Flange pipeline end measuring method, measuring device and adapter structure

A measurement method and adapter technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problem of no better solution at the end of the pipeline, and achieve the effect of solving the blurred boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

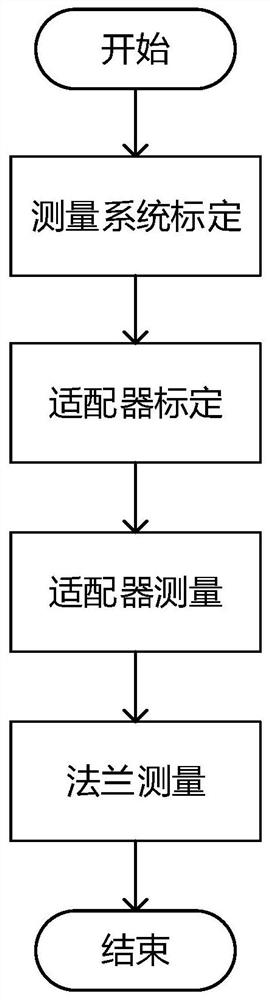

[0033] figure 1 It is a flowchart of a method for measuring a flange pipe end according to an embodiment of the present invention. An embodiment of the present invention provides a method for measuring a flange pipe end, including the following steps:

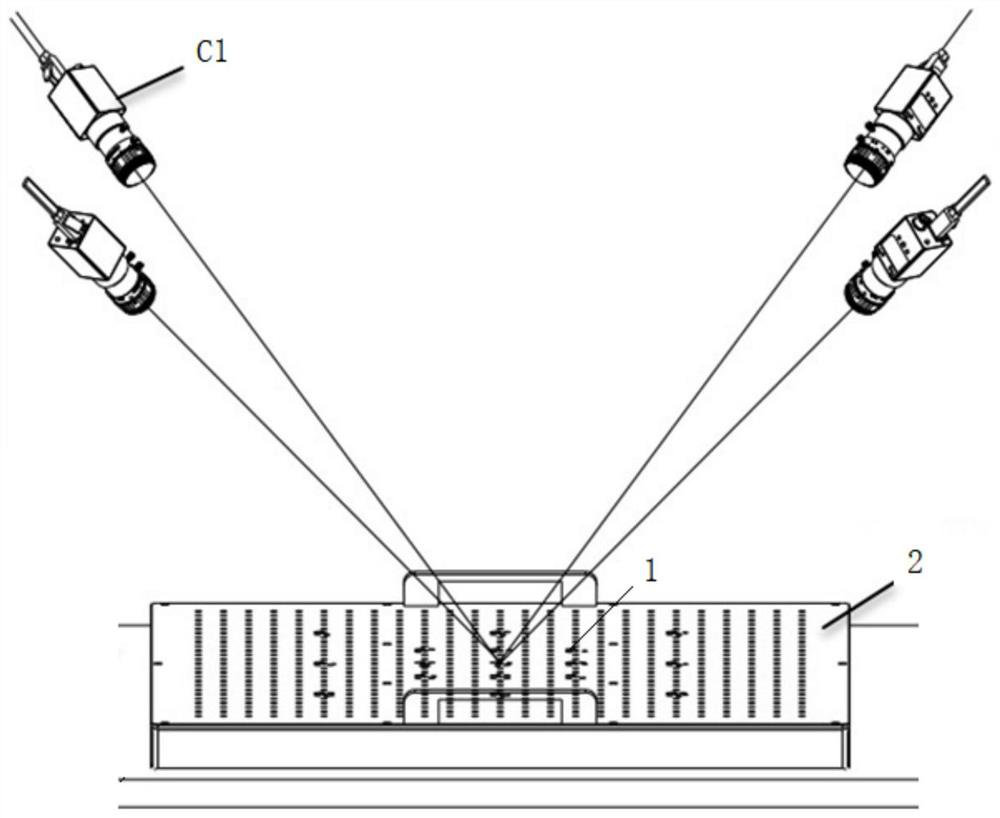

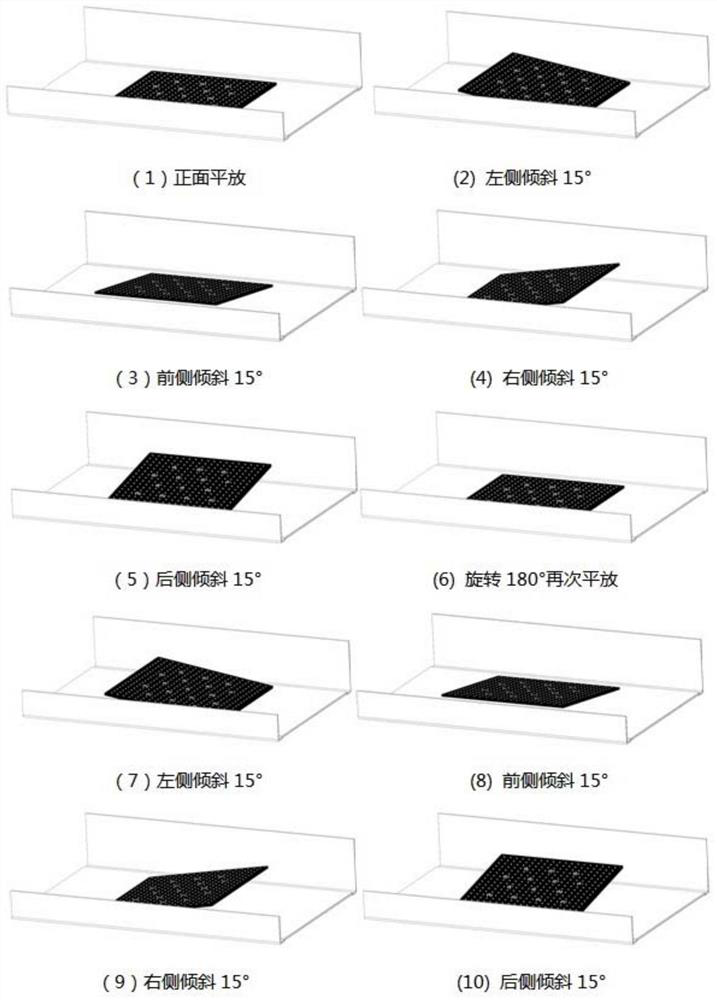

[0034] Step S1, calibrate the multi-camera measurement system (see figure 2 and image 3 );

[0035] Step S2, collect the image of the adapter 3 with the marker point 6 by the multi-camera measurement system (see Figure 4 and Figure 5 ), establish the adapter coordinate system through calculation, and determine the position of the end face and the axis of the adapter 3 in the adapter coordinate system;

[0036] Step S3, the adapter 3 is inserted into the flange hole at the end of the flange pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com