Novel harvester for arundo donax

A harvester and combine harvester technology, applied in the fields of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of artificial harvesting costs, difficult labor environment, and increased harvesting costs that Luzhu cannot be harvested in time, and achieve significant technical and economical benefits. Advantages, improve the level of agricultural machinery, the effect of low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

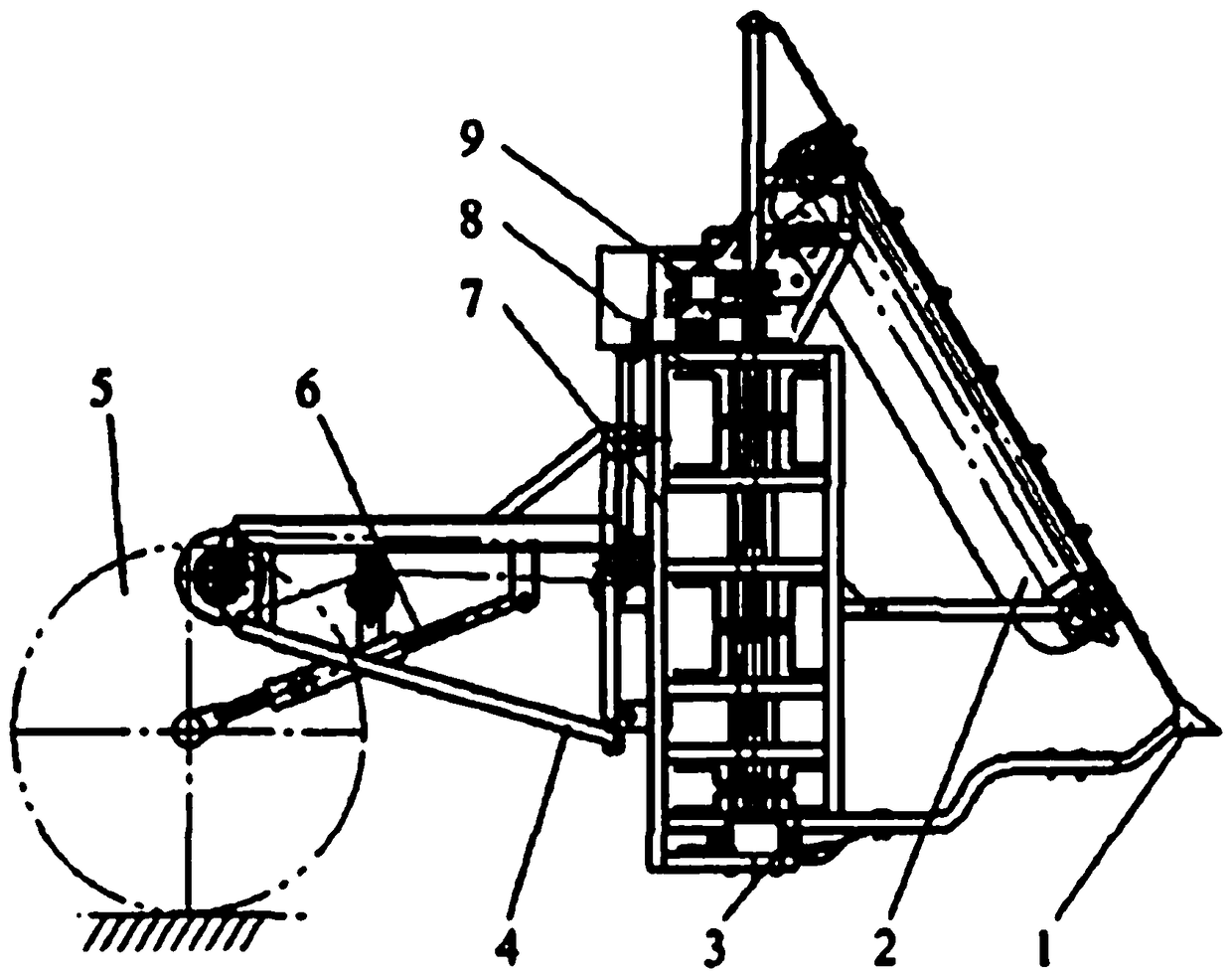

[0017] figure 1 The medium and new type reed bamboo harvester is mainly composed of passive grain dividing mechanism, active grain dividing mechanism, header, suspension mechanism, ground wheel of grain combine harvester, hydraulic lifting system, main frame combination, horizontal conveying mechanism, transmission system, etc.; The cutting platform described above is a sawtooth rotary chain structure, which is mainly composed of active conveyor sprocket combination, driven conveyor sprocket combination, double-pitch chain, moving blade and edge guard, etc., relying on the chain to drive the rotation of the moving blade to achieve support With unsupported cutting, according to the supporting power, the geometric characteristics of the stem height of reed bamboo and the actual production operation requirements, the header is designed to be 2100mm; Saw blades - bimetal helical saw blades, according to the designed cutting width, the blades of the sawtooth rotary chain header are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com