railcar truck bolster

A technology for rail cars and bogies, which is applied in the direction of the bogie, the device for lateral relative movement between the underframe and the bogie, the parts of the railway car body, etc., which can solve the problems of difficulty in attaching wear-resistant plates and difficult assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

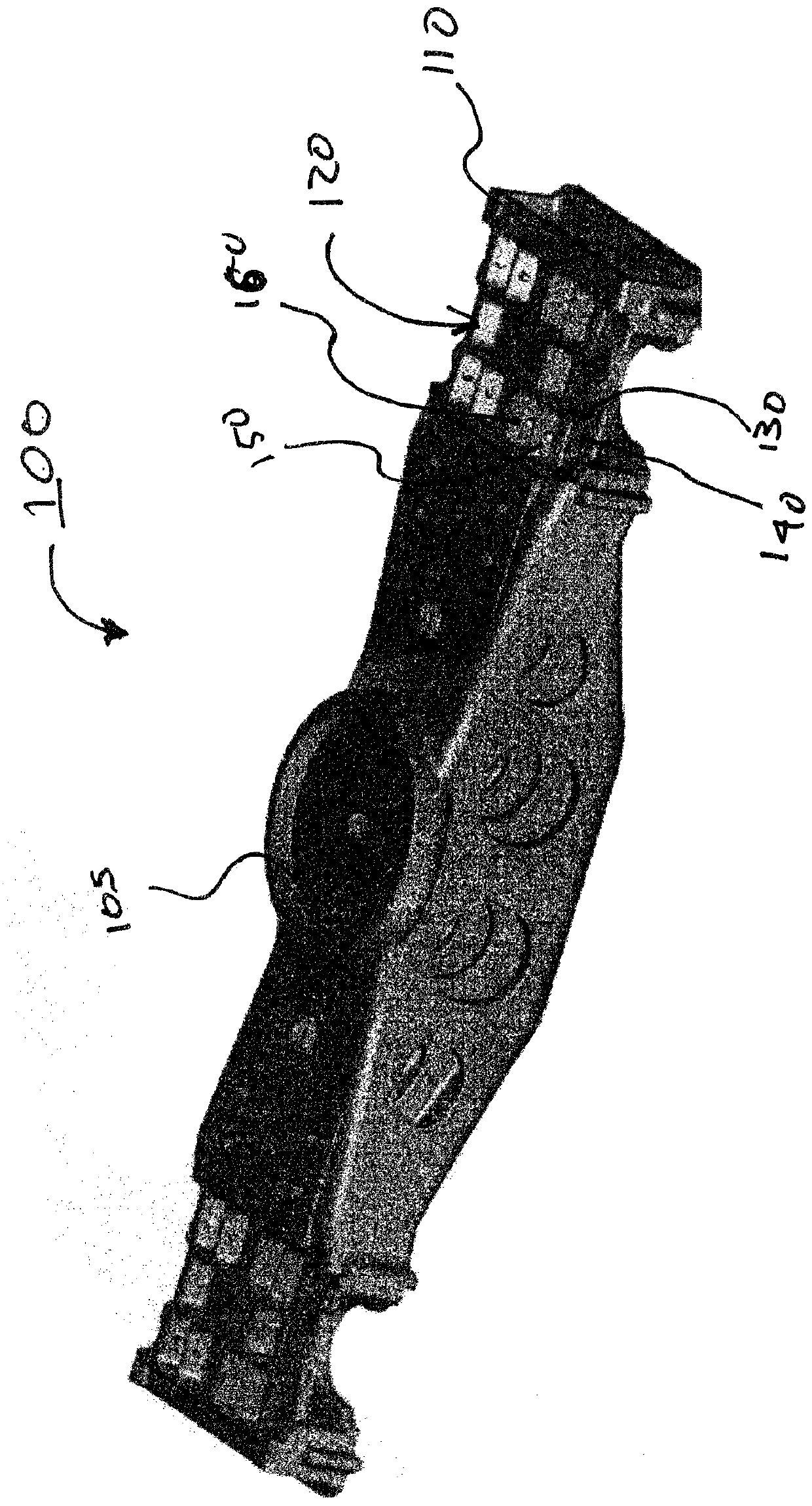

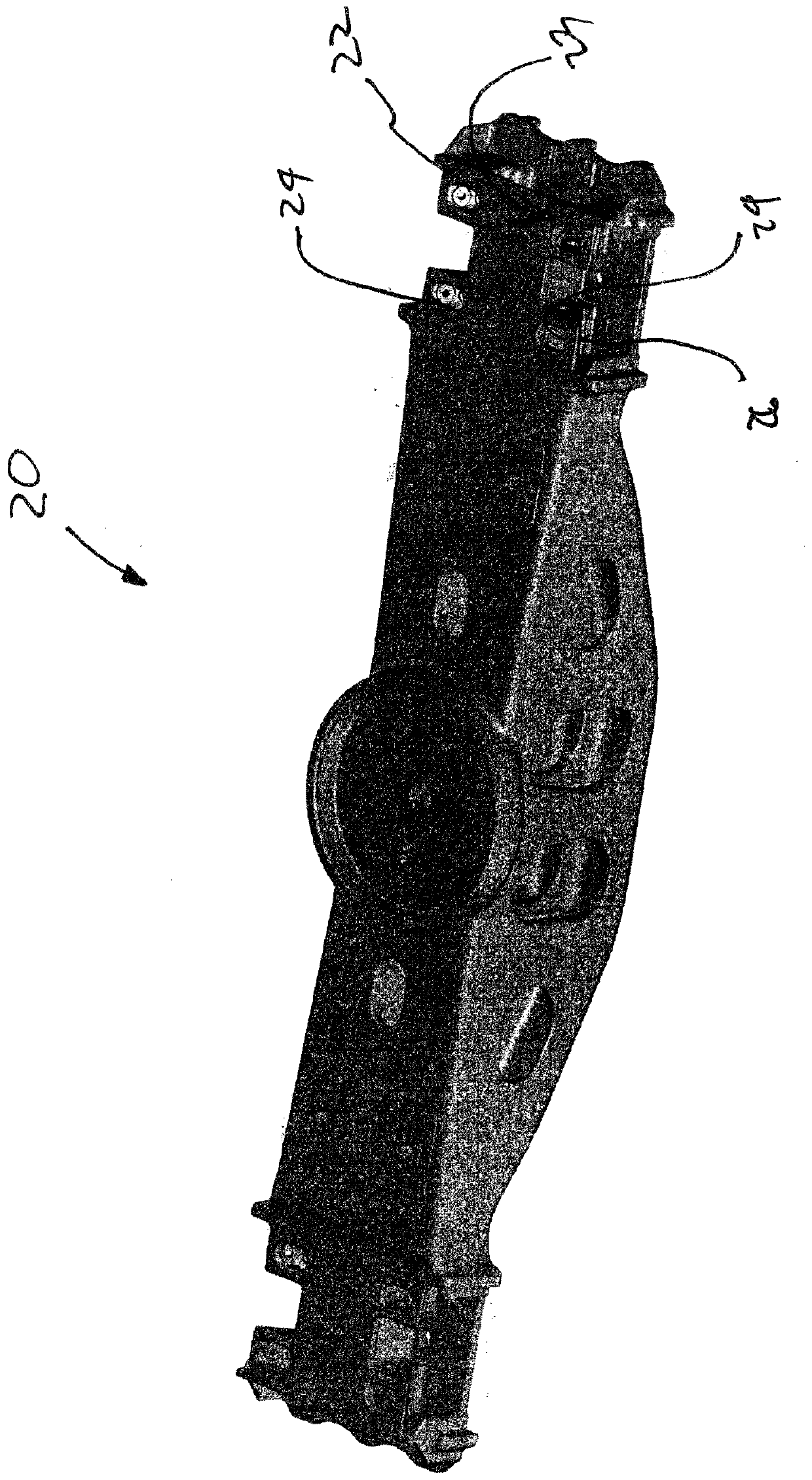

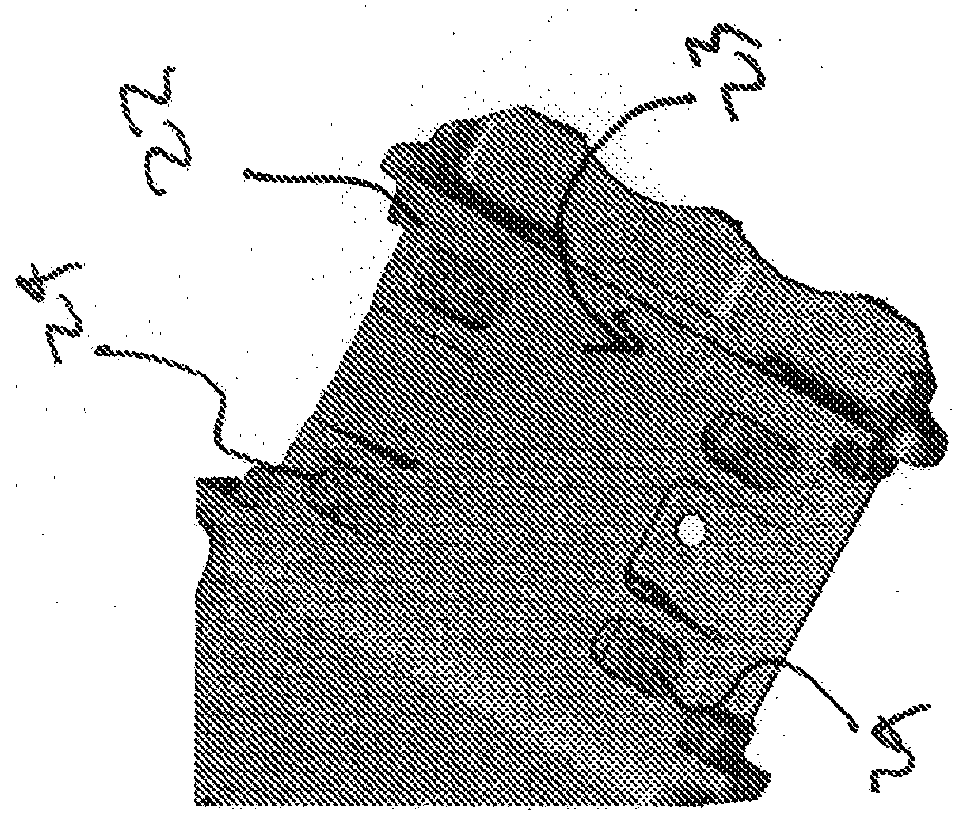

[0016] The present application describes an embodiment for attaching a wear plate to a wear surface of a railcar truck bolster. In particular, this application describes a bolster wear plate attachment surface that allows the use of multiple bolts of different lengths to bolt the wear plates. A shorter bolt extends through the upper hole of the wear plate and the surface of the wear plate and through the first recess in the upper surface of the bolster. A second, longer bolt extends through the lower hole and wear plate surface and through a second recess in the upper surface of the bolster. Both the first recess and the second recess are located at substantially the same height and allow fastening of the bolt with a corresponding nut or other connection of similar form. That is, because the lower bolt is connected in a second recess separate from the first recess, the corresponding connector can be tightened without having to pass through the small opening in the upper bolst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com