A safety support device for maintenance of rotary cultivator

A technology of safety support and rotary tiller, applied in the field of rotary tiller, can solve the problems that the body of the rotary tiller is easy to fall suddenly, the fixed operation of the rotary tiller is troublesome, and the size of the rotary tiller is different, so as to reduce the limitations, Reduces instability and avoids slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

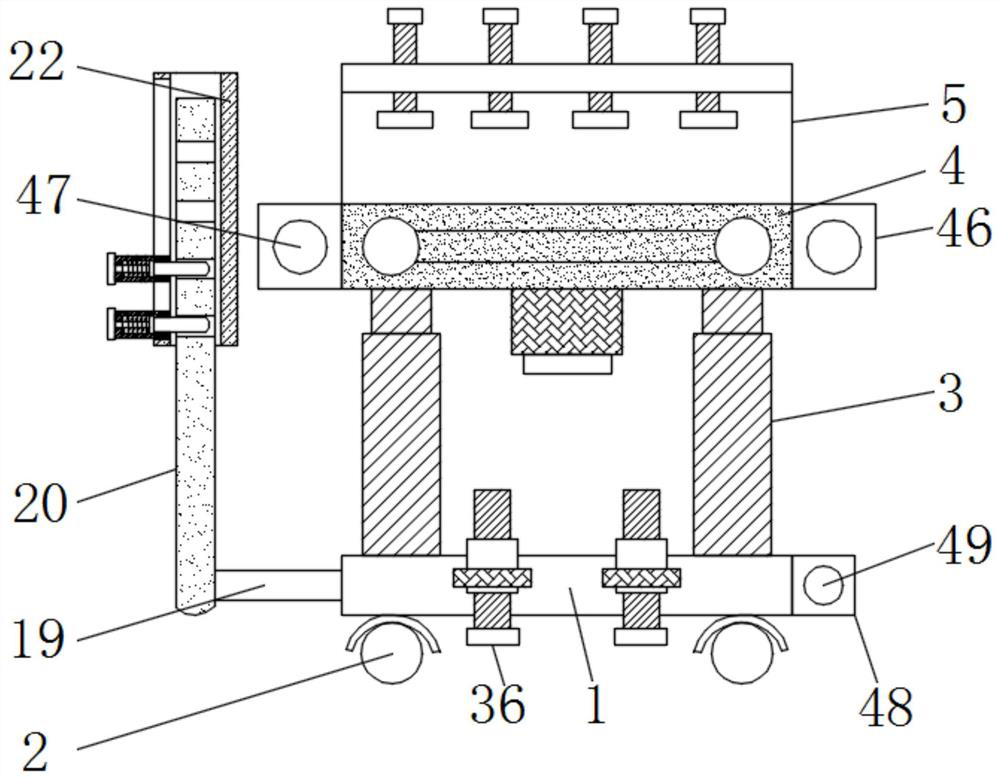

[0039] see Figure 1-10 According to an embodiment of the present invention, a safety supporting device for repairing and maintaining a rotary tiller includes a bottom plate 1, universal wheels 2 are fixedly connected to the four corners of the bottom of the bottom plate 1, and the universal wheels 2 are fixed universal wheels. To the wheel, the two sides of the base plate 1 are connected with a stabilizing mechanism, and the top of the base plate 1 is fixedly connected with two jacks 3, and the top of the jack 3 is fixedly connected with a placement plate 4, and the placement plate 4 The top of the top is provided with a limit frame 5, and the shape design of the limit frame 5 is similar to L type;

