Flow regulating valve

A flow control valve and flow rate technology, which is applied in the field of flow control valves for regulating refrigerant flow, can solve problems such as easy occurrence and growth, refrigerant peeling, pressure changes, etc., to achieve smooth flow, small pressure loss, and suppress pressure changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings.

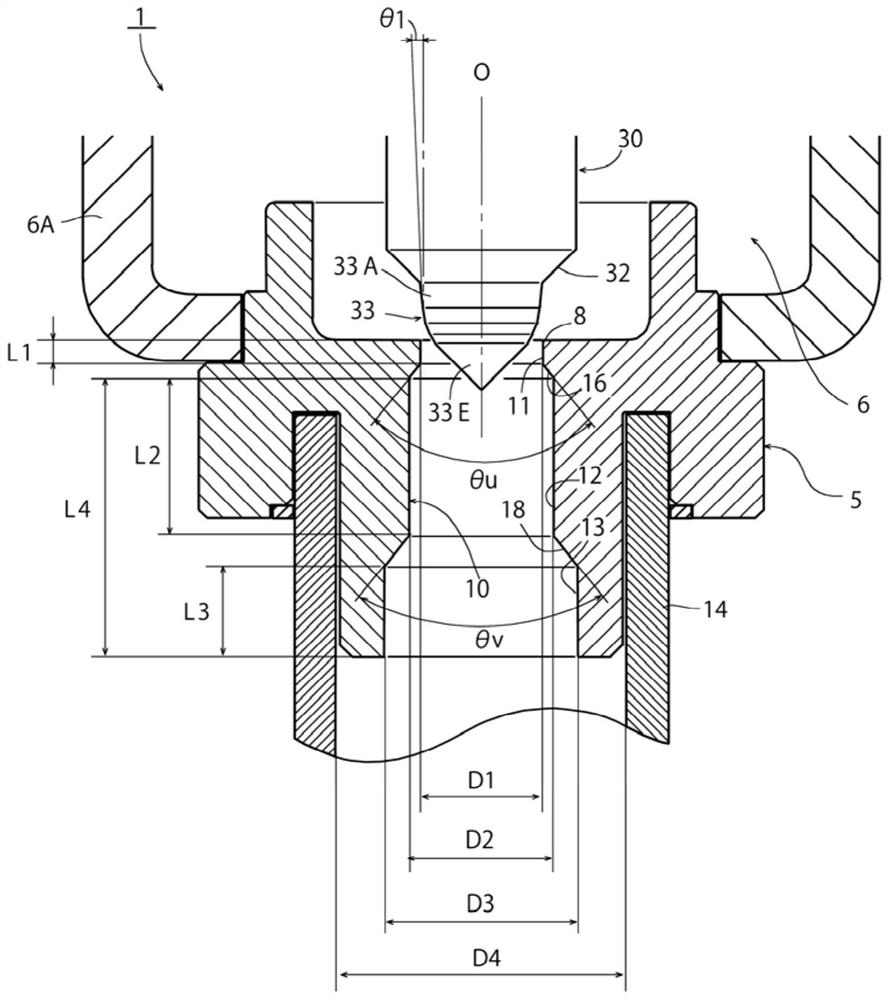

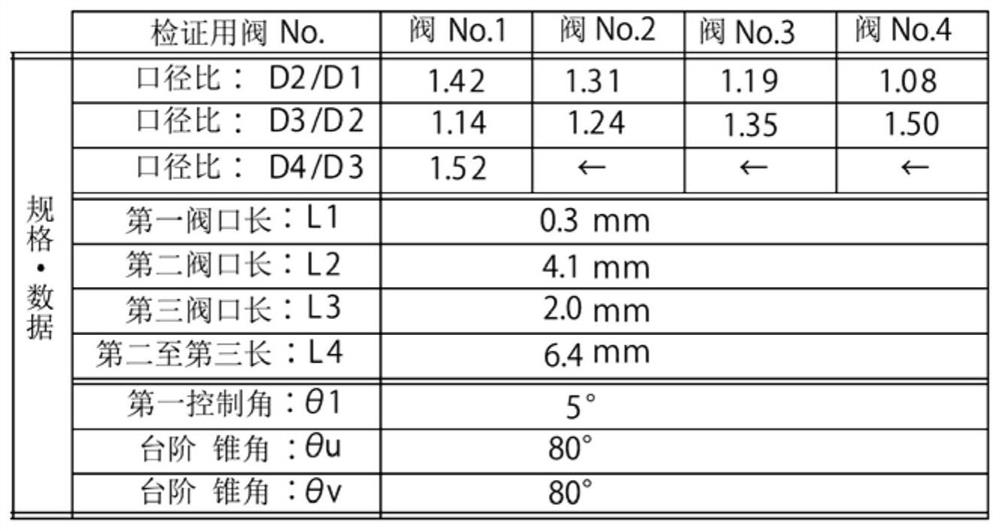

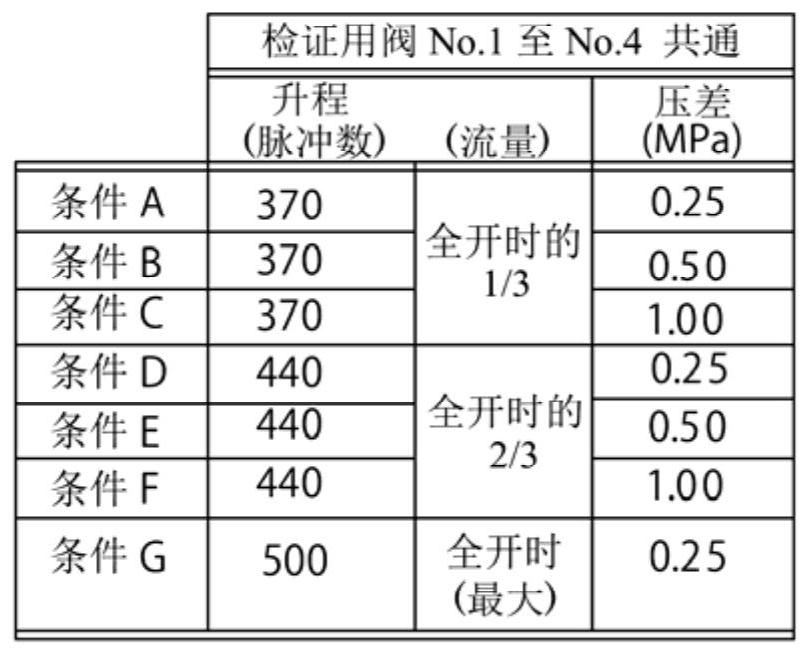

[0040] figure 1 It is a cross-sectional view showing an essential part of an embodiment of the flow control valve according to the present invention. In addition, in figure 1 , for the above Figure 6A , Figure 6B The parts corresponding to the respective parts of the shown conventional flow regulating valve 1" are given the same reference numerals.

[0041] The flow regulating valve 1 of the illustrated embodiment is the same as the above-mentioned Figure 6A , Figure 6B The conventional flow control valve 1" shown is similarly formed in such a manner as to obtain characteristics similar to the equal percentage characteristic, and includes: a valve main body 5 to which a valve chamber forming member 6A is fixed, and is provided as the main body. The valve port 10 (described later in detail) of the characteristic part of the invention; and the valve cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com