Anti-jamming material bin

A silo and valve plate technology, applied in the field of machinery, can solve the problems of gate valve plate stuck and unable to close, pollute the environment, material leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be further described in detail below.

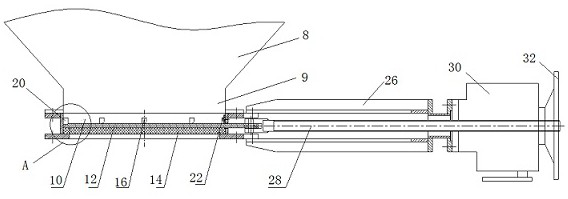

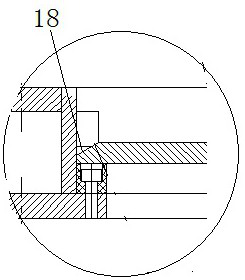

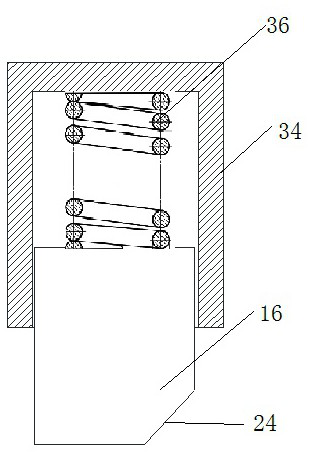

[0018] Such as Figure 1 to Figure 3 As shown, the present invention provides a jam-resistant bin. Wherein, the silo 8 includes an opening 9 located below it, and a valve body 10 , a horizontal plate-shaped valve plate 12 and a driving device are arranged below the opening of the silo 8 . The driving device drives the valve plate 12 to move horizontally back and forth to close or open the opening of the feed bin. The valve plate 12 includes a front end and a rear end. When it is closed, the forward direction is the front end, and the opposite direction is the rear end. The valve body 10 is a zigzag structure matching the shape of the opening of the silo, and consists of a front panel, a rear panel (not shown) and two side panels (not shown). The edge of the valve plate 12 slides on the two side plates, and the channel steel with the opening facing inward can be used as the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com