Optical adjusting frame capable of slowing down drifting

A technology of optical adjustment frame and screw rod, applied in the field of optical adjustment frame, can solve the problems of hindering the one-way rigid bonding of screw teeth, high price, processing of wear parts, etc., and achieve the effect of improving the piston effect and improving the position stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

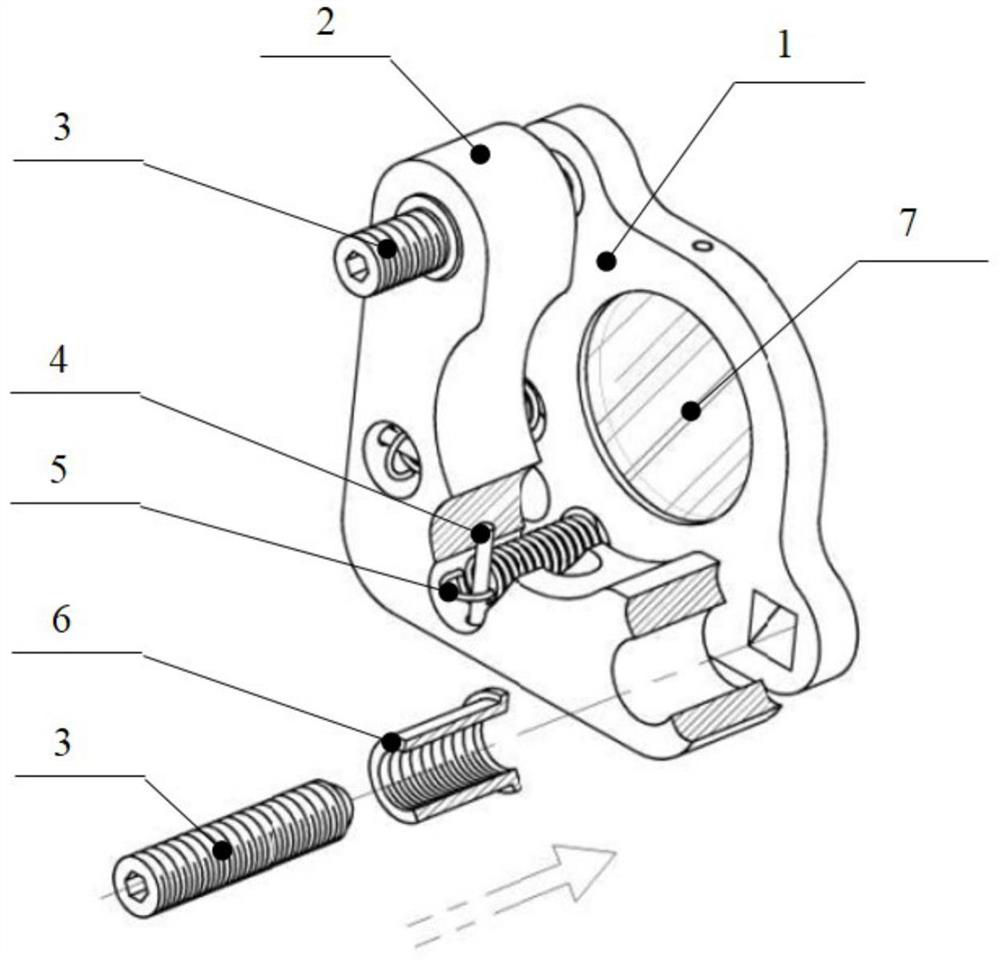

[0022] Such as Figure 4 It is an exploded view of an optical adjustment mount that can slow down drift, including 1 front plate 1, 1 base plate 2, 2 screw rods 12, 2 nuts 13, 2 springs 4, 4 pins and 1 pivot ball 14;

