Preparation process of environment-friendly adsorption material

A technology of adsorption material and preparation process, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of fast adsorption and desorption rate, weak binding force, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

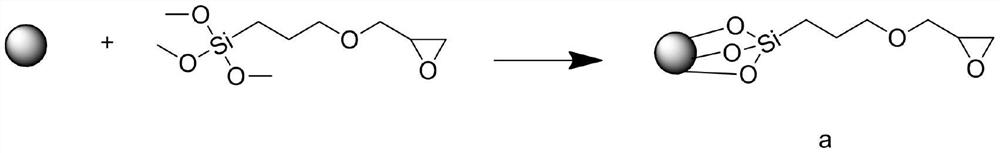

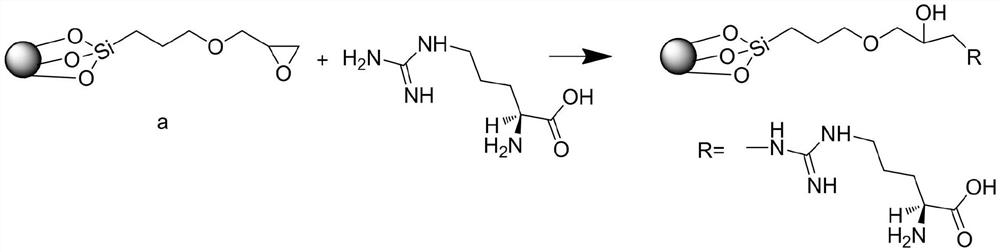

Method used

Image

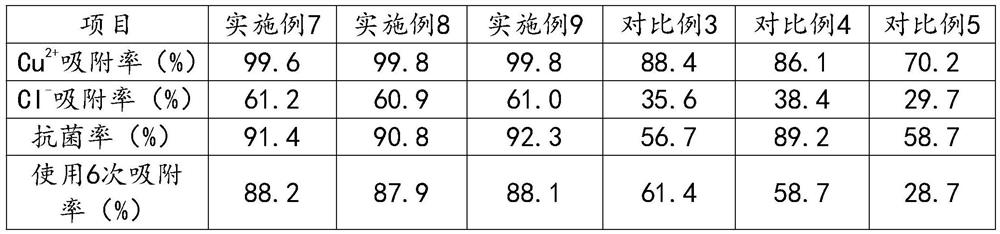

Examples

Embodiment 1

[0028] Modified chitosan is made by the following steps:

[0029] Step A1, add 0.1mol chitosan and 160mL acetic acid solution with a mass fraction of 1% into a round bottom flask, stir for 4 hours at room temperature, then add a 35% mass fraction of sodium hydroxide solution to adjust the pH value to 7, and then transfer Place in an ice bath, control the reaction temperature at 0°C, add 0.1 mol of 2-chloroethoxyacetonitrile dropwise to the round bottom flask with a constant pressure dropping funnel, after the addition is complete, raise the temperature to 60°C, and continue to stir for 4 hours. After the reaction, add 35% sodium hydroxide solution into the round bottom flask to adjust the pH to 7, then purify and wash with methanol and acetone three times, and finally dry in an oven at 60°C to constant weight to obtain intermediate 1;

[0030] Step A2, add 1 g of intermediate 1 and 28 mL of methanolic aqueous solution of hydroxylamine hydrochloride with a mass fraction of 3% i...

Embodiment 2

[0033] Modified chitosan is made by the following steps:

[0034] Step A1, add 0.1mol chitosan and 185mL mass fraction of 1% acetic acid solution into a round bottom flask, stir for 5h at room temperature, then add 35% mass fraction of sodium hydroxide solution to adjust the pH value to 7, then Transfer to an ice bath, control the reaction temperature at 3°C, add 0.1mol of 2-chloroethoxyacetonitrile dropwise to the round bottom flask with a constant pressure dropping funnel, after the addition, raise the temperature to 60°C, and continue stirring for 5h After the reaction, add 35% sodium hydroxide solution to the round bottom flask to adjust the pH to 7, then purify and wash with methanol and acetone three times, and finally dry in an oven at 60°C to constant weight to obtain intermediate 1;

[0035] Step A2, add 1g of intermediate 1 and 33mL of methanolic aqueous solution of hydroxylamine hydrochloride with a mass fraction of 3% in a three-necked flask, control the reaction t...

Embodiment 3

[0038] Modified chitosan is made by the following steps:

[0039] Step A1, add 0.1mol chitosan and 220mL acetic acid solution with a mass fraction of 1% into a round bottom flask, stir at room temperature for 6h, then add a 35% mass fraction of sodium hydroxide solution to adjust the pH value to 8, and then transfer In an ice bath, control the reaction temperature at 5°C, dropwise add 0.1mol of 2-chloroethoxyacetonitrile into the round bottom flask with a constant pressure dropping funnel, after the addition, raise the temperature to 60°C, and continue stirring for 6h. After the reaction, add 35% sodium hydroxide solution into the round bottom flask to adjust the pH to 8, then purify and wash with methanol and acetone three times, and finally dry in an oven at 60°C to constant weight to obtain intermediate 1;

[0040] Step A2, add 1g of intermediate 1 and 35mL of methanolic aqueous solution of hydroxylamine hydrochloride with a mass fraction of 3% in a three-necked flask, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com