Intake flow nozzle assembly and intake flow measuring device

A technology of air intake flow and measuring device, which is applied in the direction of measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., to achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

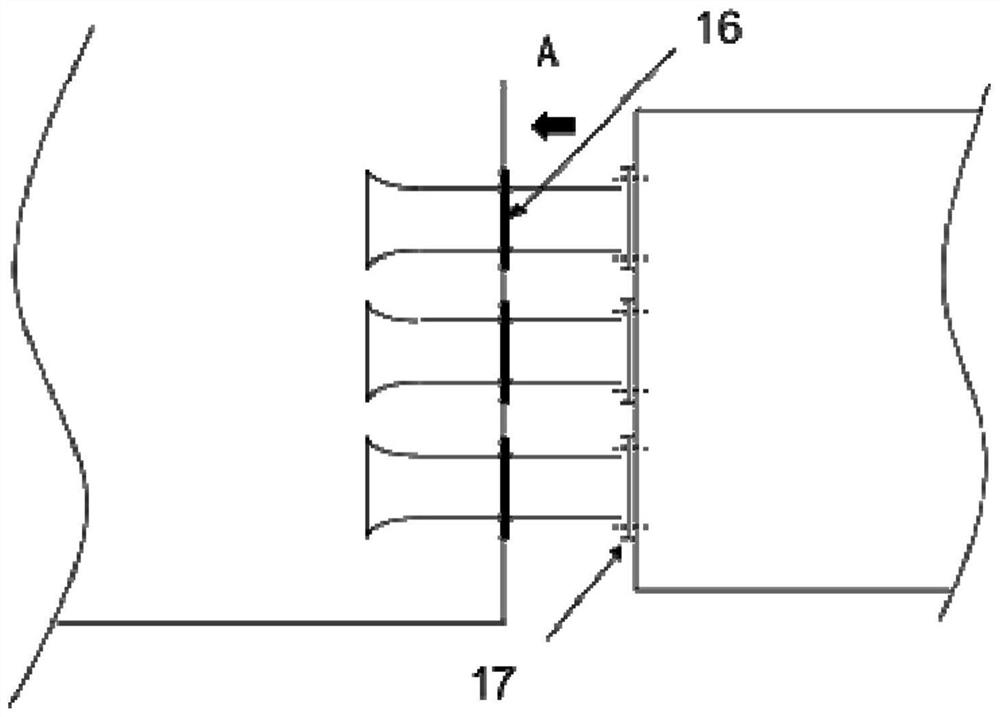

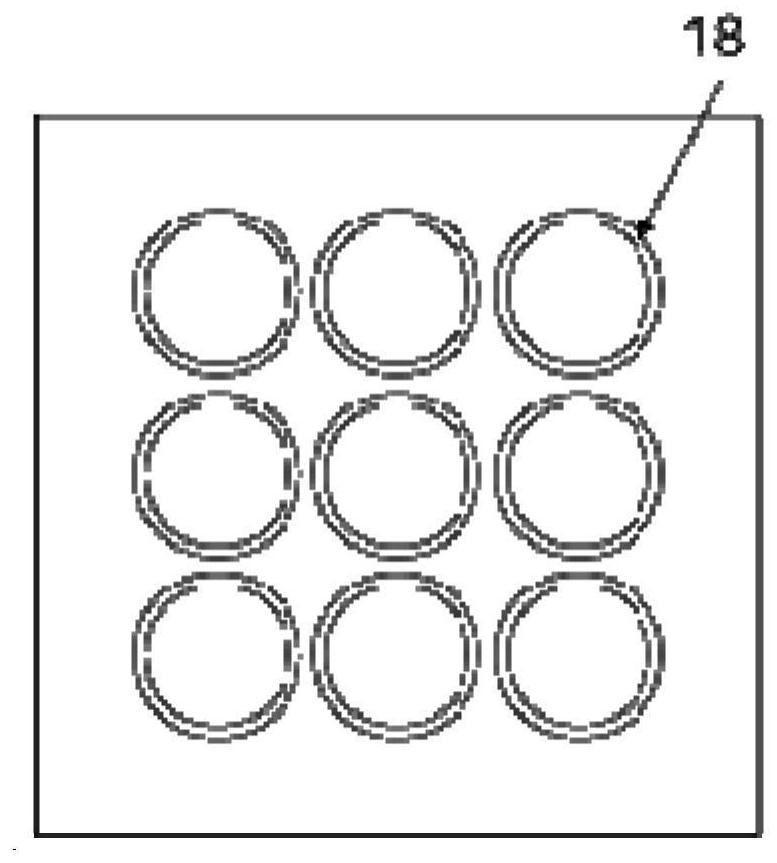

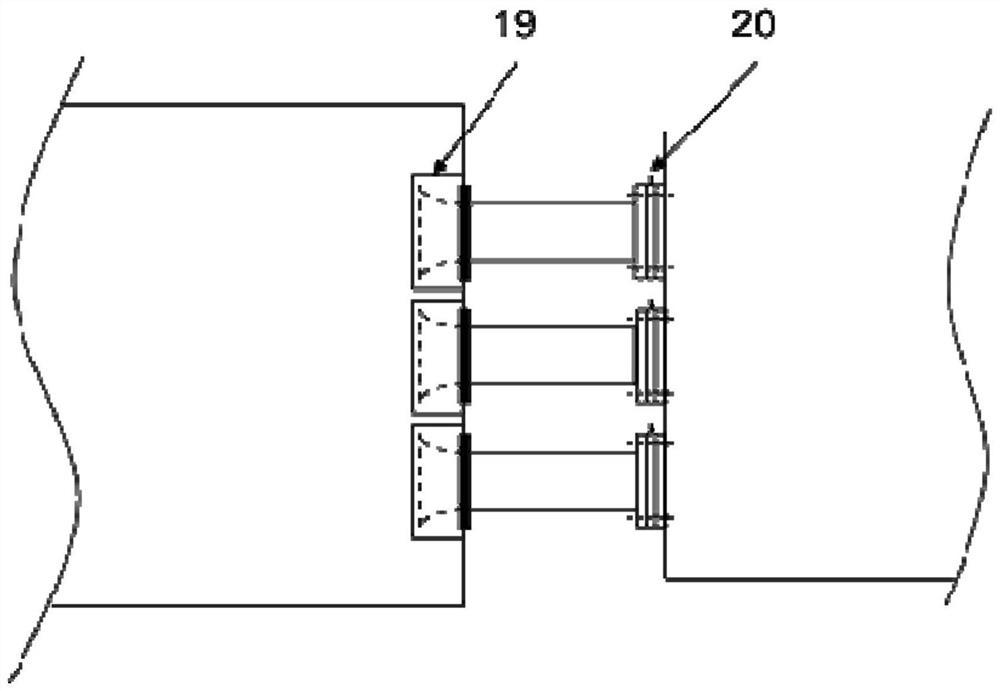

[0045] The intake air flow nozzle assembly provided in this embodiment is used in an intake air flow measuring device.

[0046] See Figure 1 to Figure 7 And combine Picture 8 As shown, the intake air flow nozzle assembly in this embodiment includes a plurality of nozzle flow meters 6 and a connecting seat with a plurality of connecting through holes 22 arranged in an array, and the nozzle flow meters 6 are arranged in the connecting through holes in one-to-one correspondence. Within 22. The connecting seat provided with the connecting through hole 22 provides support and fixation for each nozzle flowmeter 6, thereby combining a plurality of nozzle flowmeters 6 to form an intake flow nozzle assembly.

[0047] A predetermined number of nozzle flowmeters 6 evenly arranged relative to the connecting seat among the plurality of nozzle flowmeters 6 can be opened at the same time to reach the predetermined intake flow rate through the intake flow measurement range of the intake flow no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com