Galvanometer parameter adjusting method, device and equipment and readable storage medium

A parameter adjustment and parameter technology, applied in image data processing, optics, instruments, etc., can solve the problems of low working performance of galvanometer and inappropriate setting of galvanometer parameters, and achieve the effect of ensuring performance and ensuring a reasonable degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

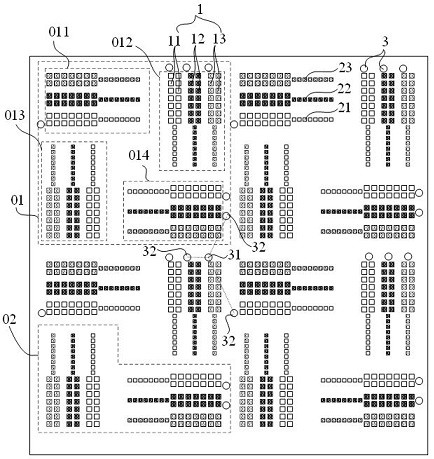

[0058] Such as figure 1 as shown, figure 1 A schematic diagram of the vibration image of the galvanometer. It should be noted that the vibrating image referred to in this application is the image generated by using the three light sources of red, green and blue to emit parallel light beams to mix and enter the vibrating mirror and output to the photosensitive chip from the vibrating mirror. Commonly used test images, which will not be described in detail.

[0059] The vibrating image contains multiple basic vibrating images 01 , and the content of the entire vibrating image is the repetition of the multiple basic vibrating images 01 . The basic vibration image 01 includes four groups of thick vibration lines and thin vibration lines, namely vibration line 1 011, vibration line 2 012, vibration line 3 013 and vibration line 4 014.

[0060] Among them, 1011 kinds of vibrating lines include red vibrating thick line 11, red vibrating thin line 21, green vibrating thick line 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com