Method for calculating residual bearing capacity of concrete T-shaped beam by considering influence of fire crack

A calculation method and concrete technology, applied in design optimization/simulation, instrument, geometric CAD, etc., can solve the problems of inaccurate calculation of cross-section temperature field, affecting the calculation accuracy of residual bearing capacity after disasters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

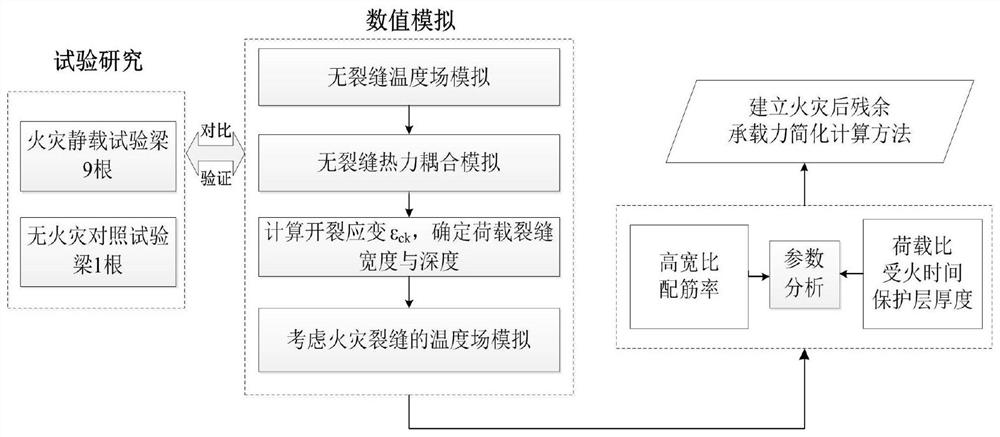

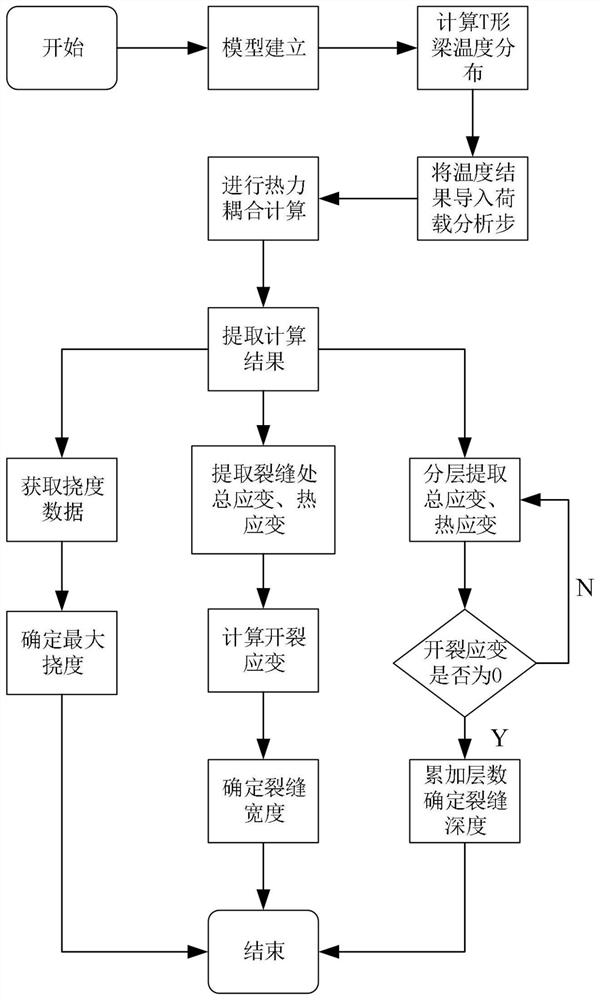

Method used

Image

Examples

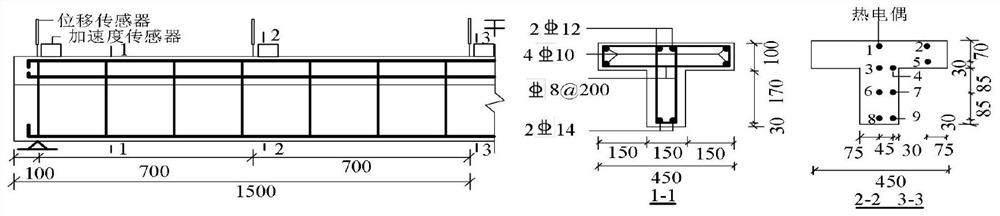

experiment example

[0122] According to the calculation method disclosed in the present invention, the relevant experimental data for calculating the residual bearing capacity of concrete T-shaped beams after fire are as follows:

[0123] 1. Crack related data:

[0124] Table 1 Data related to crack width

[0125]

[0126] Table 2 Data related to fracture depth

[0127]

[0128] 2. Analysis of influencing factors of residual bearing capacity:

[0129] Table 3 Concrete T-beam crack width and depth (mm) under different working conditions

[0130]

[0131]

[0132] 3. Bearing capacity reduction factor:

[0133] Table 4 Reduction coefficient of partial bearing capacity of beams exposed to fire for 120 minutes

[0134]

[0135] Table 5 Reduction coefficient of bearing capacity of beams exposed to fire for 90 minutes

[0136]

[0137]

[0138]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com