Rolling diaphragm pump

A technology for diaphragm pumps and diaphragms, applied to pumps, pump components, pump parameters, etc., can solve problems such as high cost and complex structure, and achieve the effect of suppressing cost increase and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, preferred embodiments of the present invention will be described with reference to the drawings.

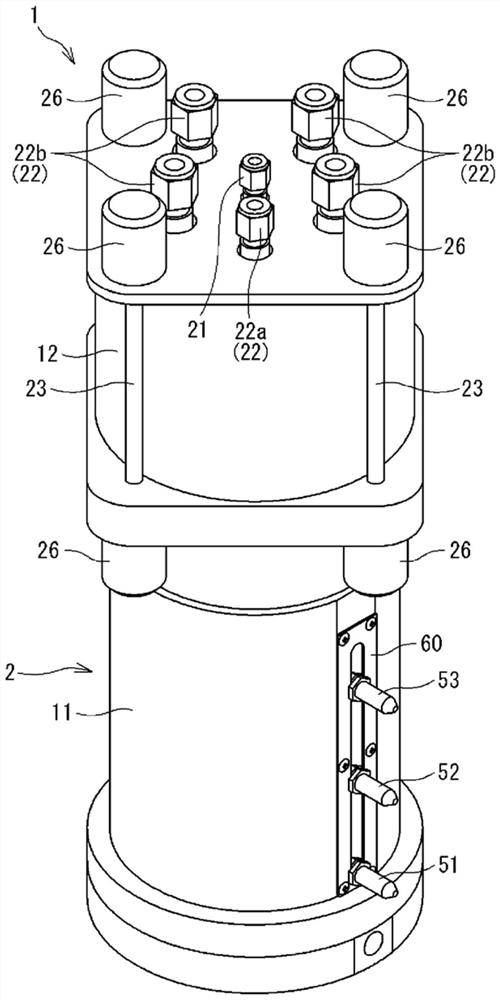

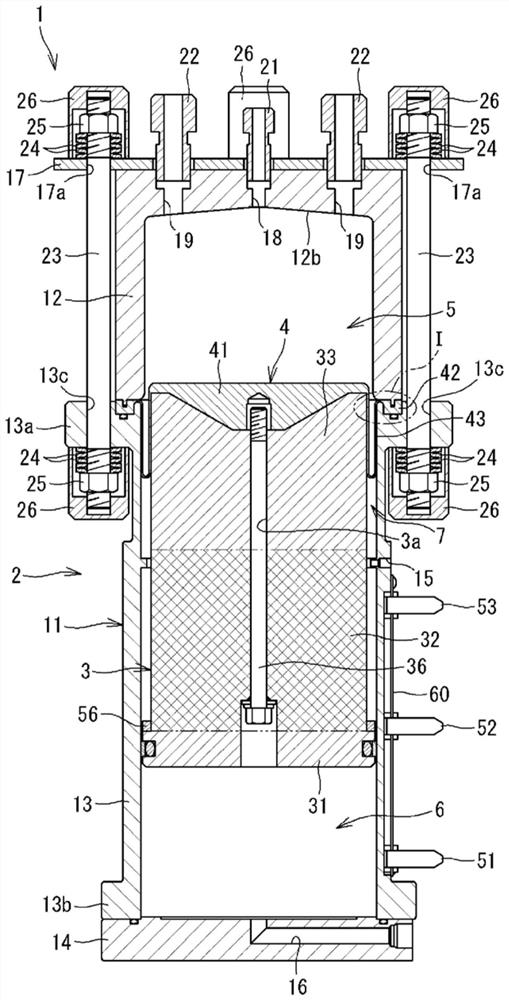

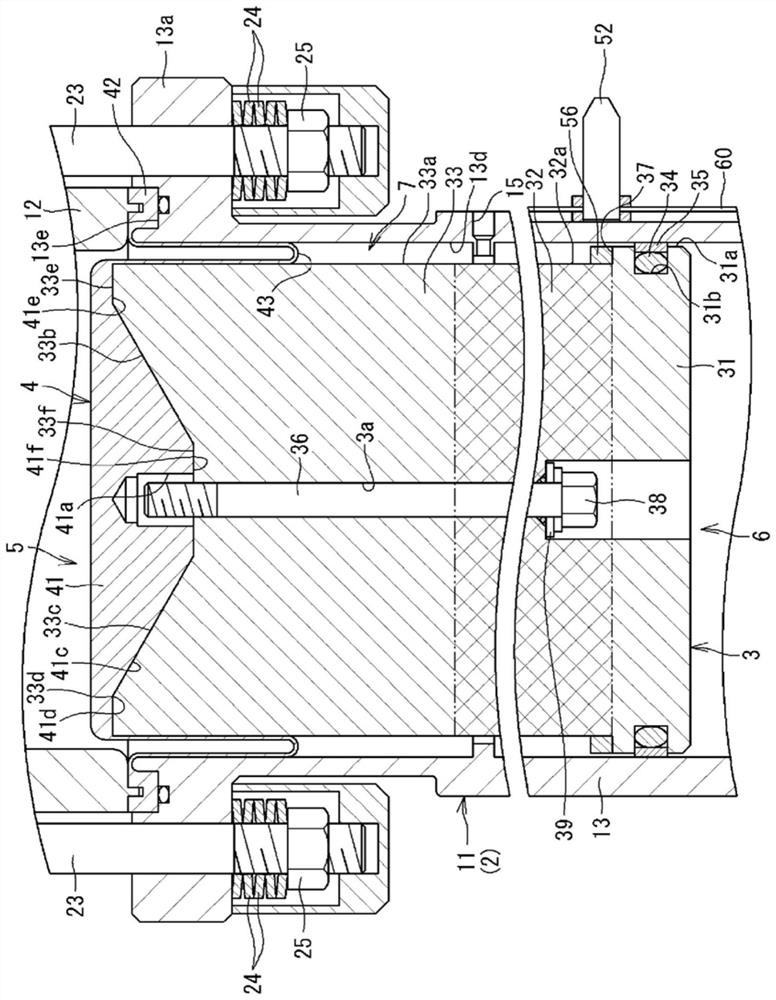

[0029] figure 1 It is a perspective view of the rotary diaphragm pump concerning embodiment of this invention. figure 2 is a sectional view of the rotary diaphragm pump. exist figure 1 and figure 2 Among them, a rotary diaphragm pump 1 has a housing 2 , a piston 3 and a rotary diaphragm 4 . In the present embodiment, the longitudinal direction (axial direction) of the rotary diaphragm pump 1 (hereinafter also simply referred to as the pump 1 ) is arranged in the vertical direction, but it may also be arranged in the horizontal direction.

[0030] [Structure of the case]

[0031] The housing 2 has a cylinder body 11 and a pump head 12 . The cylinder block 11 has: a cylinder main body 13 formed in a cylindrical shape; and a disk-shaped bottom plate 14 fixed to an axial lower end of the cylinder main body 13 . The cylinder main body 13 and the bottom plate 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com