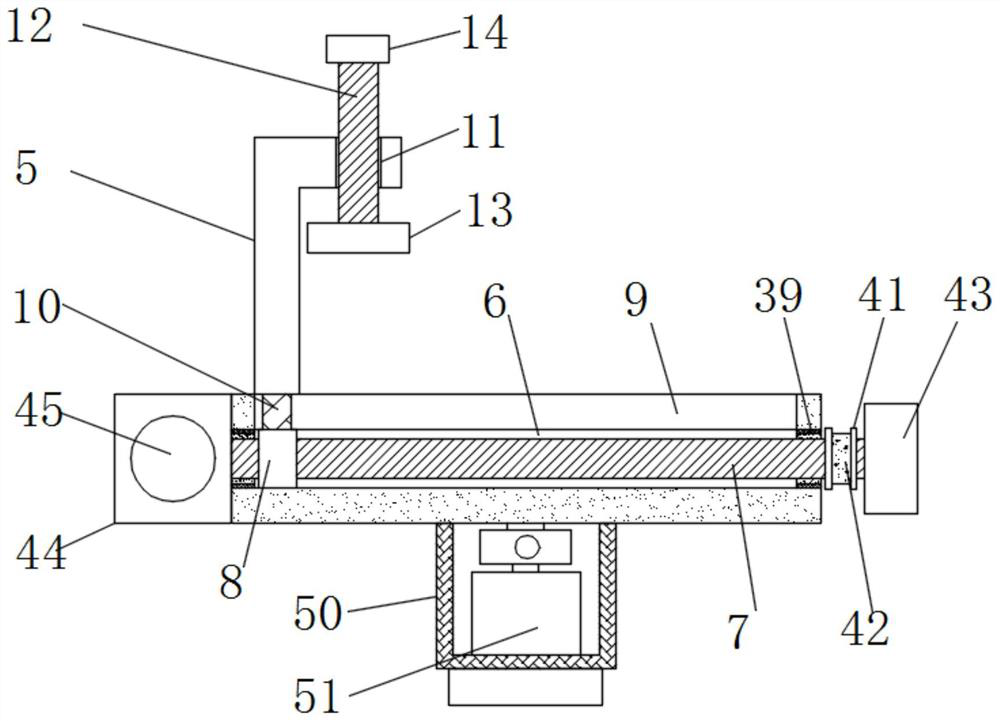

[0040] The inner two sides of the placement plate 4 are provided with a cavity one 6, and the inside of the cavity one 6 is provided with a screw rod two 7, and the screw rod two 7 is movably connected with the cavity one 6 through a connecting mechanism, the The connection mech...

Embodiment 2

[0046] see figure 1 and Figure 6 , the stabilizing mechanism includes connecting block 2 33, threaded sleeve 34, screw rod 3 35 and fixing block 36, the two sides of the bottom plate 1 are fixedly connected with connecting block 2 33, and the inside of the connecting block 2 33 is fixedly connected with thread The inner thread of the threaded sleeve 34 of the cover 34 is connected with a screw rod three 35, and the bottom of the screw rod three 35 is fixedly connected with a fixed block 36, and the stabilizing mechanism can improve the stability of the bottom plate 1, and further reduce the inadequacy of the support device when supporting. Stable case for increased safety when braced.

Embodiment 3

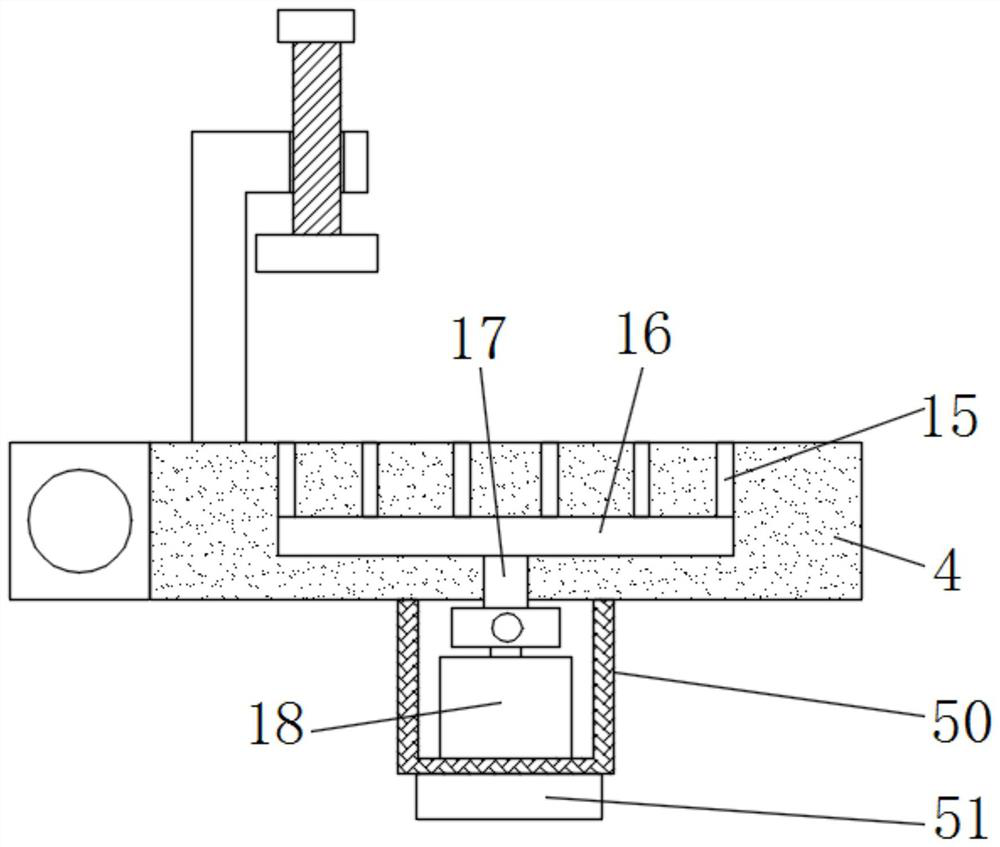

[0048] see Figure 9-10 , the limiting mechanism includes a limiting block 37 and a limiting groove 38, the two sides of the slider 24 are fixedly connected with the limiting block 37, and the movable opening 23 is limited by the side wall close to the limiting block 37 Groove 38, the limiting block 37 is located in the limiting groove 38 and matches with the limiting groove 38, the limiting mechanism plays the role of limiting, which can prevent the slider 24 from breaking away from the movable opening 23, so that the sliding The block 24 can effectively slide inside the movable opening 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com