Fluid control valve

A fluid control valve and cylinder technology, which is applied to fluid pressure actuating devices, multi-port valves, valve devices, etc., can solve the problem of increasing the opening speed of the lift-lock poppet valve 9, and achieve suppression of pressure loss and impact. sound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

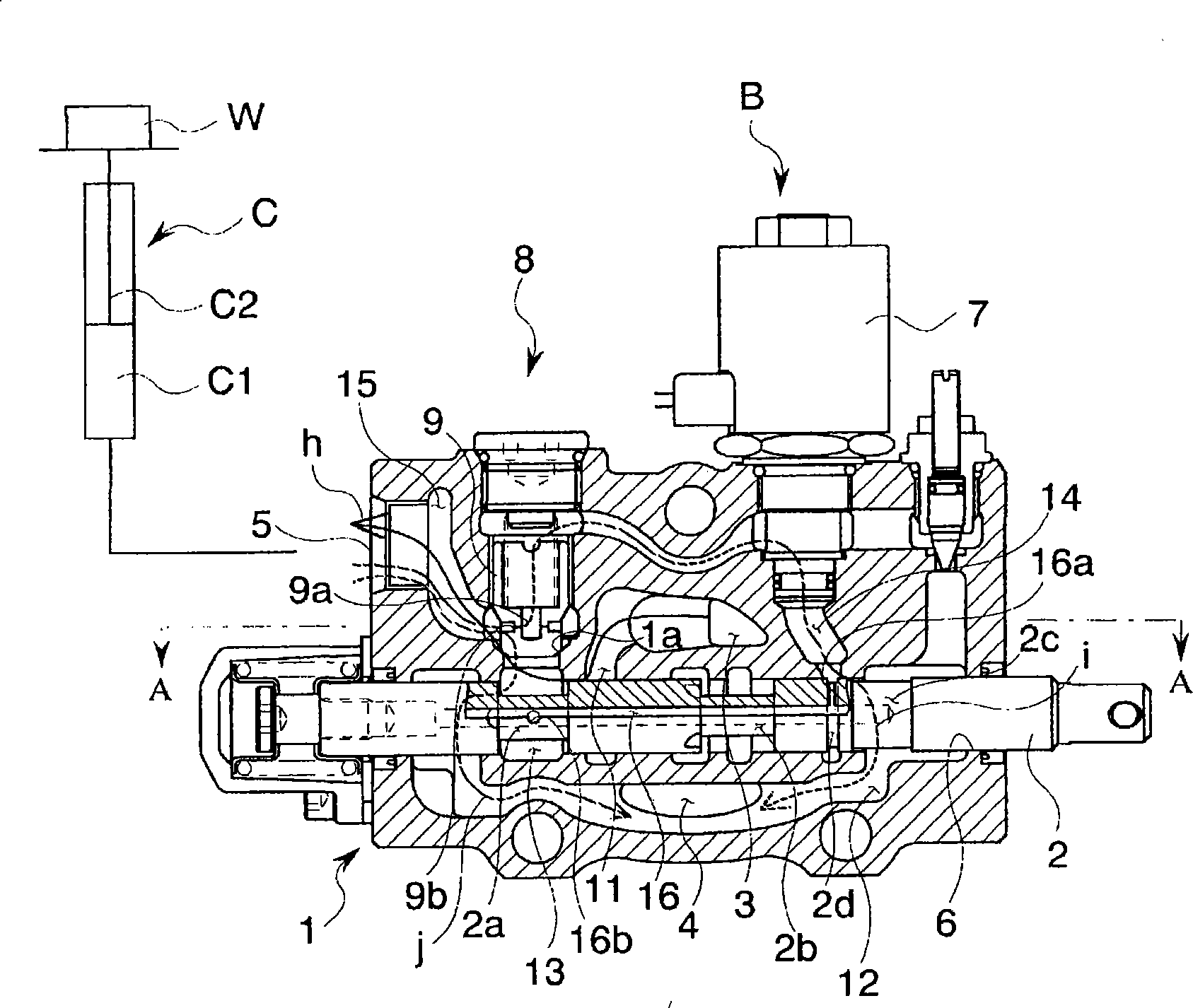

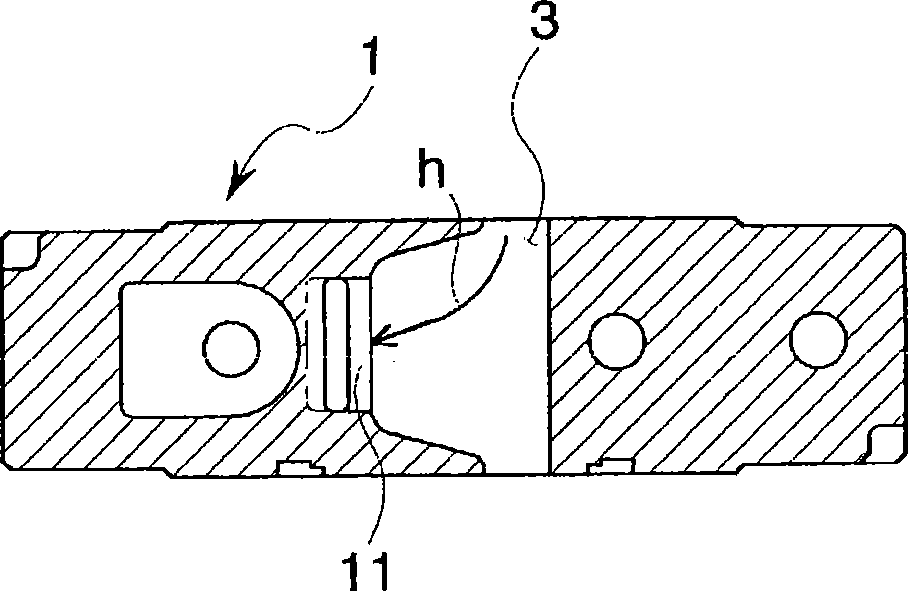

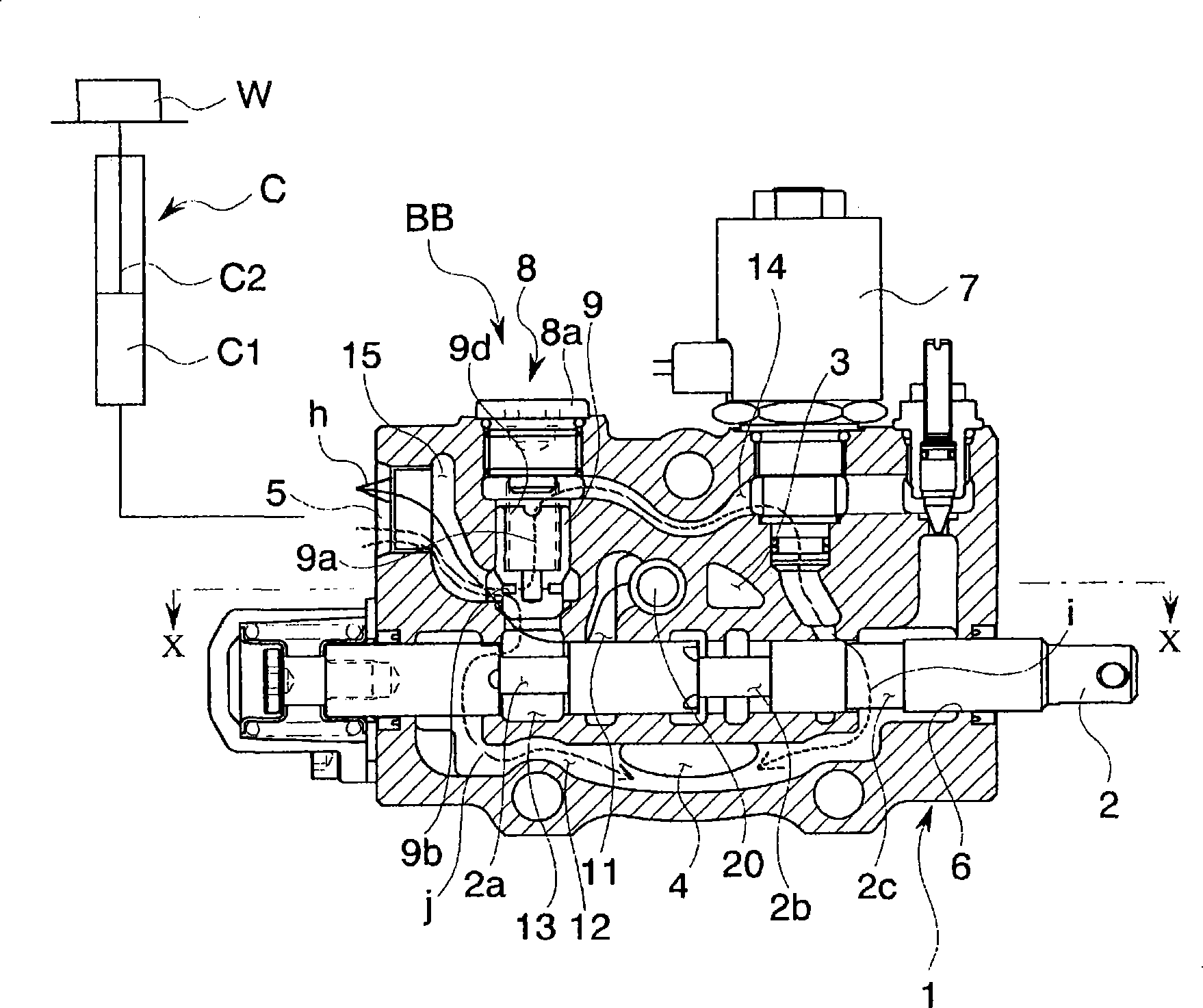

[0062] Below, refer to figure 1 and figure 2 Preferred embodiments of the present invention will be described. Here, the same names and symbols are used for parts corresponding to the above-mentioned conventional fluid control valves.

[0063] The fluid control valve B of this embodiment is mounted on a forklift, which has figure 1 A side sectional view showing, figure 2 Expressed figure 1 A-A sectional view of the structure.

[0064] Specifically, this fluid control valve B has substantially the same structure as the above-mentioned conventional fluid control valve BB. That is, the fluid control valve B includes a valve main body 1 and a valve stem 2 .

[0065] The valve main body 1 is equipped with: a sleeve 6, which is connected to the suction port 3 for sucking the working fluid, the discharge port 4 for discharging the working fluid, and the cylinder port 5 for outputting the working fluid to the lifting cylinder C; the solenoid valve 7, which is opened closin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com