Melt-blown cloth and preparing system and preparing process thereof

A preparation system and technology of melt-blown cloth, applied in the direction of non-woven fabric, rayon manufacturing, spinneret assembly, etc., can solve the problems of inability to control the width of melt-blown cloth and edge cutting, etc., and achieve density increase and decrease Effect of receiving distance, high loft and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

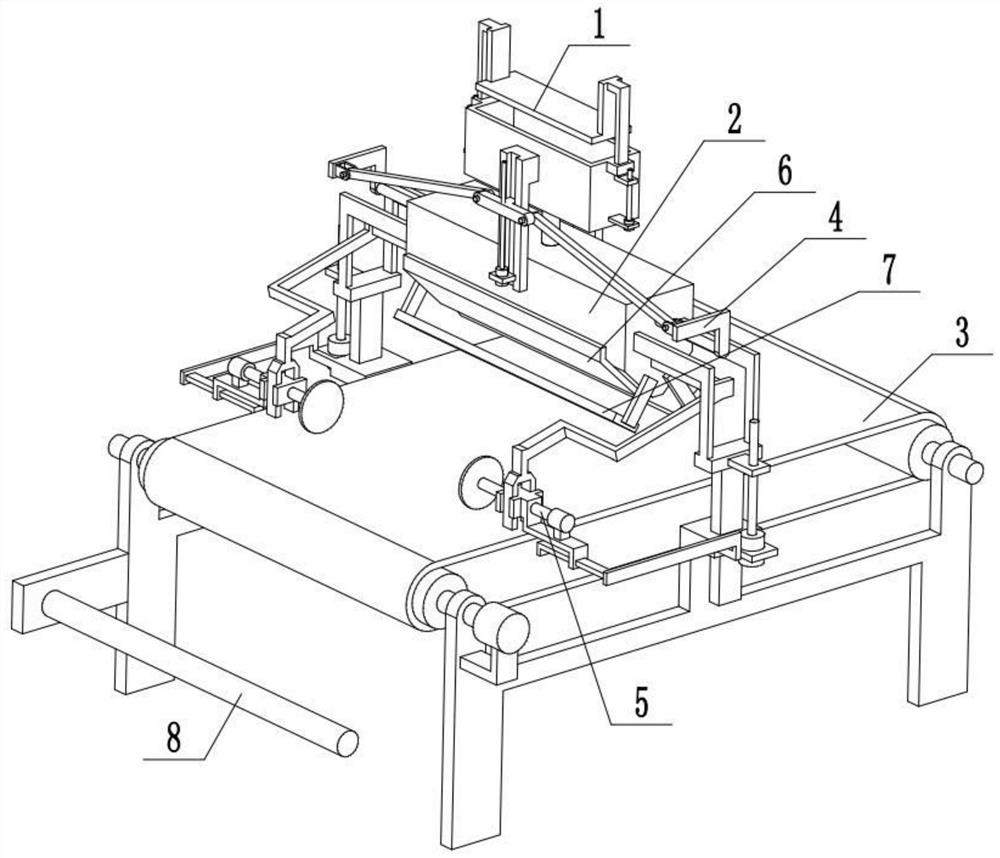

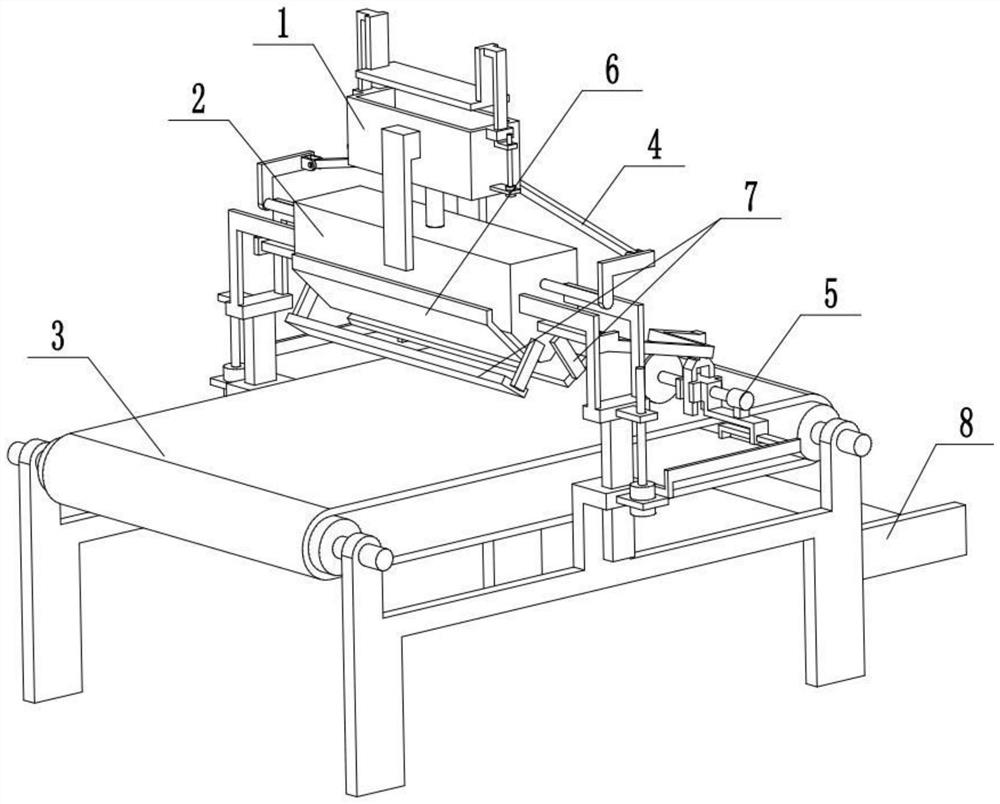

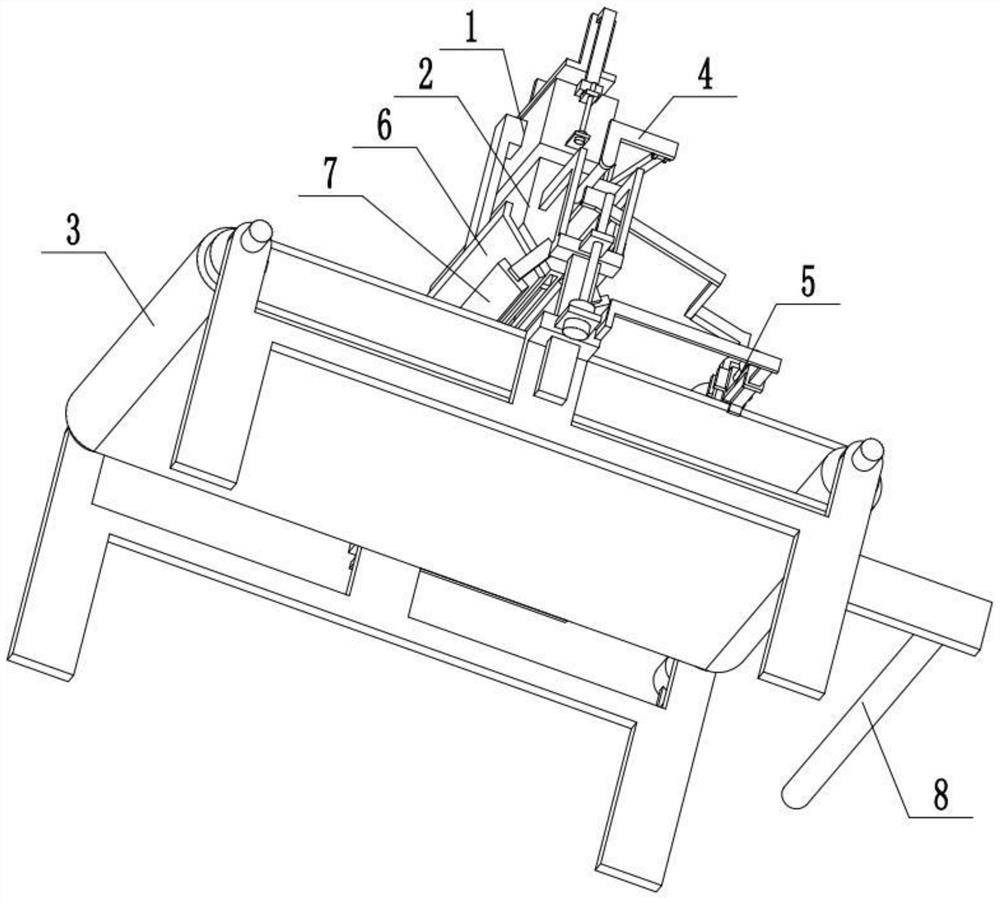

[0033] Combine below Figure 1-9Describe this embodiment, a melt-blown cloth preparation system, including a blanking device 1, a nozzle assembly 2, a receiving device 3, a width adjusting device 4, an edge trimming device 5, a high-temperature airflow generator 6, a cooling airflow generator 7 and a receiving device The cloth roller 8, the described unloading device 1 is fixedly connected to the nozzle assembly 2, the nozzle assembly 2 is connected to the receiving device 3, and the two width adjustment devices 4 are symmetrically arranged at the two ends of the nozzle assembly 2, and the two edge trimmers The device 5 is symmetrically