Film sticking machine

A film laminating machine and film laminating technology, which is applied in packaging and other directions, can solve problems such as equipment crookedness, machine air bubbles, and manual film laminating efficiency, and achieve the effect of wiping thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

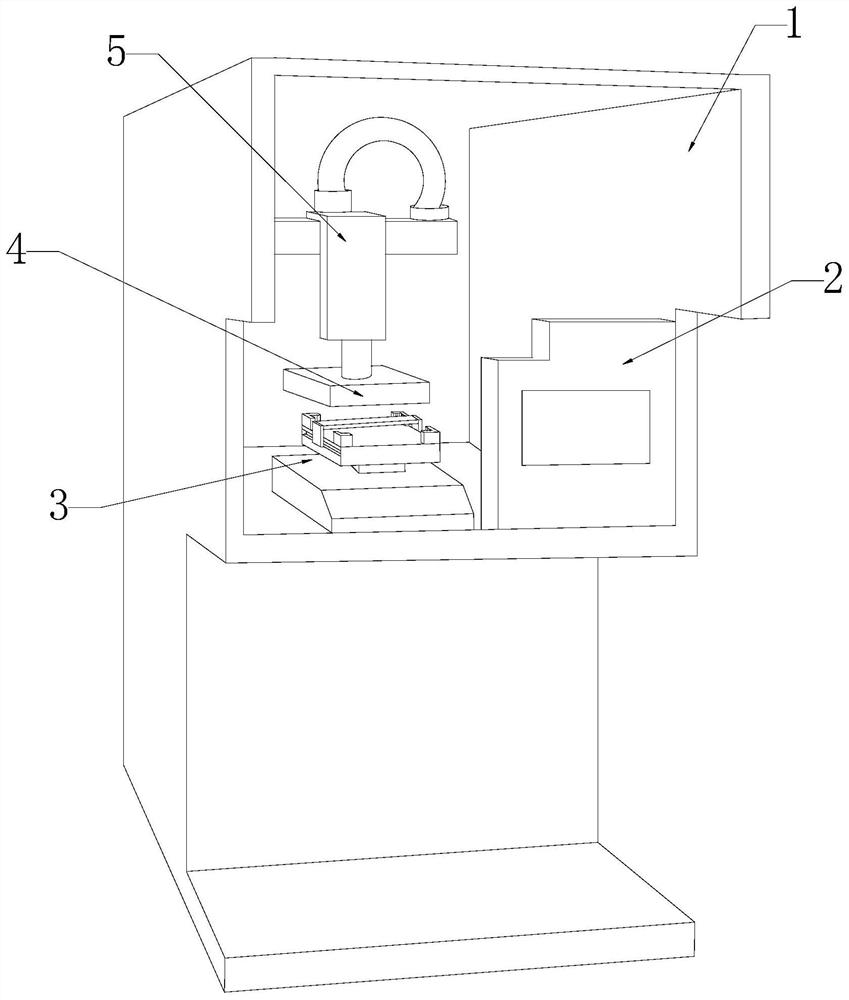

[0030] see Figure 1-Figure 3 , a film laminating machine, the present invention provides a film laminating machine, aimed at the deficiencies of the prior art, the present invention is achieved through the following technical solutions: a film laminating machine, the structure of which includes a body 1, a control box 2, a processor 3 , film plate 4, slider 5, the front of the body 1 is provided with a control box 2, the top of the body 1 is equipped with a slider 5, and the bottom of the slider 5 is connected with the film plate 4 through a connecting shaft, so The body 1 is mechanically connected with the processor 3 .

