Heat collection type reactor with high heat utilization rate and working method of heat collection type reactor

A reactor and utilization rate technology, applied in the field of thermal collectors, can solve problems such as unfavorable light-to-heat conversion, and achieve the effects of increasing heat exchange area, large heat transfer coefficient, and high heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

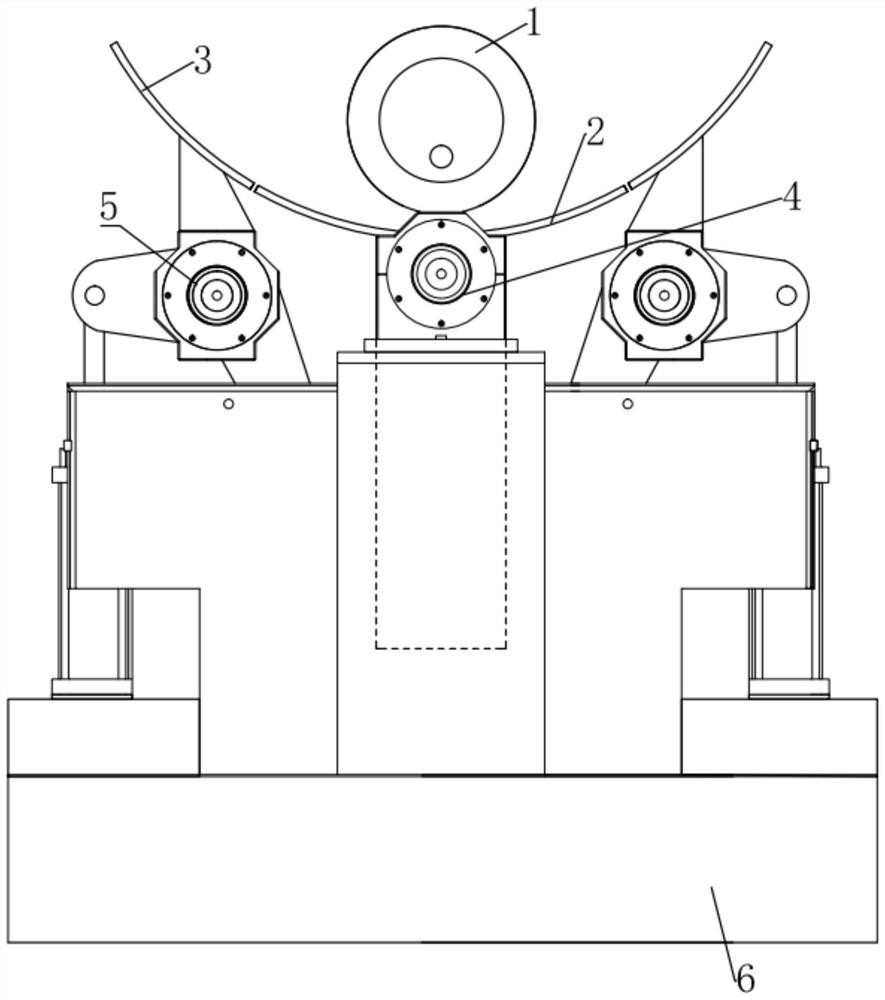

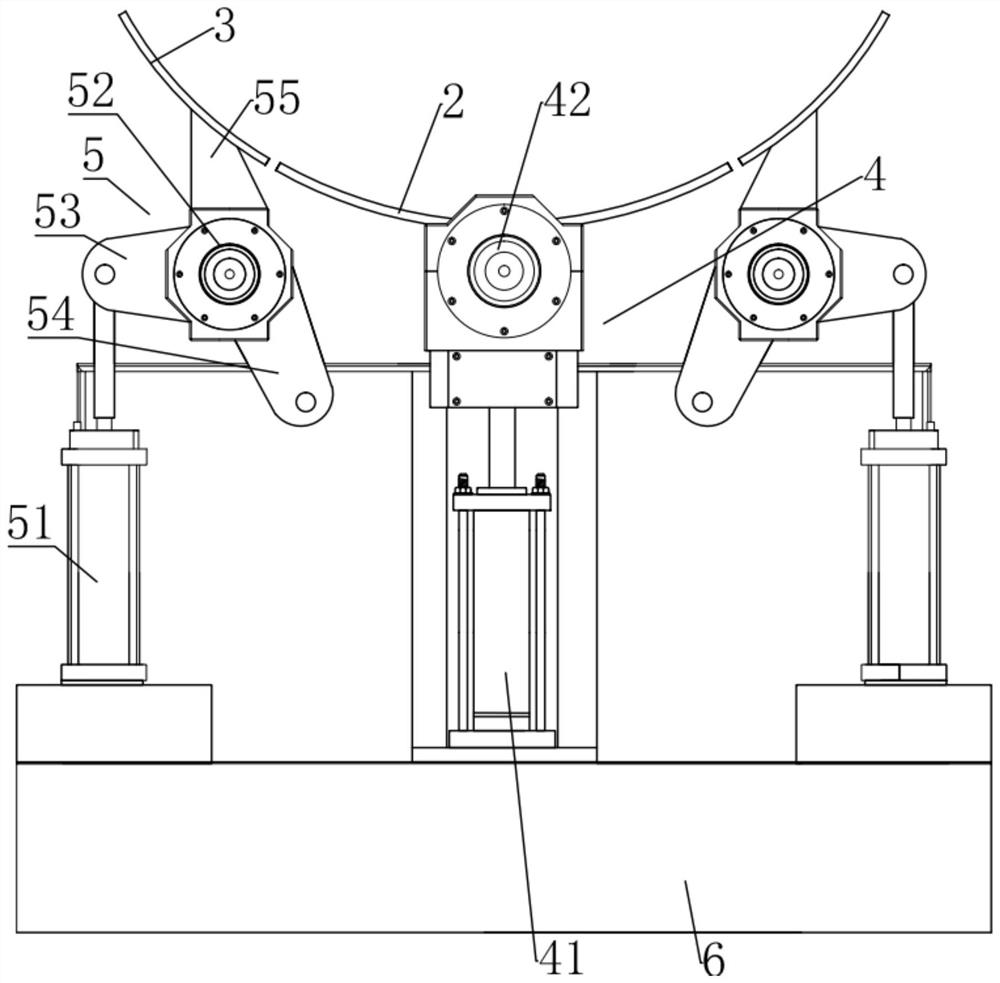

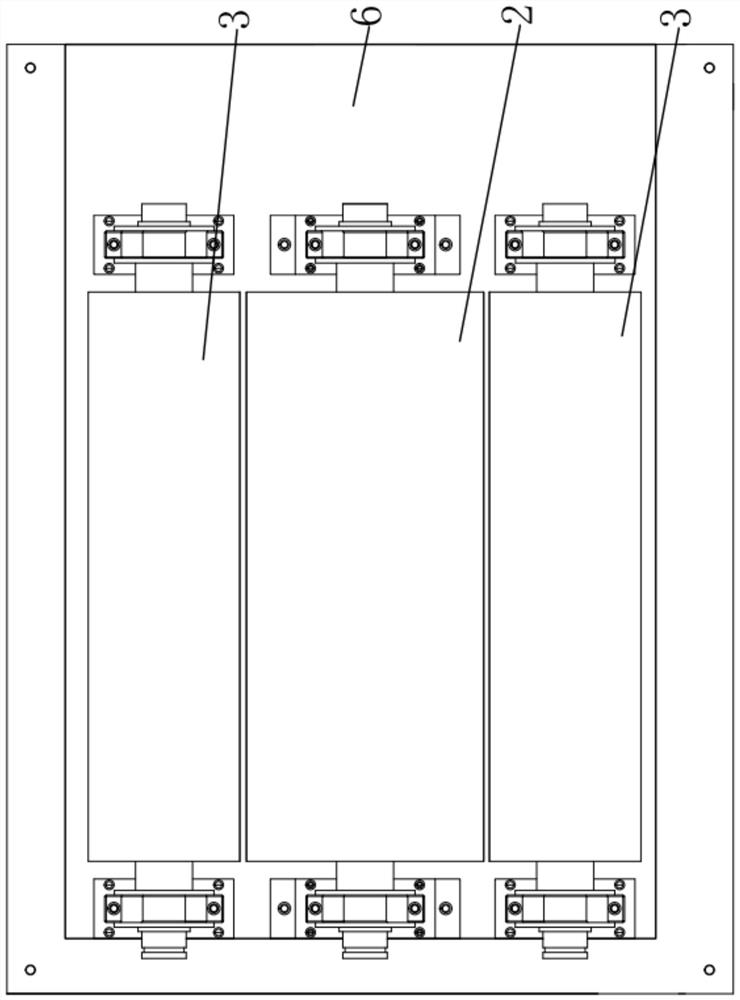

[0045] Such as Figure 1-6 The heat-collecting reactor with high heat utilization rate shown includes reactor 1, condenser mirror 1 2, two symmetrically arranged condenser mirrors 2 3, condenser mirror 1 height adjustment device 4, and two symmetrically arranged condenser mirrors 2 Angle adjustment device 5 and support platform 6, described concentrating mirror surface one height adjustment device 4, two concentrating mirror surface two angle adjustment devices 5 and reactor 1 that are arranged symmetrically are all arranged on the support platform 6, and described concentrating mirror surface one 2 is provided with On the converging mirror surface one height adjusting device 4, the concentrating mirror surface two 3 is arranged on the concentrating mirror surface two angle adjustment device 5, and the two concentrating mirror surfaces two 3 that are symmetrically arranged are respectively arranged on the both sides of the concentrating mirror surface one 2, and the Condensing...

Embodiment 2

[0049] Based on the structure of Embodiment 1, such as Figure 7 , 8 The shown reactor 1 includes a metal heat absorbing tube 10, a vacuum heat collecting tube 11, a glass tube 12, two symmetrically arranged adapters 13, two symmetrically arranged metal expansion joints 14, a high temperature molten salt 15, and a set of reaction Thin tube 16, two symmetrically arranged connecting plates 17, liquid inlet joint 18 and liquid outlet joint 19, the vacuum heat collecting tube 11 is set outside the glass tube 12, and the glass tube 12 is set on the metal heat absorbing The outside of the tube 10, and the two ends of the metal heat absorbing tube 10 along the axis protrude from the glass tube 12, the metal heat absorbing tube 10 and the glass tube 12 are coaxially arranged, and the two symmetrically arranged metal expansion tube joints 14 are respectively arranged at both ends of the glass tube 12, and the metal expansion joint 14 and the glass tube 12 are fixedly connected through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com