Manufacturing method of fault fracture zone grouting body similar simulation test piece

A technology similar to the simulation and production method, applied in the preparation of test samples, etc., can solve the problems of inability to objectively simulate the occurrence structure of grouted rock mass in the fault fracture zone, neglect, etc., and achieve low cost of test piece production and convenient test operation , The effect of simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Certain embodiments of the invention will be described more fully hereinafter with reference to the accompanying drawings, in which some, but not all embodiments are shown. Indeed, various embodiments of the invention may be embodied in many different forms and should not be construed as limited to these set forth embodiments; rather, these embodiments are provided so that this invention will satisfy applicable legal requirements.

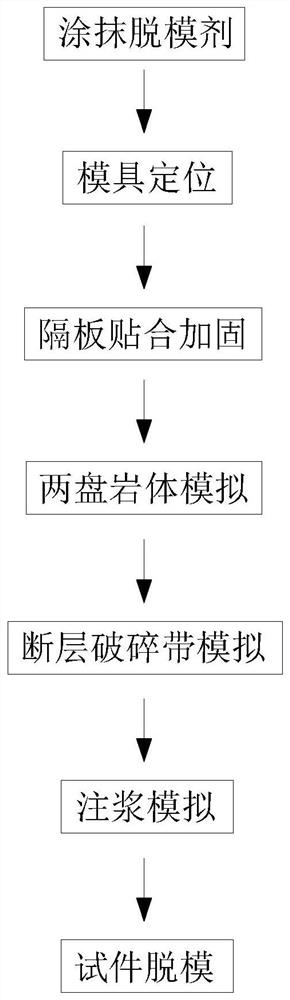

[0046] In the embodiment of the present invention, a method for making similar simulation specimens for grouting in fault fracture zones is provided, please refer to Figure 1 to Figure 4 and Figure 7 shown.

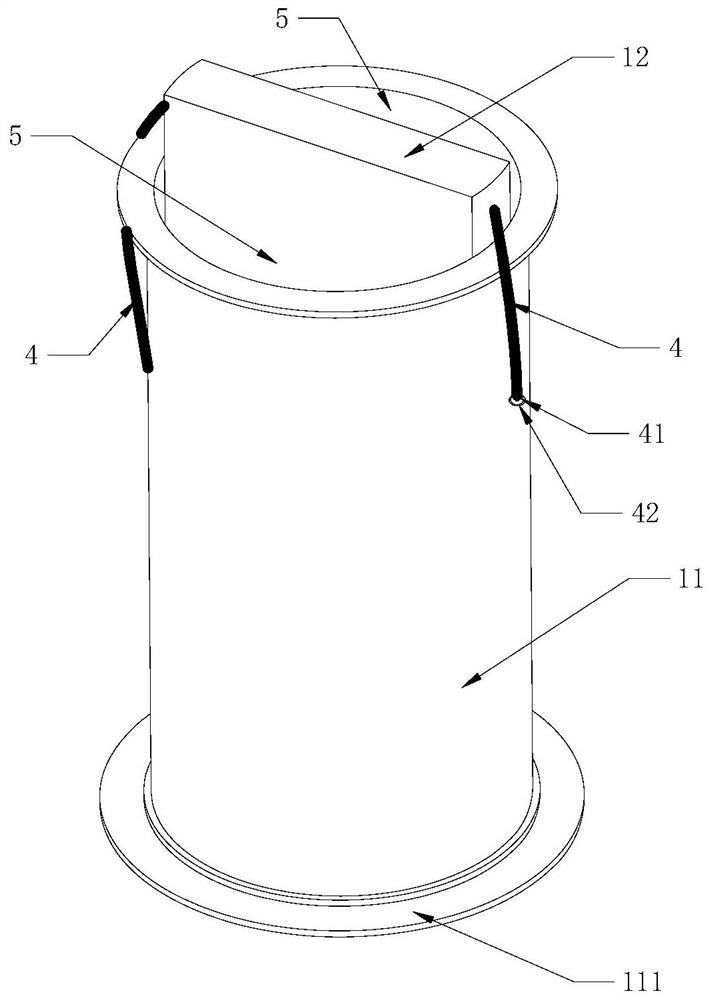

[0047] A method for making a simulated test piece similar to a grouting body in a fault fracture zone. The test piece is used to make a mold. The mold for making the test piece includes a cylinder 11 and a partition 12; the bottom of the cylinder 11 is closed, and the upper end of the cylinder 11 is open. Specifically The cylinder b...