and flexibly connected to both ends of the receiving device 3, and the two width adjusting devices 4 are respectively flexibly connected to the two trimming devices 5, and the two high-temperature airflow generators 6 are symmetrically arranged at both ends of the nozzle assembly 2, and the nozzle assembly 2 Two cooling airflow generators 7 are...

specific Embodiment approach 2

[0035] Combine below Figure 1-9 To illustrate this embodiment, the blanking device 1 includes a melt box 1-1, a blanking pipe 1-2, a fixed plate 1-3, a vertical chute 1-4, a first motor 1-5, a first screw 1-6, L-shaped rod 1-7, sliding sleeve 1-8 and U-shaped pressing plate 1-9; the lower end of the melting material box 1-1 is fixedly connected and communicated with the feeding pipe 1-2, and the feeding pipe 1-2 is connected with the The nozzle assembly 2 is connected, and the two ends of the melt box 1-1 are respectively fixedly connected to a fixed plate 1-3, and the two fixed plates 1-3 are fixedly connected to the nozzle assembly 2, and the fixed plate 1-3 at the left end is provided with The vertical chute 1-4, the two first motors 1-5 are respectively fixedly connected to the two ends of the melting tank 1-1 through the motor frame, and the two first motors 1-5 are respectively connected to a first motor 1-5 through a coupling. The screw rod 1-6, the lower ends of the ...

specific Embodiment approach 3

[0037] Combine below Figure 1-9 To illustrate this embodiment, the nozzle assembly 2 includes a melt blown die head 2-1, a side frame 2-2, a telescopic frame 2-3 and a spinneret hole 2-4; the feeding pipe 1-2 is fixedly connected and connected On the upper end of the melt-blown die head 2-1, the two fixing plates 1-3 are fixedly connected to the melt-blown die head 2-1, and the two ends of the melt-blown die head 2-1 are respectively fixedly connected to a side frame 2- 2. A telescopic frame 2-3 is fixedly connected to the two side frames 2-2, and the two telescopic frames 2-3 are connected with the receiving device 3, and the lower end of the meltblown die head 2-1 is provided with a spinneret hole 2-4, two high-temperature airflow generators 6 are symmetrically arranged at the lower ends of the melt-blown die head 2-1, and two cooling airflow generators 7 are symmetrically arranged at the lower end of the melt-blown die head 2-1; the cooling airflow occurs The device 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com