Windshield wiper device

A wiper and wiper arm technology, which is used in transportation and packaging, vehicle cleaning, vehicle maintenance, etc., can solve the problems of difficult sensor wiring processing, unclear sensor installation direction, etc., and achieve the effect of suppressing chatter vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

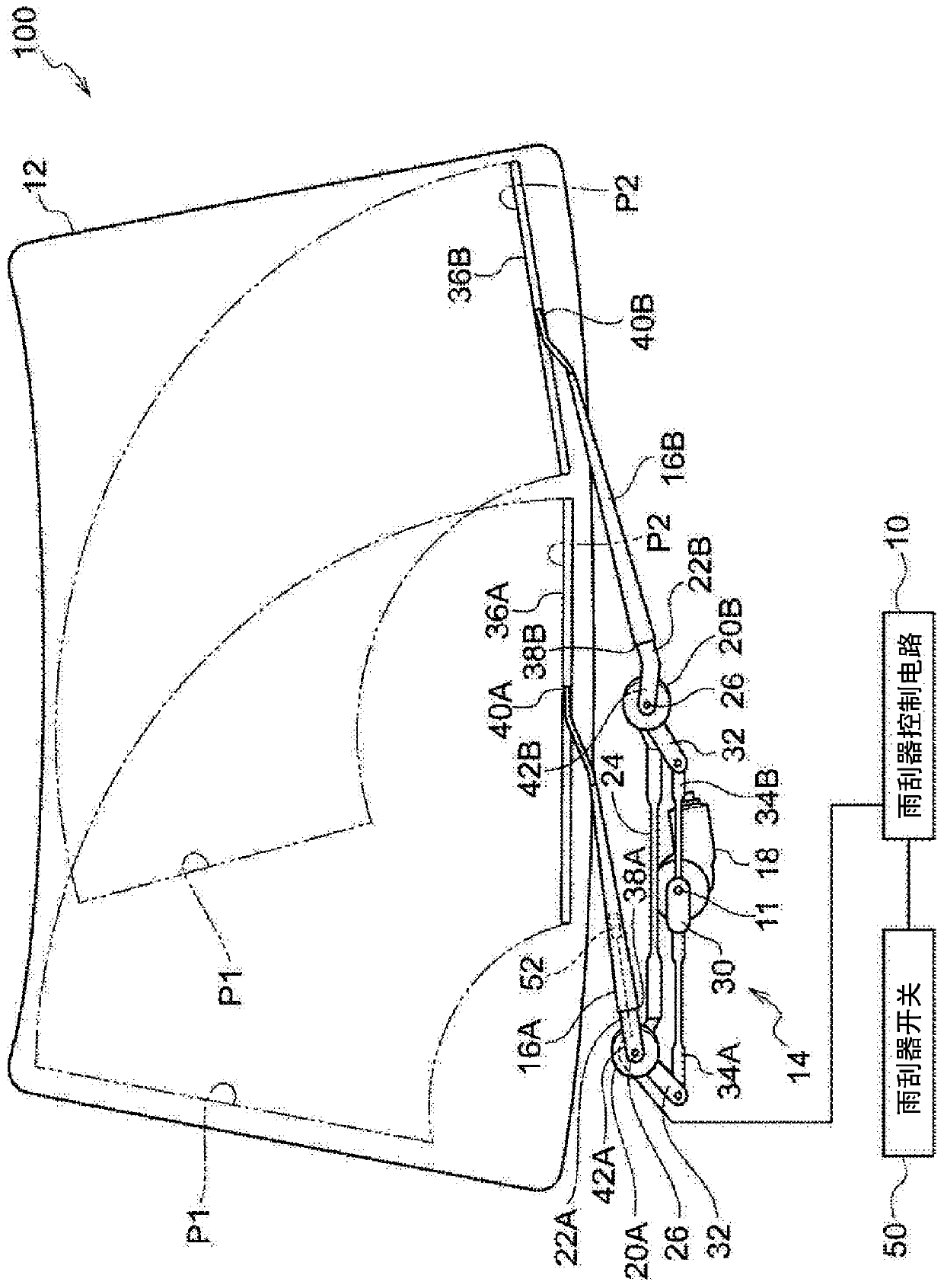

[0041] figure 1 It is a schematic diagram showing the structure of the wiper device 100 according to the embodiment of the present invention. The wiper device 100 is used to wipe the windshield 12 included in a vehicle such as a passenger car with the wiper blades 36A, 36B.