Embodiment 2

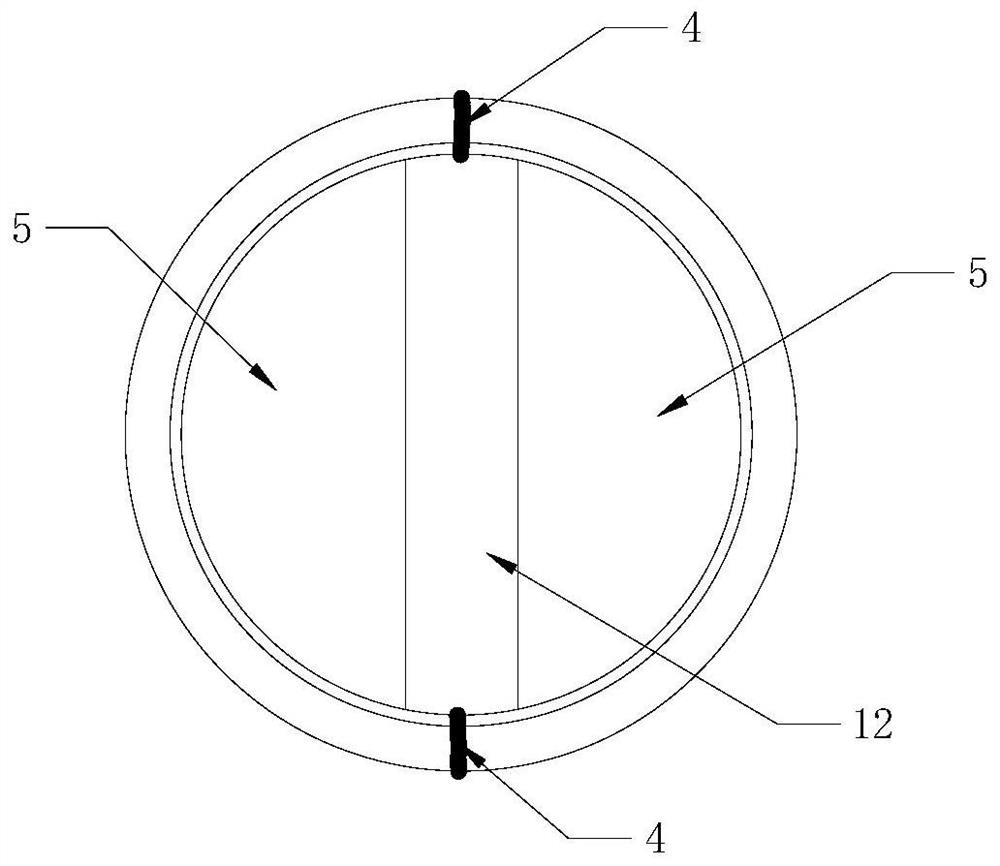

[0070] Such as Figure 5 , Image 6 and Figure 8 As shown, the difference between the present embodiment and the first embodiment is that the partition 12 includes a main body, a left fitting belt 121, a right fitting belt 122 and a lower fitting belt 123, the main body is made of hard plastic, and the left fitting belt The joint band 121, the right joint band 122 and the following joint band 123 can be deformed, and the left joint band 121, the right joint band 122 and the lower joint band 123 are all made of soft plastic. The insides of the left fitting belt 121, the right fitting belt 122 and the lower fitting belt 123 are all provided with positioning strips 3; There is a telescopic body 6, and the telescopic body 6 is connected between the main body and the lower fitting belt 123. The telescopic body 6 is made of elastic material, and the telescopic body 6 is preferably made of rubber material.

[0071] In the second step, the partition 12 is vertically arranged rela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com