A general on-machine non-contact calibration method for milling cutter eccentricity parameters

A calibration method, non-contact technology, applied in metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the limitations of analysis methods and means, difficult quantitative evaluation of tool eccentric state, unfavorable high-precision CNC milling processing and other problems, to achieve the effect of convenient operation of the instrument, high measurement accuracy, and elimination of cutting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0149] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0150] A universal on-machine non-contact calibration method for milling cutter eccentricity parameters, comprising the following steps:

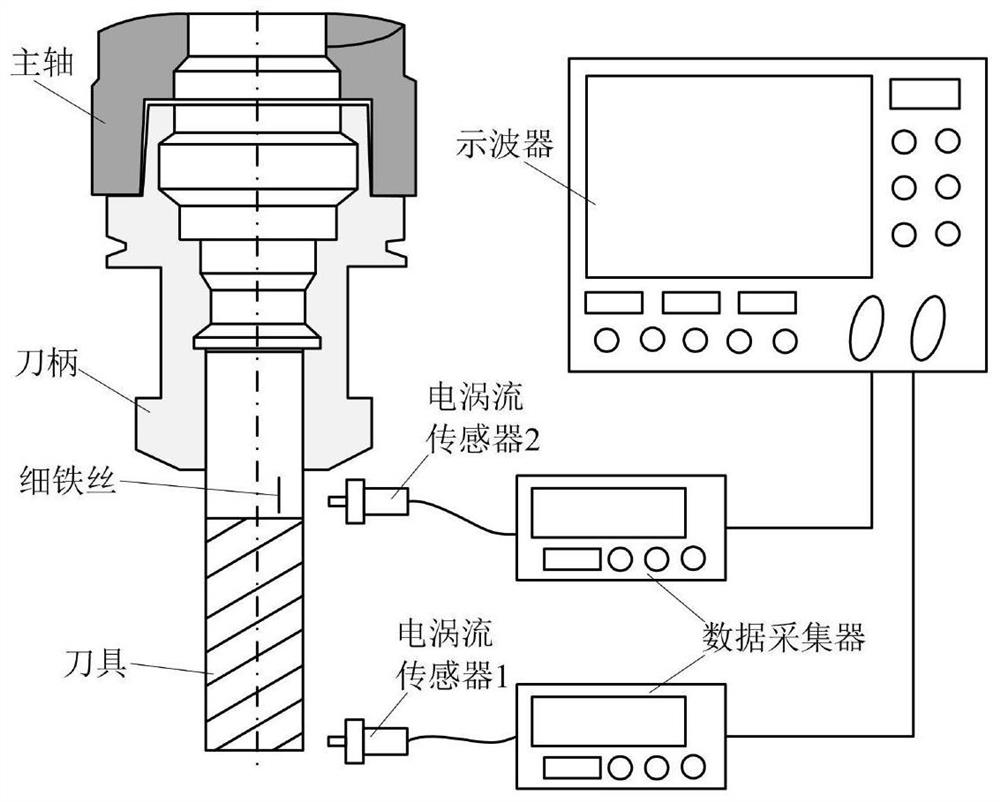

[0151] Step 1) Refer to figure 1 , set up an on-machine non-contact measurement system for milling cutter eccentricity parameters, and make preparations before the calibration test;

[0152] 1.1) Tool installation:

[0153] Prepare the tool that needs to be calibrated with eccentric parameters, and prepare a thin iron wire (diameter ≤ 0.05mm, length about 5mm), use adhesive tape to wrap the thin iron wire on the tool holder; connect the tool with the handle, and connect the handle Installed on the spindle of the machine tool to ensure the normal operation of the spindle;

[0154] 1.2) Measuring instrument installation:

[0155] Prepare the eddy current non-contact measurement system, including the eddy current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com