Transmission device suitable for stable take-up and pay-off of spool

A transmission device and I-shaped wheel technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve the problems of site pollution, unstable running tension, and uneven tension of the winding line, and achieve high work efficiency, stable transmission, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

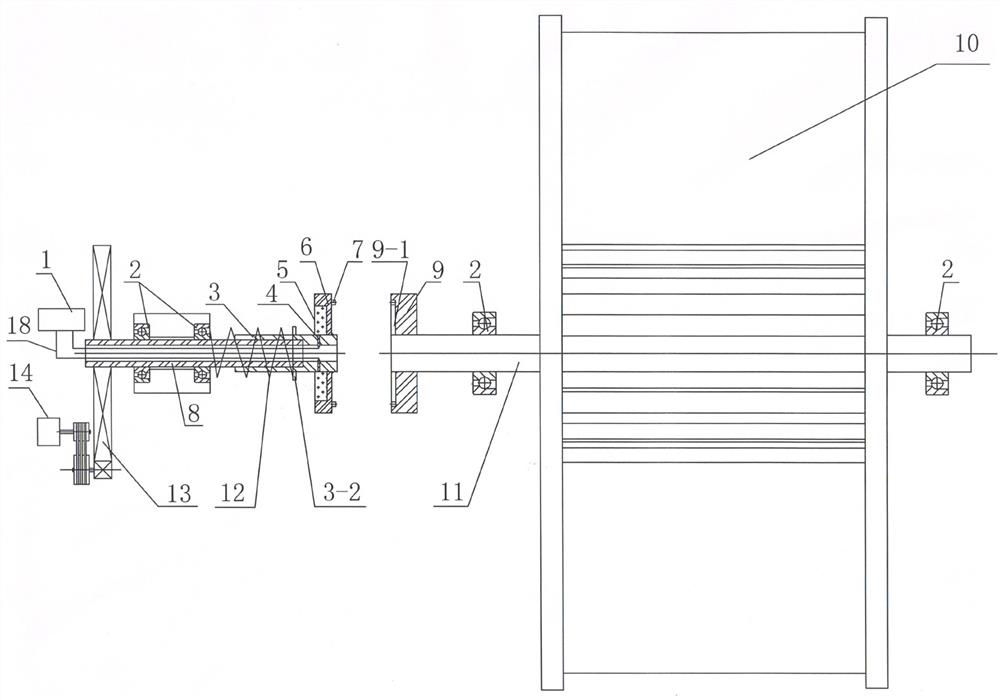

[0023] Embodiment 1 (Embodiment 1 is used as a power device for active take-up)

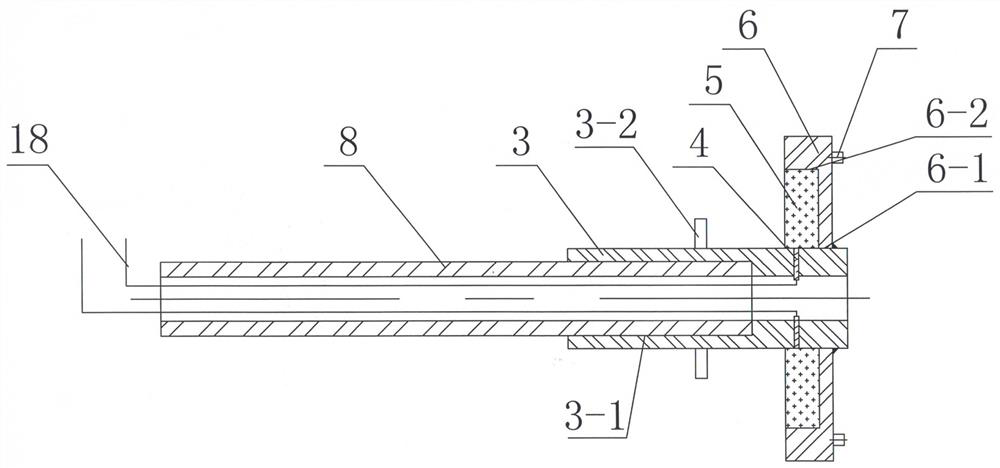

[0024] Such as Figure 1 ~ Figure 4 As shown, a transmission device of the present invention suitable for the smooth take-up and pay-off of the I-shaped wheel according to the first embodiment includes a force transmission shaft 8 driven by a force application device, a telescopic shaft 3 set on the output end of the force transmission shaft, and fixed on the telescopic The magnetic power disc 6 at the output end of the shaft (the force device generates power or resistance, and the power or resistance is transmitted to the magnetic power disc 6 through the force transmission shaft 8 and the telescopic shaft 3), and the soft magnetic core 5 embedded in the magnetic power disc, The I-shaped wheel rotating disk 9 installed on the input end of the I-shaped wheel shaft 11 rotates synchronously with the magnetic power plate through electromagnetic attraction, and the I-shaped wheel 10 set on the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com