High-speed rail station comprehensive energy system scheduling method utilizing train regenerative braking energy

An integrated energy system, regenerative braking technology, applied in the direction of resources, data processing applications, instruments, etc., can solve problems such as energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

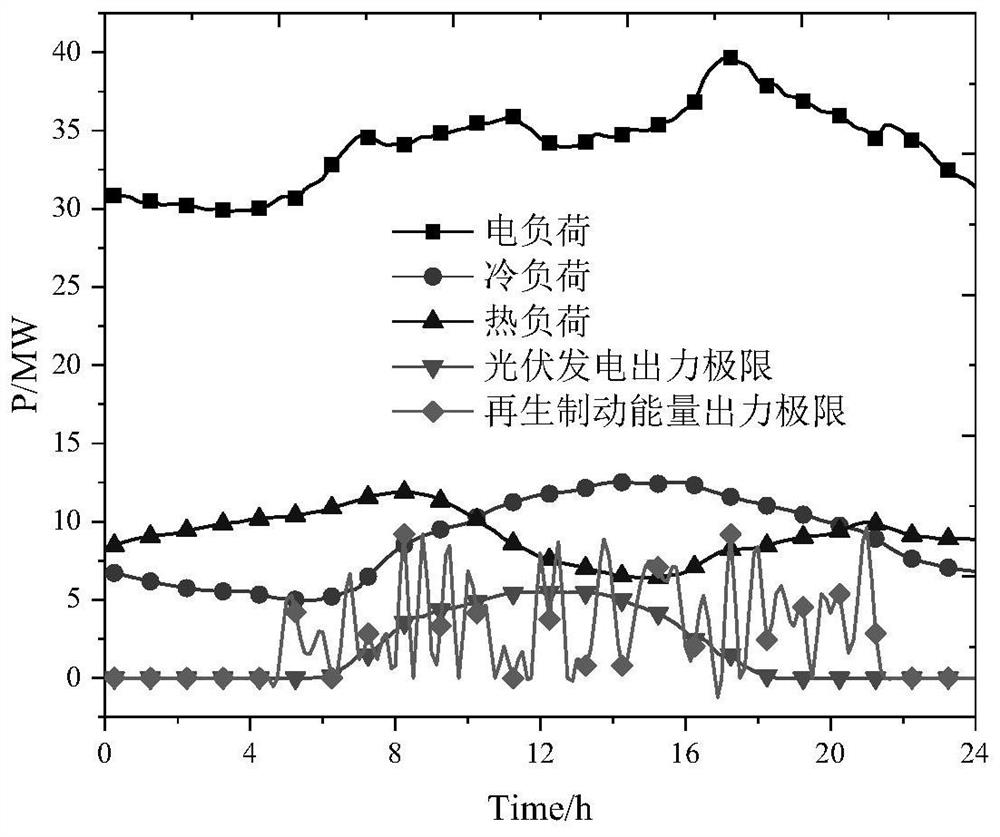

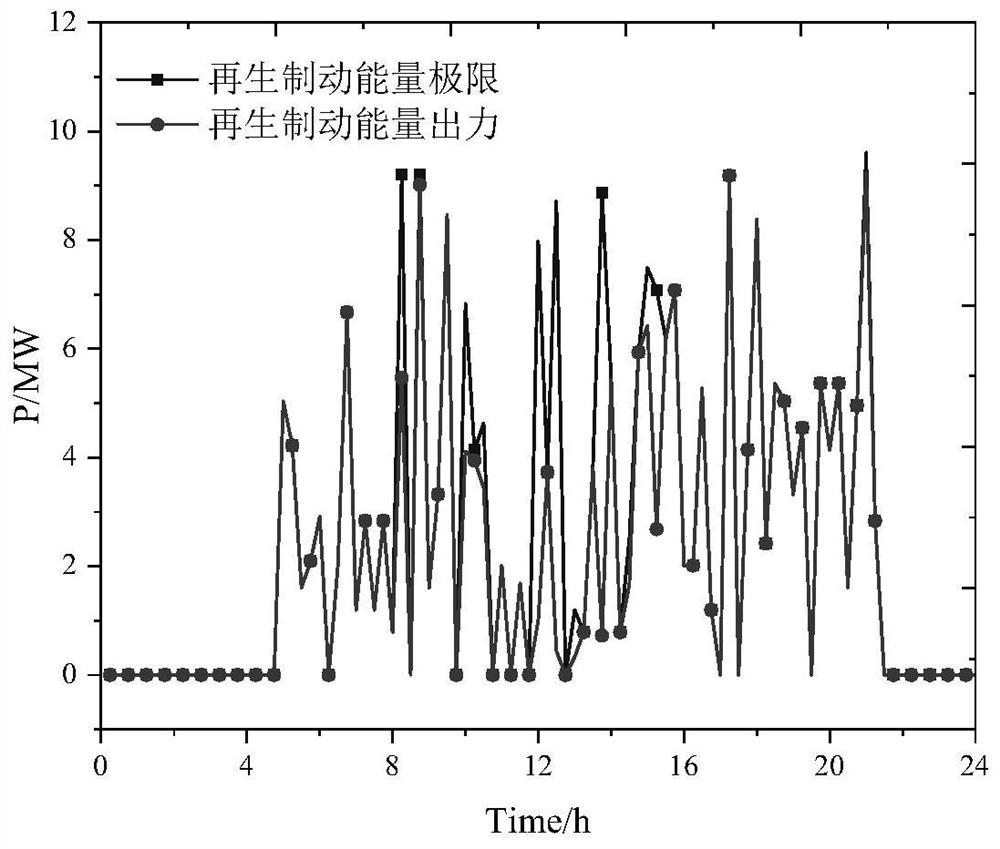

[0071] The high-speed rail station integrated energy system dispatching method using train regenerative braking energy of the present invention promotes the utilization of train regenerative braking energy and the consumption of solar photovoltaic power generation by adding heat storage electric boilers and electric refrigeration