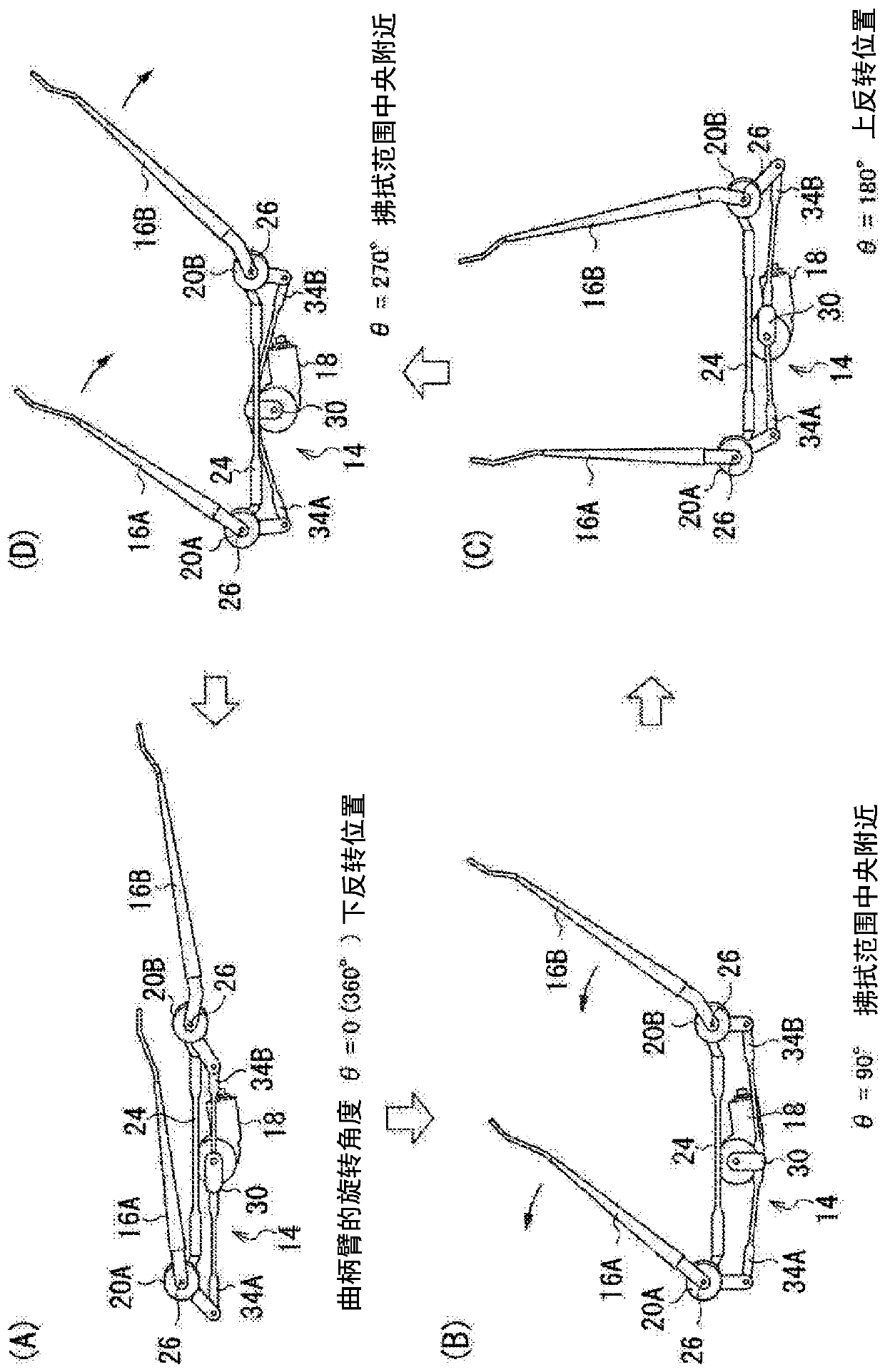

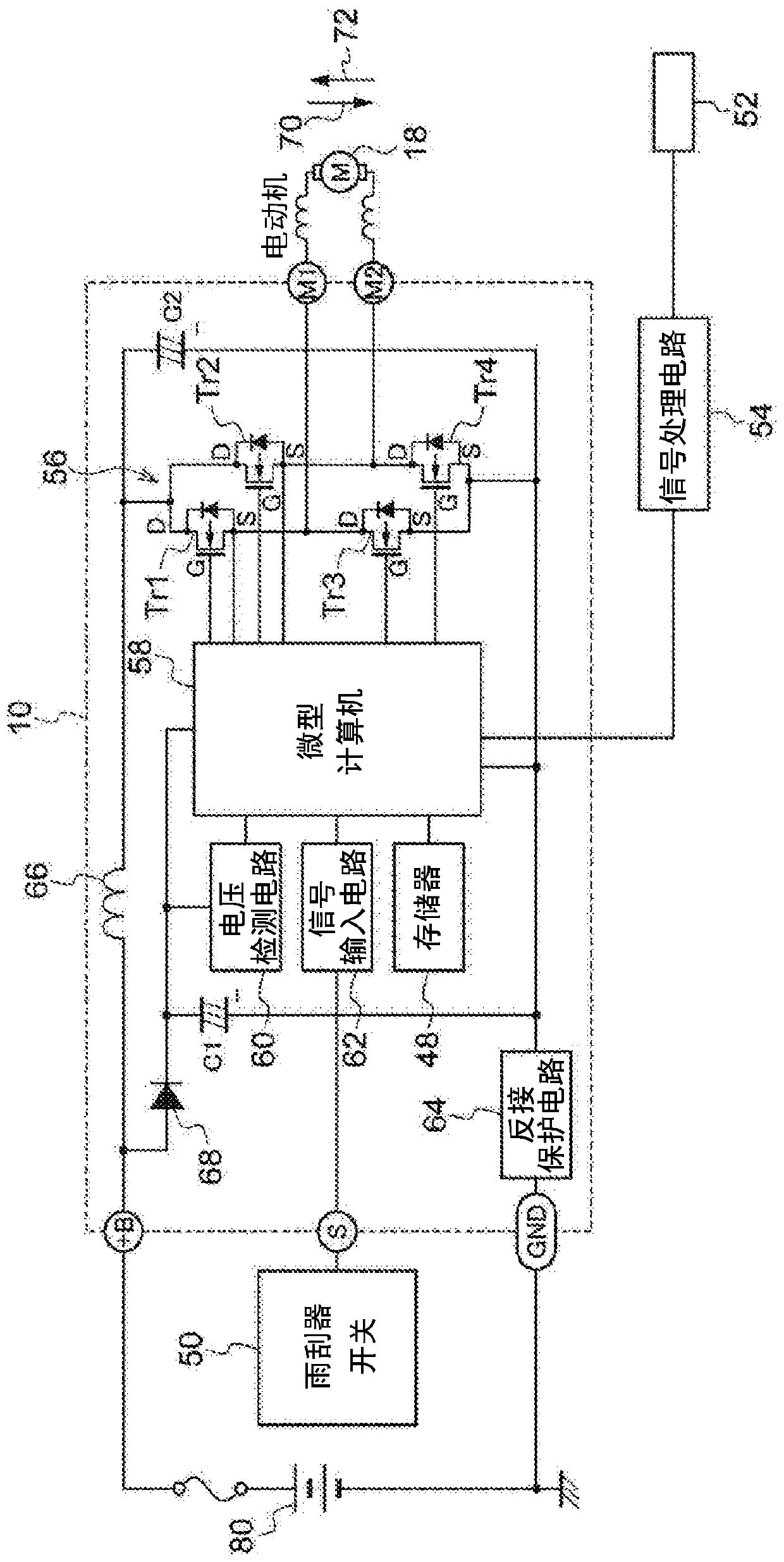

[0042]As shown in this figure, the wiper device 100 includes: a wiper motor 18, which drives an unillustrated rotating shaft to rotate, and drives the output shaft 11 to rotate through an unillustrated reduction mechanism composed of a worm gear and the like; a link mechanism 14, whose Converts rotational drive of the output shaft 11 into reciprocating movement of two links 34A, 34B described later; and two wiper arms 16A, 16B at the rotating shaft 26 that rotates in conjunction with the reciprocating movement of the links 34A, 34B The bases 42A, 42B are connected to swing by the rotation of the rotating shaft 26, so that the wiper blades 36A, 36B respectively connected to the front ends 40A, 40B are pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com