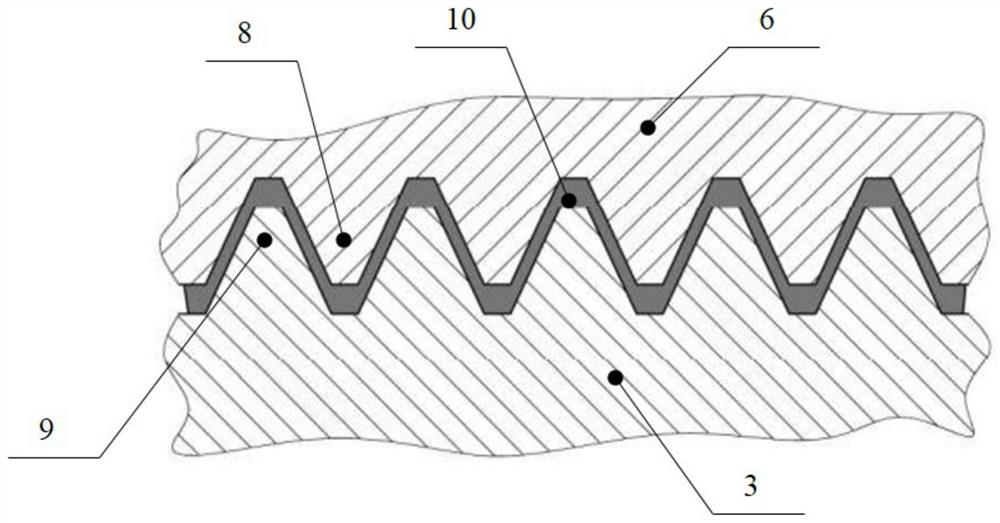

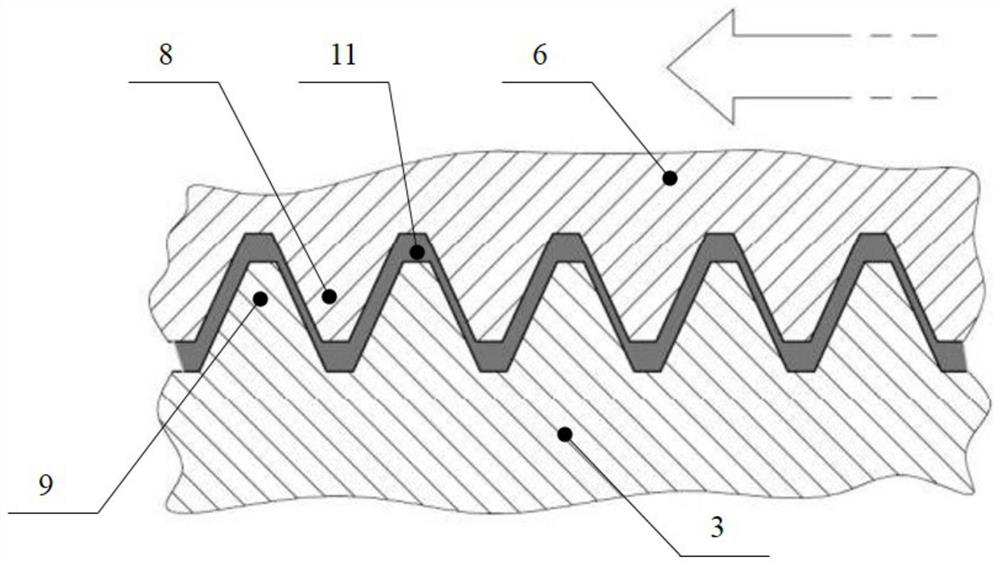

[0023] Such as Figure 5 It is an enlarged view of the specific structure and shape of the screw rod and the nut in the current invention. The cylindrical surface of the screw rod 12 is an external thread 15, which is matched with the internal thread 20 of the nut 13, and the left end surface has an inner hexagonal groove 16, so that it can be inserted into the corresponding Use a hexagonal wrench to adjust the position of the screw, and the end surface on the right side is a spherical tip 17, which realizes point contact with the front plate 1;

[0024] The left side of the nut 13 is a cylindrical surface 18, which is used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com