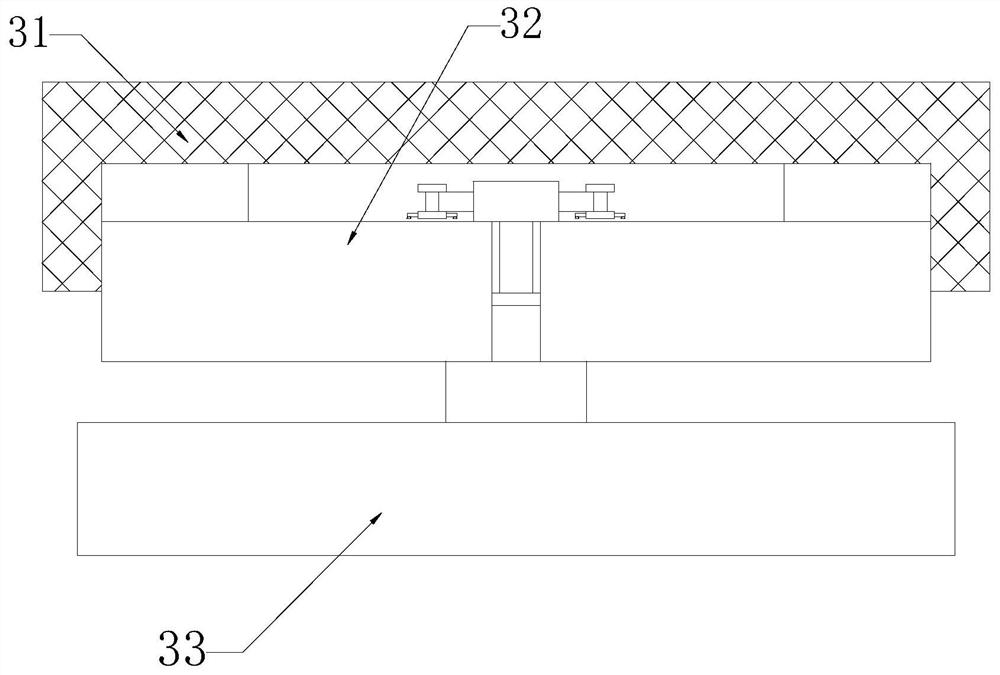

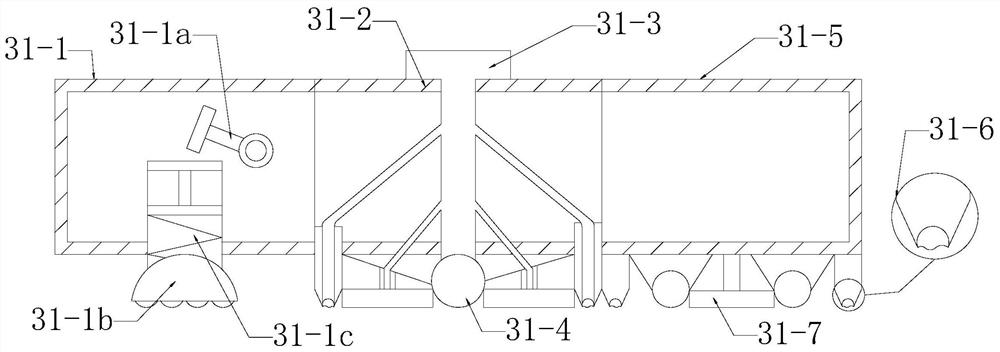

[0031] The processor 3 is composed of a cleaner 31, an adjuster 32, and a support body 33. The cleaner 31 is slidably connected to the adjuster 32, and the adjuster 32 is mechanically connected to the support body 33. The support body 33 is installed on On the top of the body 1, the position adjustment of the mobile phone and the cleaning of the mobile pho...

Embodiment 2

[0038] see Figure 1-Figure 6 , a film laminating machine, the present invention provides a film laminating machine, aimed at the deficiencies of the prior art, the present invention is achieved through the following technical solutions: a film laminating machine, the structure of which includes a body 1, a control box 2, a processor 3 , film plate 4, slider 5, the front of the body 1 is provided with a control box 2, the top of the body 1 is equipped with a slider 5, and the bottom of the slider 5 is connected with the film plate 4 through a connecting shaft, so The body 1 is mechanically connected to the processor 3 .

[0039] The processor 3 is composed of a cleaner 31, an adjuster 32, and a support body 33. The cleaner 31 is slidingly connected to the adjuster 32, and the adjuster 32 is mechanically connected to the support body 33. The support body 33 is installed on On the top of the body 1, the position adjustment of the mobile phone and the cleaning of the mobile phon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com