High-speed multi-bag synchronous vacuum shaping packaging machine

A packaging machine and vacuum technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reducing operating speed and affecting packaging output, and achieve the effect of saving floor space, saving waiting time, and improving equipment packaging production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

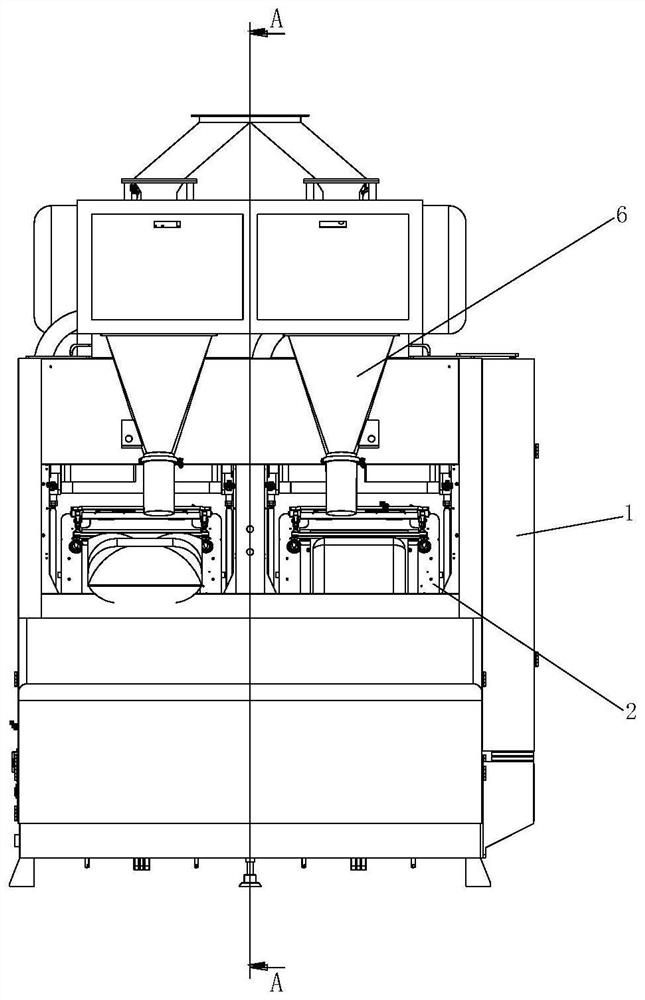

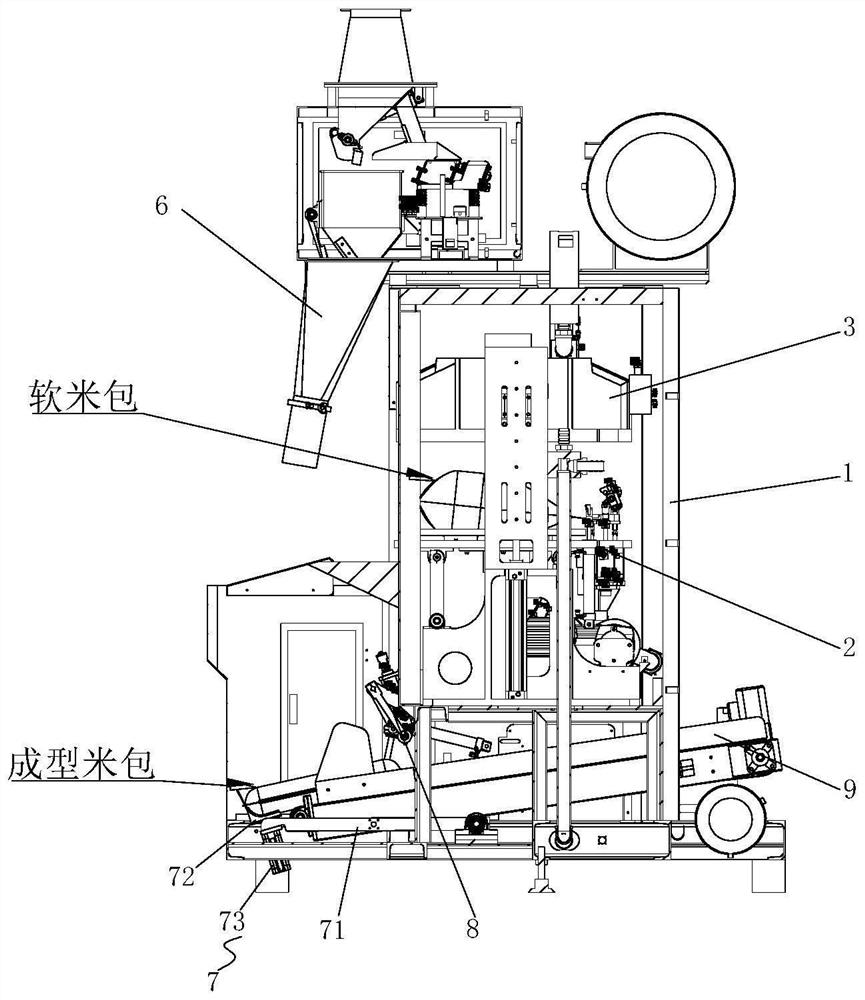

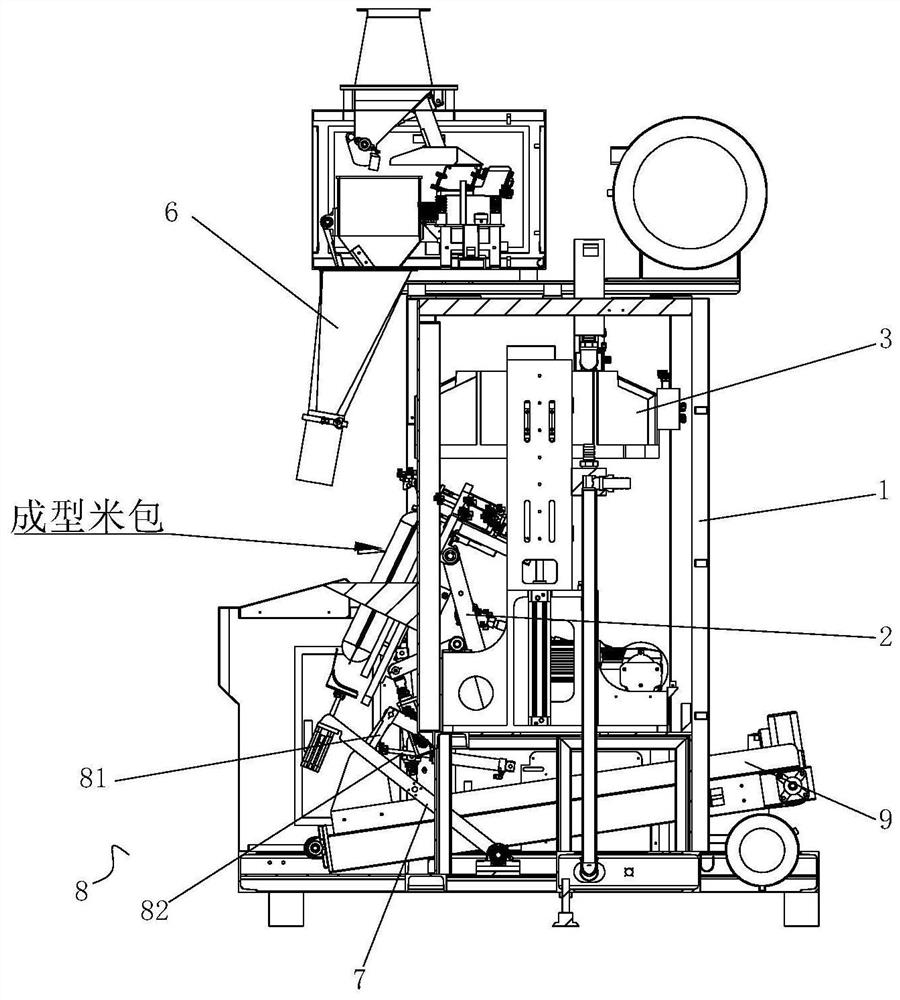

[0023] Such as Figure 1-6 As shown in one of the above, the high-speed multi-bag synchronous vacuum shaping and packaging machine of the present invention includes a frame 1, which has at least two stations that work independently of each other, and the top of the frame 1 is respectively equipped with The filling mechanism 6 is provided with an overturning mechanism 2 on each station and below the corresponding filling mechanism 6, and the top of the overturning mechanism 2 is provided with a vacuum shaping mechanism 3 that can move up and down in the vertical direction; the overturning mechanism 2. It includes a turning plate 21 and an electric drive mechanism 22 that drives the turning plate 21 to rotate. A discharge conveyor belt 9 is provided under the turning plate 21. A rotary sealing mechanism 4 is provided on one end of the turning plate 21 to rotate the sealing mechanism. Mechanism 4 includes a base 41 and a rotating base 42, one end of the rotating base 42 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com