Chain used for conveyor belt type dump semi-trailer

A technology for conveyor belts and semi-trailers, which is applied to conveyors, conveyor objects, vehicles with endless chains/belts, etc., can solve the problem of aggravating the wear between chain parts and sprockets, long oil supply time, and polluting the environment. and other problems, to achieve the effect of slowing down the impact of the bite, improving work efficiency and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

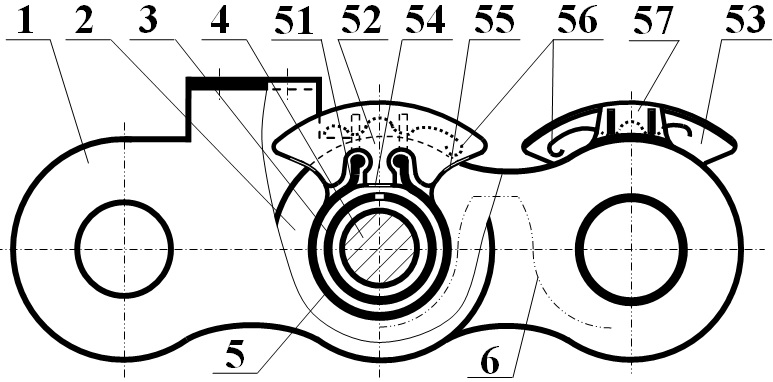

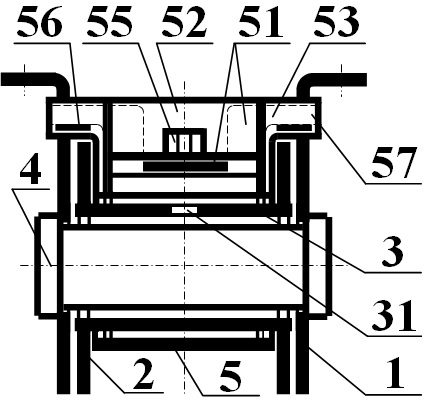

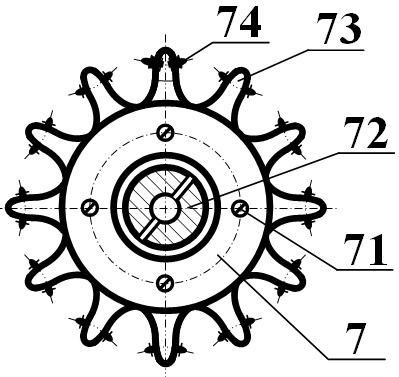

[0058] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. figure 1 It is the front view of the chain of the present invention, figure 2 For the chain of the present invention in figure 1 The right side view of the position; the chain of the present invention includes an outer link plate 1 , an inner link plate 2 , a sleeve 3 , a pin shaft 4 and a roller 5 . The outer chain plate 1, the inner chain plate 2 and the pin shaft 4 are preferably the structure, size and connection relationship of the conveyor chain in the prior art.

[0059] The sleeve 3 is a cylindrical structure with a through hole 31 in the middle of the upper side; the through hole 31 is preferably formed by cutting. The outer chain plate 1 , the inner chain plate 2 , the sleeve 3 and the pin shaft 4 are preferably processed and formed using the metal material and production process of the conveyor chain in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com