Multi-ridge and multi-row peanut windrowing harvesting device

A strip shop and peanut technology, applied in excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve problems such as low overall efficiency and achieve the effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

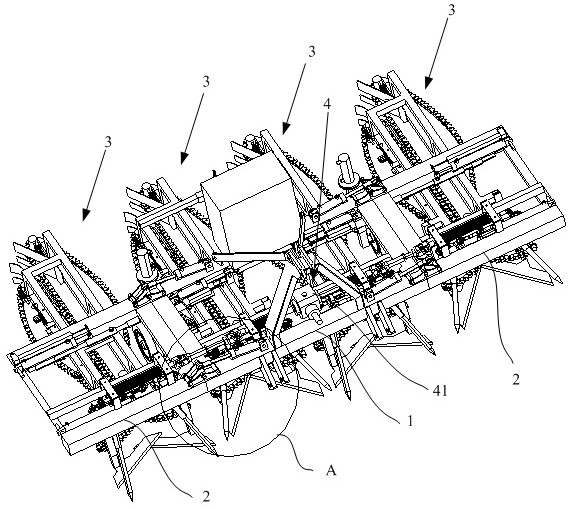

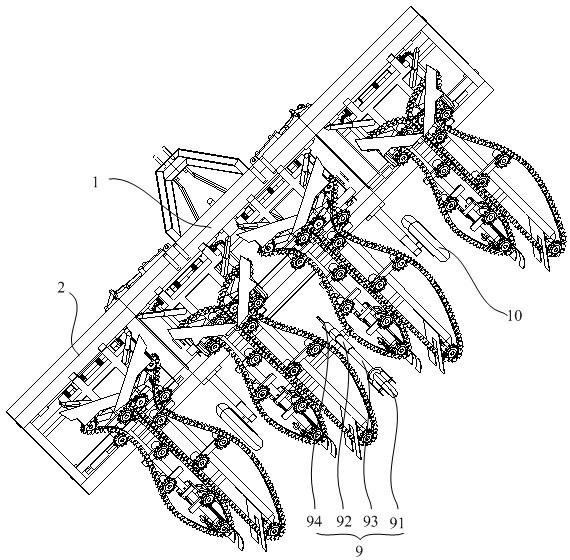

[0015] Such as Figure 1-Figure 7 As shown, the present invention provides a multi-ridge and multi-row peanut strip-laying harvesting equipment, including: an installation frame (not marked), a plurality of strip-laying mechanisms 3 and a driving mechanism 4;

[0016] For different planting areas, the planting spacing of peanuts is also different, and in order to improve versatility, a ridge spacing adjustment mechanism (unmarked) matching the strip laying mechanism 3 is provided on the installation frame; the ridge spacing adjustment mechanism Including the first oil cylinder 6, slide rail 7 and sliding seat 8, the sliding seat 8 is slidably arranged on the slide rail 7, the first oil cylinder 6 is used to drive the sliding seat 8 to slide along the slide rail 7; the mounting frame 31 is arranged on the sliding seat 8 bottom.

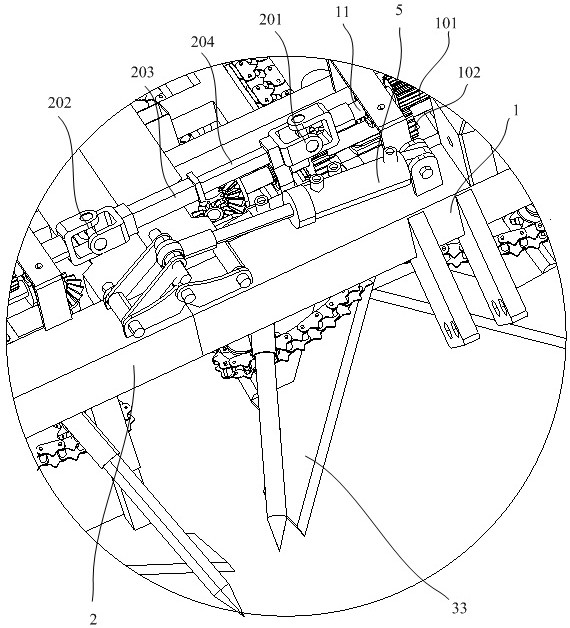

[0017] Wherein, the pavement mechanism 3 comprises a mounting frame 31, a transmission shaft 32, two excavating shovels 33 and two clamping assemblie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com