units to minimize system operating costs , Minimizing energy consumption and minimizing carbon dioxide emissions are the main goals to solve the optimal solution. The specific implementation steps are as follows:

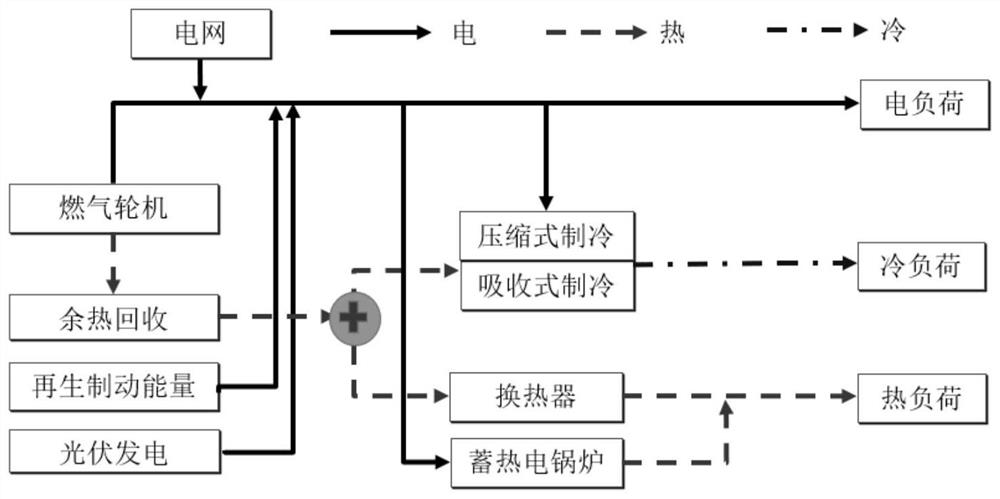

[0072] Step 1: Establish a cold, heat, and electricity integrated energy system that includes train regenerative braking energy, photovoltaic power generation equipment, combined heat and power units, municipal power grids, electric refrigeration units, heat storage electric boilers, and absorption refrigeration units to improve trains The utilization of renewable braking energy and the promotion of the consumption of photovoltaic power generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com