Slope anchor cable weaving processing platform

A technology for processing platforms and anchor cables, which is applied in braids, textiles, papermaking, infrastructure engineering, etc., can solve problems such as steel strand rotation, safety accidents of surrounding workers, and hidden safety hazards, so as to achieve safety protection measures in place and reduce safety hazards. Hidden dangers, the effect of less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

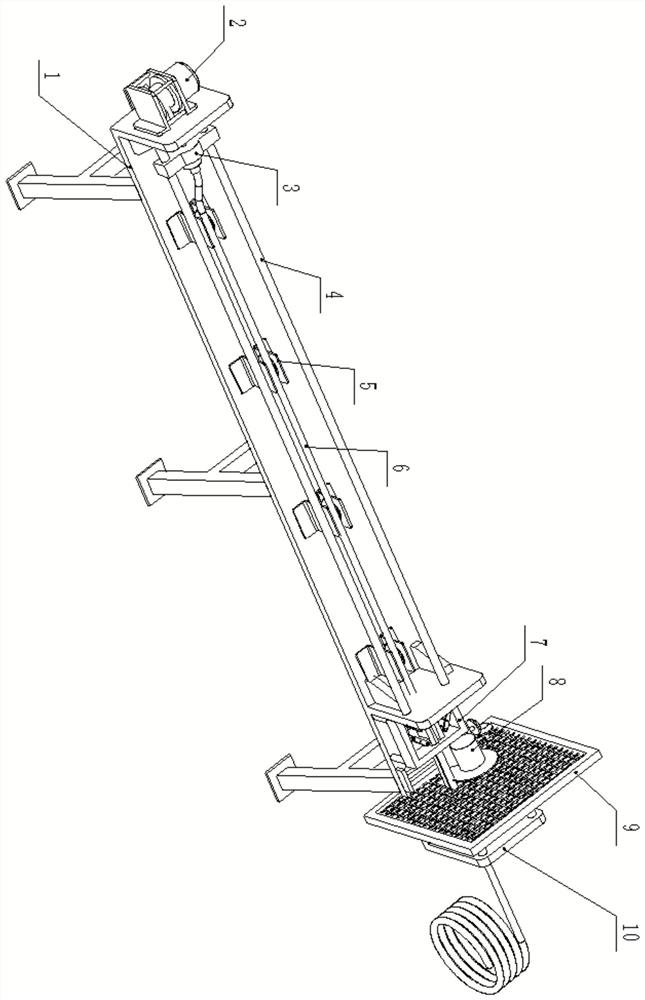

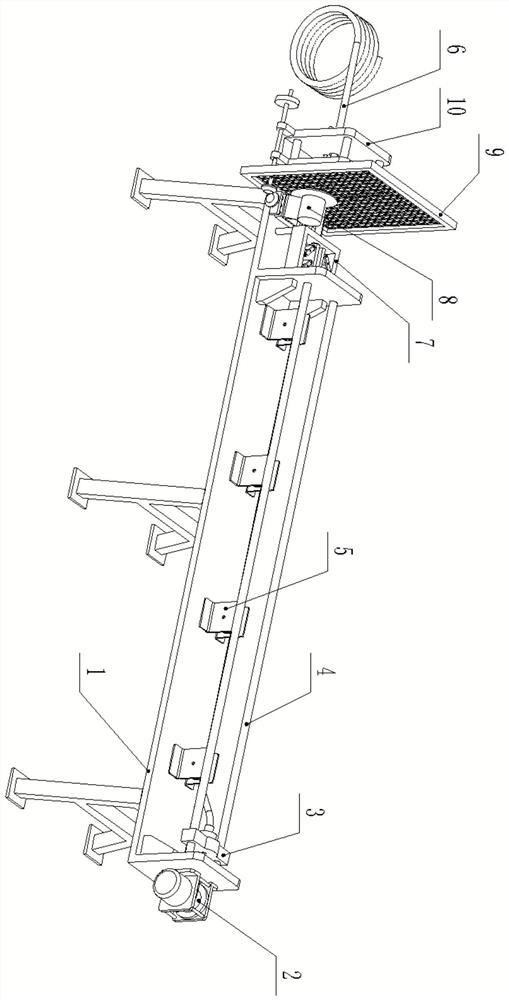

[0061] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0062] Aiming at the deficiency that there is no special platform for anchor cable loosening, cutting and weaving processing, the problem to be solved by the present invention is to manufacture a special platform for anchor cable weaving processing, so as to improve the positioning accuracy of each component of anchor cable processing and reduce the Reduce the labor intensity of workers, improve work efficiency and enhance operation safety.

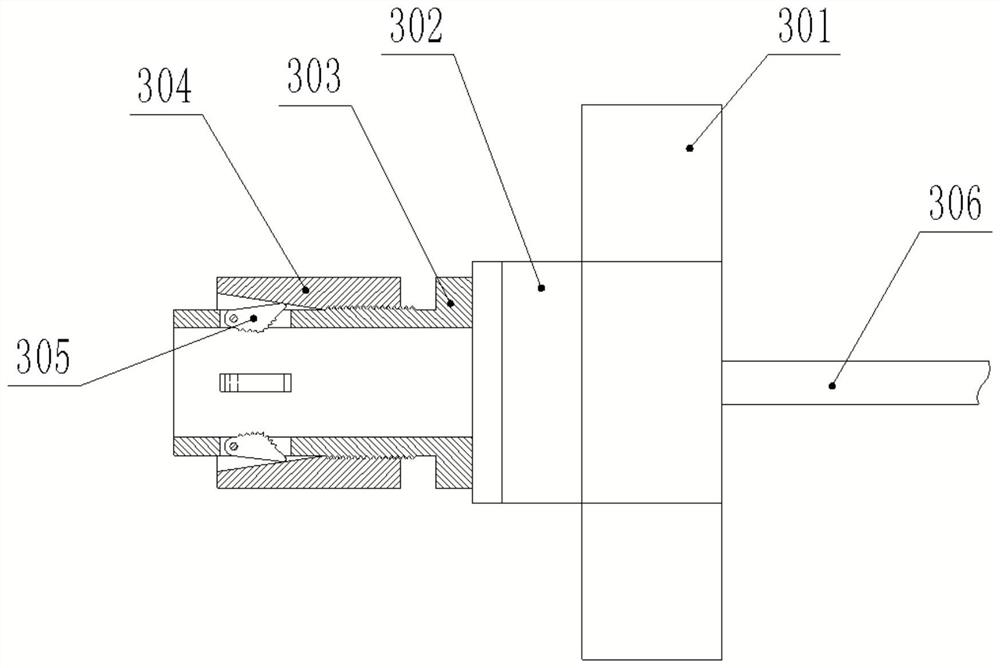

[0063] A slope anchor cable weaving processing platform, comprising: a support platform 1 for placing steel strands 6, and the steel strands 6 pass through the force limiting device 10 on the support platform 1, the cutting device 8, the cable clamping device 7, and the track 4 and the cable device 3; the cutting device 8 is used to cut off the steel strand 6, the clamping device 7 is used to clamp the steel strand 6 bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com