Molding method of bio-based filler modified polylactic acid composite material product

A composite material and molding method technology, applied in the field of composite material processing, can solve the problems of carbonization, high cost of main materials, damage to the original performance of bamboo fibers, etc., and achieve the effects of small shear force and improved feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

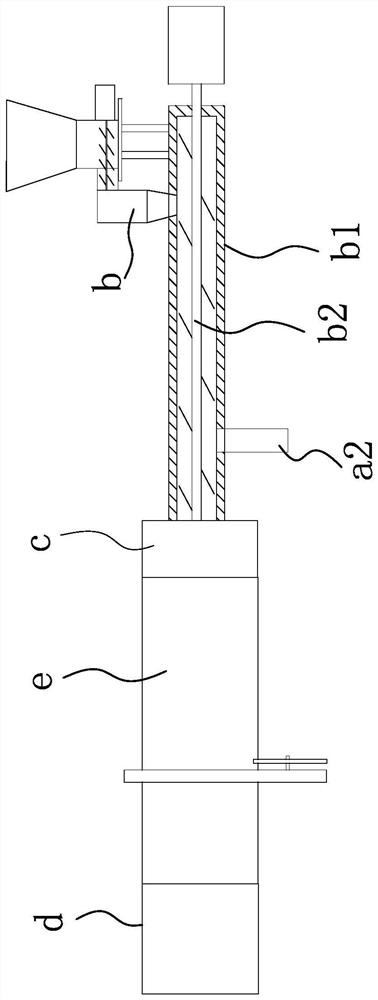

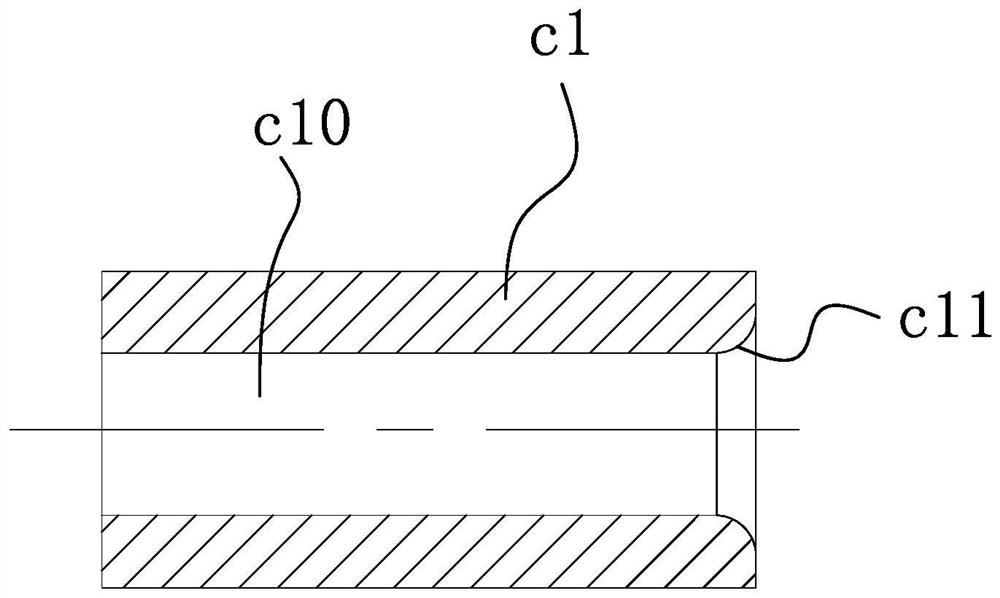

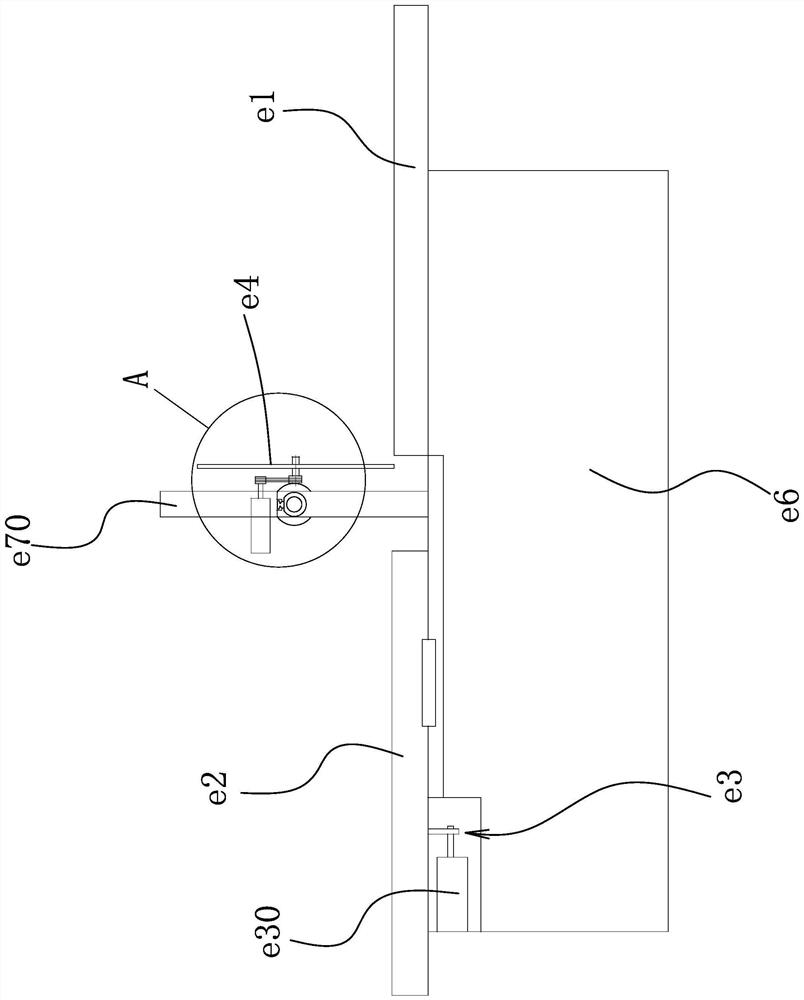

[0056] Such as figure 1 As shown, the molding method of the bio-based filler modified polylactic acid composite product, the die-casting method is based on the die-casting production line, the die-casting production line includes a conveying channel b1, and a feeding screw b2 pierced in the conveying channel b1, The feeding screw b2 is connected to the main feeding motor. Of course, in order to improve the stability of the rotation of the feeding screw b2, a gearbox is connected to the output shaft of the feeding main motor, and the feeding screw b2 is connected to the gear box, as well as to the transmission The heating mechanism for passage b1, the heating mechanism includes a steam pipe surrounding the outer wall of the conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com