A kind of preparation method of copper-based composite material

A technology of copper-based composite materials and composite powders, which is applied in the field of composite materials, can solve problems such as insufficient density of bulk materials, difficult-to-wet interfacial reactions, and influence on thermal conductivity and electrical conductivity of materials, so as to improve the overall comprehensive performance and scope of application Wide and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

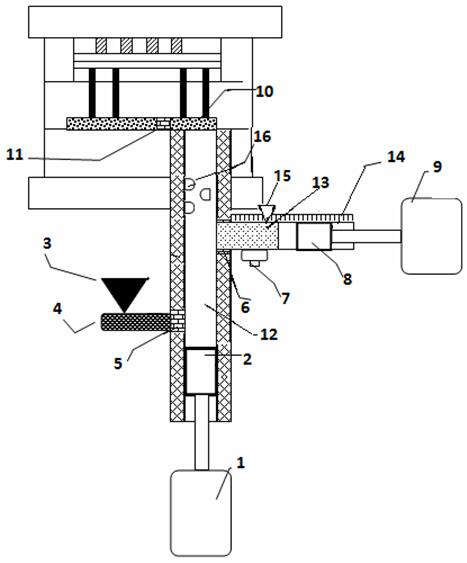

[0030]Apparatus for preparing a copper-based composite material used in the present invention, such asfigure 1 As shown, including a hydraulic pump 1, a piston I2, a smelting furnace 3, a branch pipe I4, a reverse valve I5, a reverse valve II6, a vacuum valve 7, a piston II8, a pneumatic pump 9, a mold cavity 10, and a reverse valve III 11, Main pipe 12, branch pipe II13, scale 14, feed port 15, plurality of turbuler 16, thermal insulation layer, temperature sensor

[0031]The hydraulic pump 1 output is connected to one end of the piston I2, and the other end of the piston I2 is located in the main pipe 12, and the hydraulic pump 1 pushes the piston I2 to travel within the main pipe 12, the other end of the main pipe 12 and the mold cavity 10 inner Unicom, mold cavity 10 Internal entrance sets the stop countervalue III 11;

[0032]The main pipe 12 is connected to the branch pipe I3, a branch pipe II13, a branch pipe II 11, a branch pipeline II13 is closer to the piston I2, branch pipeline...

Embodiment 2

[0035]A method of preparing a copper-based composite, the apparatus of Example 1, the specific steps are as follows:

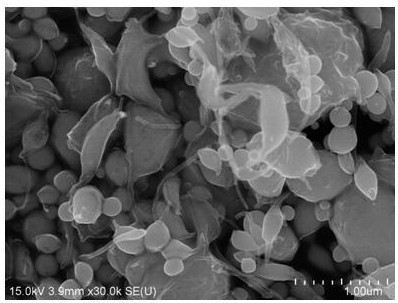

[0036](1) Treatment of carbon nanotubes to treat the carbon nanotube, immerse carbon nanotubes in a mass ratio g: ml of 1: 1, 38% concentrated in concentrated nitric acid, then lyophilized, then dispersed into aqueous solution , Ultrasonic stirring is obtained to obtain a carbon nanotube dispersion, and the mass concentration of the carbon nanotube dispersion is 5% by weight;

[0037](2) The carbon nanotube dispersion of step (1) is added to a mixed liquid, a mixed volume ratio of a mixed liquid, a carbon nanotube dispersion and a tungsten salt solution, a mixed volume ratio of a concentration of 0.01 mol / L. ;

[0038](3) After ultrasonic atomization of the mixture of step (2), the mixture of step (2) is performed into the spray hot solution, and the ultrasonic aerosol is 100 mL / h; the spray thermolyte temperature section includes a preheating section, heating section , ...

Embodiment 3

[0044]A method of preparing a copper-based composite, the apparatus of Example 1, the specific steps are as follows:

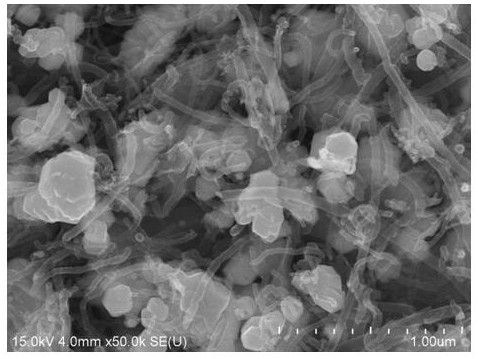

[0045](1) Treatment of carbon nanotubes to treat the carbon nanotube, immersed in concentrated mass fraction of 98% in concentrated sulfuric acid in a mass fraction of 1: 100, and then dispersed evenly after cryogenic acid. In the aqueous solution, ultrasound stirring to obtain a carbon nanotube dispersion, the mass concentration of the carbon nanotube dispersion is 0.1% by weight;

[0046](2) The carbon nanotube dispersion of step (1) is added to the ammonium concentration of 0.02 mol / L to obtain a mixed liquid, the mixed volume ratio of the carbon nanotube dispersion and the tungsten salt solution is 1: 100. ;

[0047](3) After ultrasonic atomization of the mixture of step (2), the mixture of step (2) is introduced into the spray hot solution, and the ultrasonic aerosol is 500 ml / h; the spray thermal solution temperature range includes a preheating section, a heating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com