fan blade

A technology of fan blades and blades, which is applied in the field of wind power generation, can solve the problems of unfavorable fan blades running for a long time, the accumulation of stress damage at the connection end, etc., and achieve the effects of reducing the accumulation of stress damage, increasing the service life, and reducing the force difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below by means of specific examples, but the present invention is not limited to the scope of the following examples.

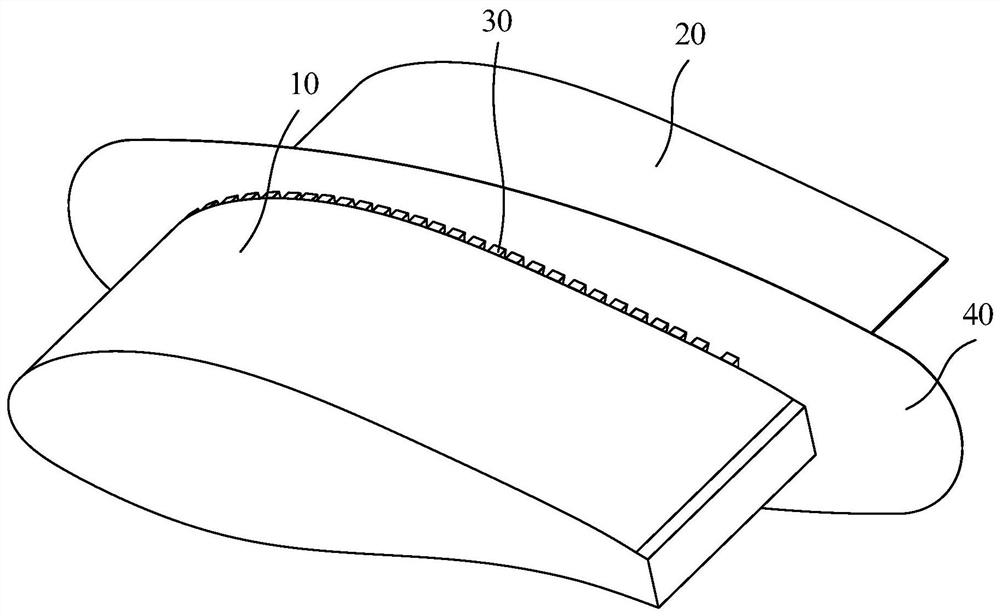

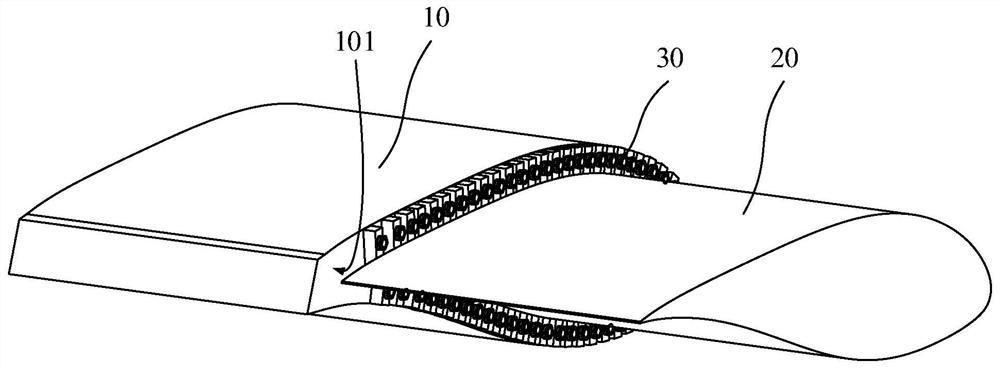

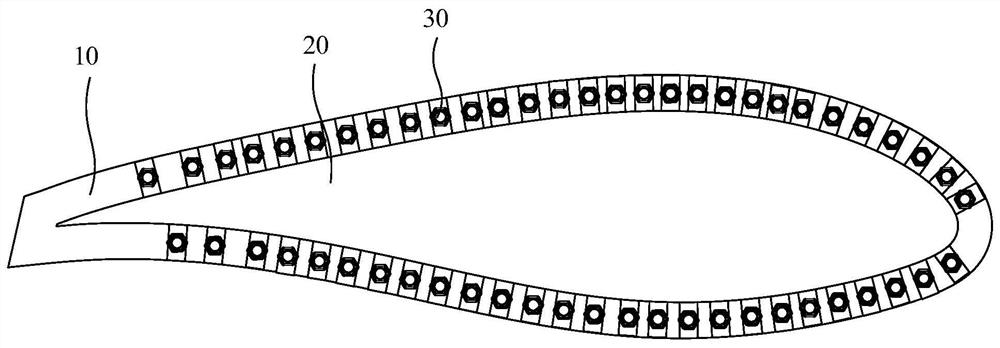

[0054] like Figure 1-4 As shown, it is a fan blade of this embodiment, and the fan blade includes a first blade section 10 and a second blade section 20, the first blade section 10 is arranged closer to the blade root of the fan blade relative to the second blade section 20, and the second blade section 20 is arranged closer to the blade root of the fan blade. The first blade section 10 and the second blade section 20 have oppositely arranged first connecting surface 101 and second connecting surface 201 respectively, and the chord length of the blade airfoil section at the second connecting surface 201 is smaller than that at the first connecting surface 101. The chord length of the section. Wherein, the blade airfoil section refers to the cross section of the blade perpendicular to the leading edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com