Recycling method of concrete waste material and recycled concrete

A technology of recycled concrete and concrete, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of waste of natural resources, high freight costs, secondary environmental pollution, etc., and achieve good stability and strength , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

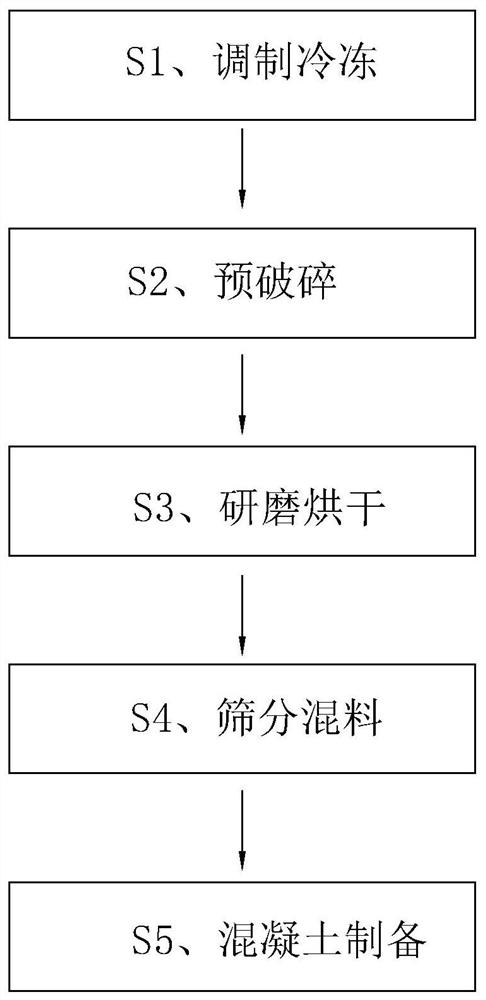

[0045] refer to figure 1 , a method for recycling concrete waste disclosed in the present application, comprising the following steps:

[0046] S1: Humidity adjustment and freezing; add water to the waste concrete material and waste ceramic material to adjust the humidity respectively. When adding water to adjust the humidity, control the water content to 10% of the total weight. After humidification, put the waste concrete material and waste ceramic material into the industrial freezer Carry out freezing and refrigeration, the freezing temperature is -20°C, and the freezing time is 75 minutes;

[0047] S2: Pre-crushing; use a crusher to crush the frozen waste concrete material and waste ceramic material separately, and control the particle size of the two to not exceed 40mm;

[0048] S3: Grinding and drying; put the frozen waste concrete material and waste ceramic material into a grinder for grinding, exhaust and dust on one side during grinding, and dry the ground waste con...

Embodiment 2-6

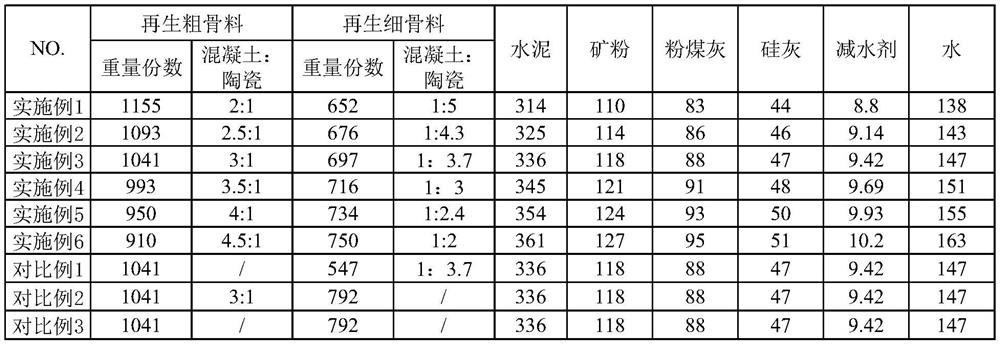

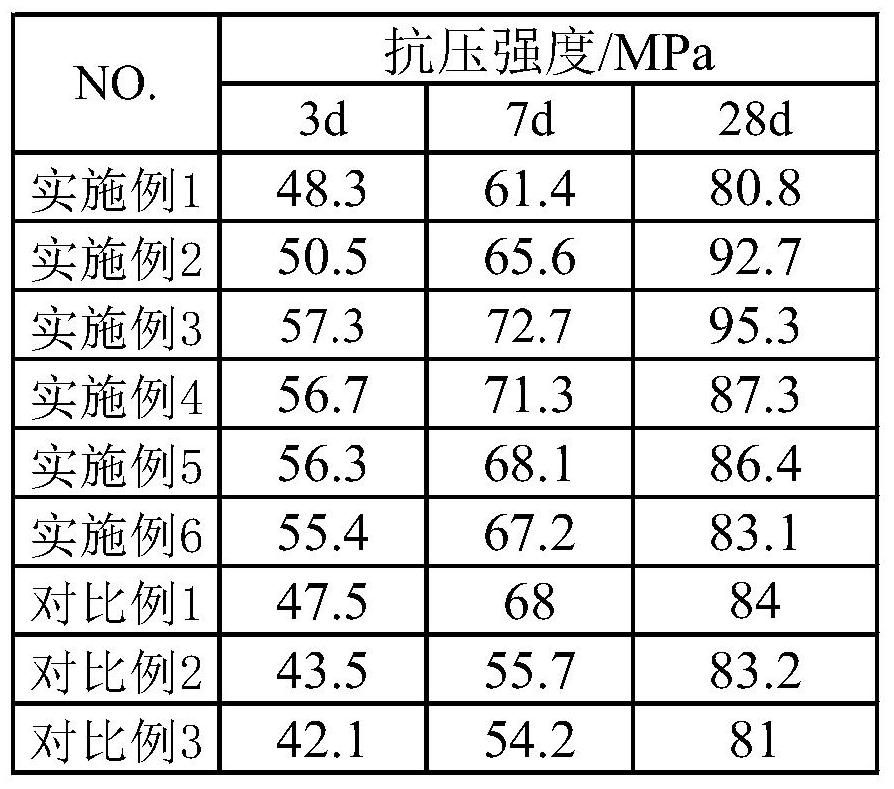

[0060] The difference from Example 1 is that the proportion of waste concrete material and waste ceramic material in the recycled coarse aggregate or recycled fine aggregate used to prepare recycled concrete is different, and the weight parts of each component in recycled concrete are different. The specific values are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com