Double-glass fireproof glass partition wall

A technology of fire-resistant glass and partition wall, which is applied in the direction of fire prevention, walls, building components, etc. It can solve the problems that the supporting structure has no clamping ability, can not give support force and strength, and the keel does not have a double-layer structure, so as to achieve practical equipment. Increased sturdiness and strength, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

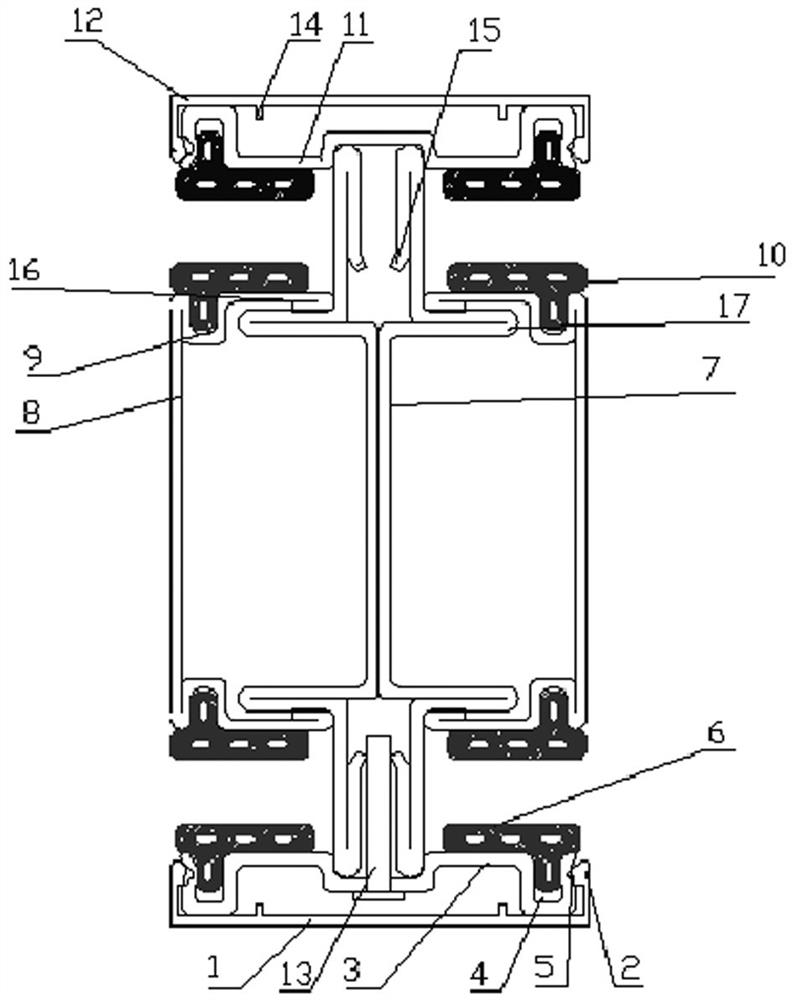

[0021] Such as figure 1 As shown, the double-glazed fire-resistant glass partition wall according to the embodiment of the present invention includes a first decorative panel 1, and both sides of the top of the first decorative panel 1 are provided with convex buttons 2 matched with it. The first decorative panel 1 The top of the panel 1 is provided with a first inner gusset 3 matched with it, the two ends of the first inner gusset 3 are provided with a groove 4 matched with it, and the top of the groove 4 is provided with a The buckle groove 5 matched with the convex buckle 2, the both sides of the top of the first inner gusset 3 are provided with a support frame 6 matched with the groove 4, the middle position of the top of the first inner gusset 3 A keel frame 7 matched with it is provided, and an inner buckle 8 matched with it is provided on both sides of the keel 7 , and auxiliary grooves 9 matched with the inner buckle 8 are symmetrically provided at both ends of the inn...

Embodiment 2

[0025] Such as figure 1 As shown, the middle position of the top end of the first inner gusset 3 is provided with a fixing screw 13 matched with the keel frame 7, and the first veneer 1 and the second veneer 12 are close to the keel frame One side of 7 is symmetrically provided with limit stops 14, and the inner wall at both ends of the keel frame 7 is provided with closing frame 15 matched with it, and the top of the support wing is provided with a turn-back frame matched with the inner buckle 8. Buckle 16, the two sides of the keel frame 7 are symmetrically provided with supporting wings 17 matched with it.

Embodiment 3

[0027] Such as figure 1 As shown, according to the functional requirements, the auxiliary support frame 10 at the top of the keel frame 7 and the support frame 6 at the bottom end of the second inner gusset 11 can not be installed, and the second inner gusset 11 and the top end of the keel frame 7 can be directly installed. Changed from two tempered glass tanks to a single tempered glass tank.

[0028] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0029] In actual application, the tempered glass is put into the tempered glass groove formed by the support frame 6 and the auxiliary support frame 10, and the tempered glass groove is two symmetrically distributed. Layer structure, one-piece bending, when the two are clamped, they can be clamped more tightly. In addition, the closing frame can fac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap