Iron sheet cutting and length adjustment device based on machining

A technology of length adjustment and mechanical processing, which is applied in the field of mechanical processing, can solve problems such as troublesome operation, increase operator labor force, and reduce the efficiency of iron sheet cutting and processing, and achieve the effect of improved processing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

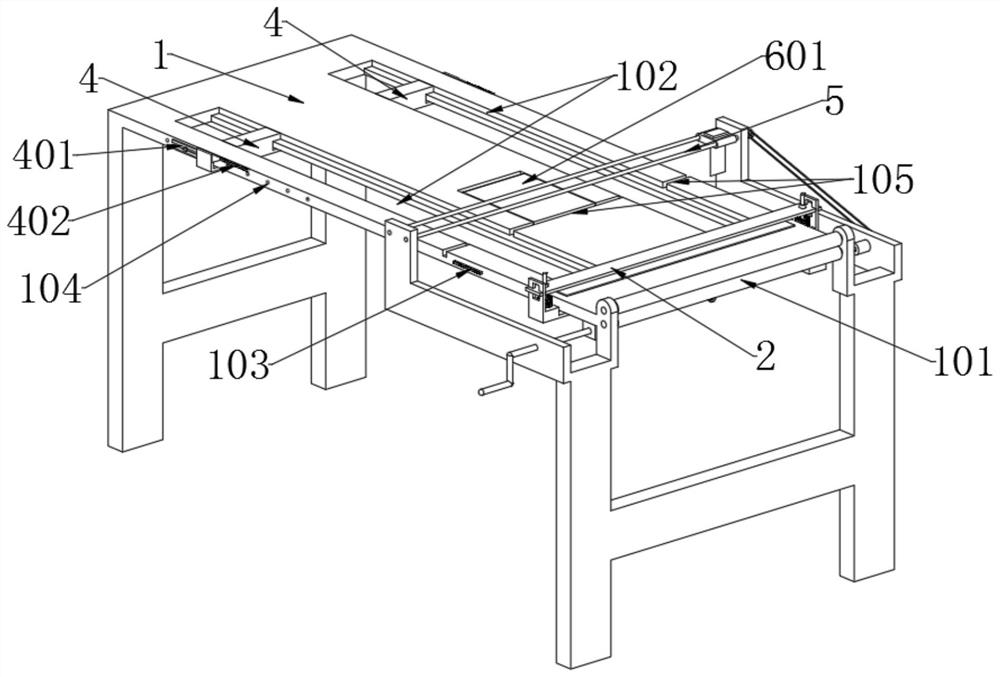

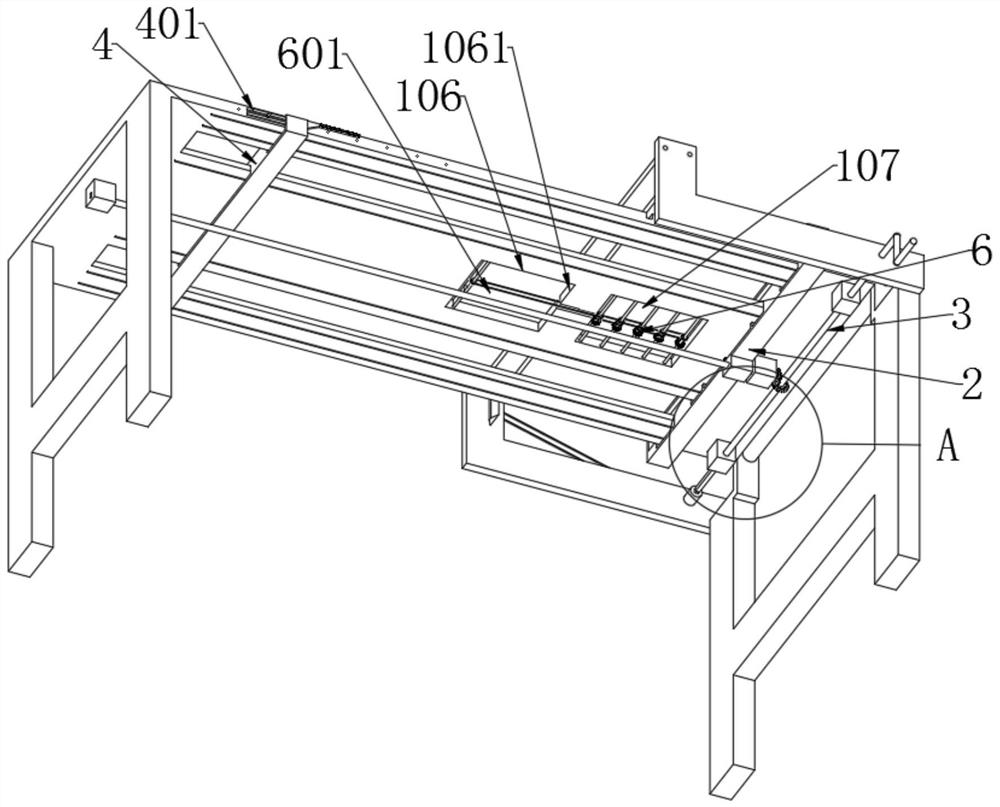

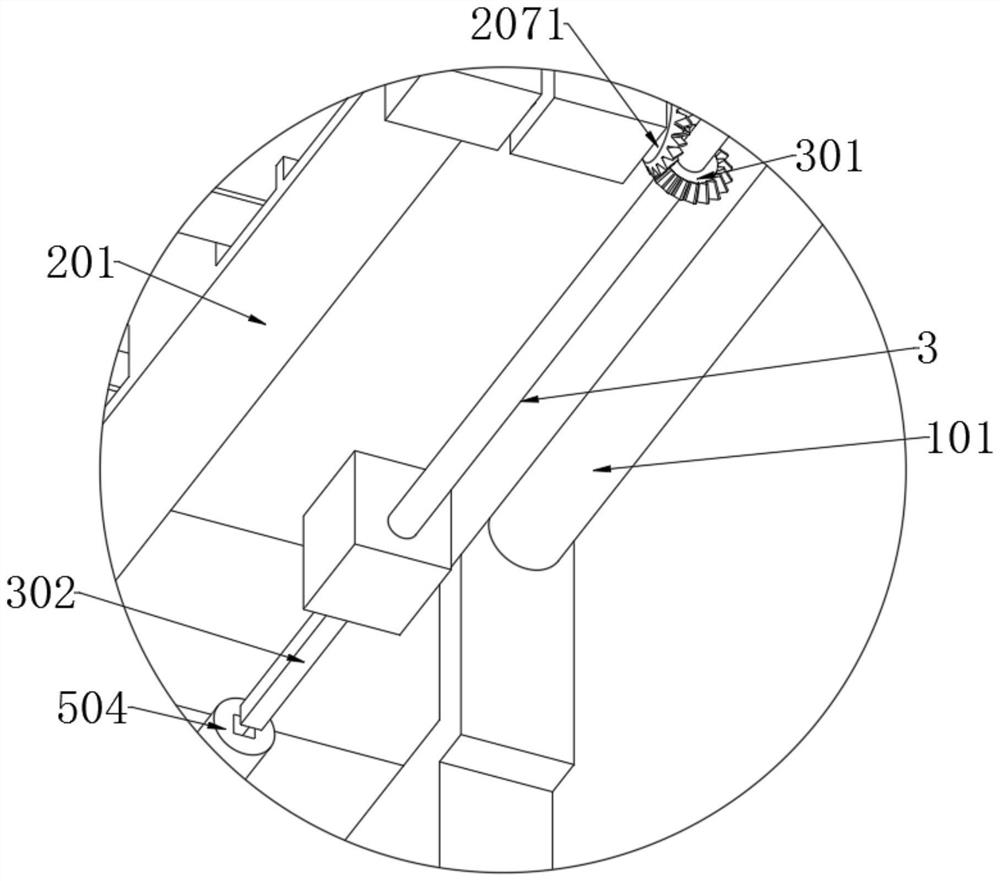

[0042] as attached figure 1 To attach Figure 16 Shown:

[0043] The present invention provides a metal sheet cutting and length adjustment device based on mechanical processing, which includes a processing table body 1, a cutting length clamping plate 4, and a discharge mechanism 6; two sets of transverse chute 102 are provided on the processing table body 1, And the press-fit pulling mechanism 2 is slidably installed in the transverse chute 102, and the cutting length clamping plates 4 are respectively slidably installed on the other end of the transverse chute 102, and the bottoms of the two groups of cutting length clamping plates 4 are connected together, The two outer ends of the cutting length clamping plate 4 are respectively connected with U-shaped adjusting plates 401, and the U-shaped adjusting plate 401 and the processing table body 1 are screwed into the side threaded holes 104 by bolts to lock and fix the side threaded holes 104 It is arranged on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com