Motor

A technology of motor shaft and motor body, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of easy attenuation of resistance, short service life, easy attenuation of resistance and service life, and achieve long-term resistance maintenance, long service life, The effect of increasing the detent moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

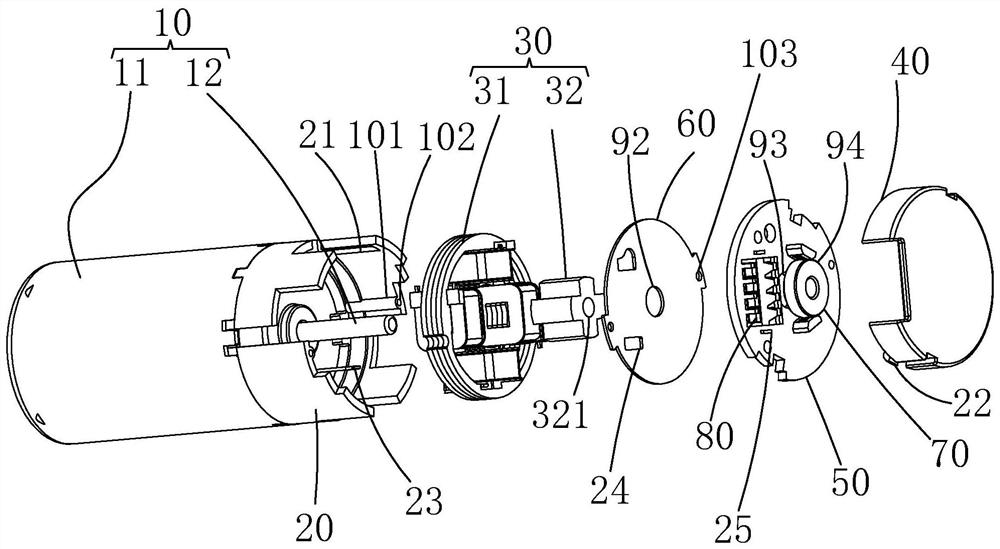

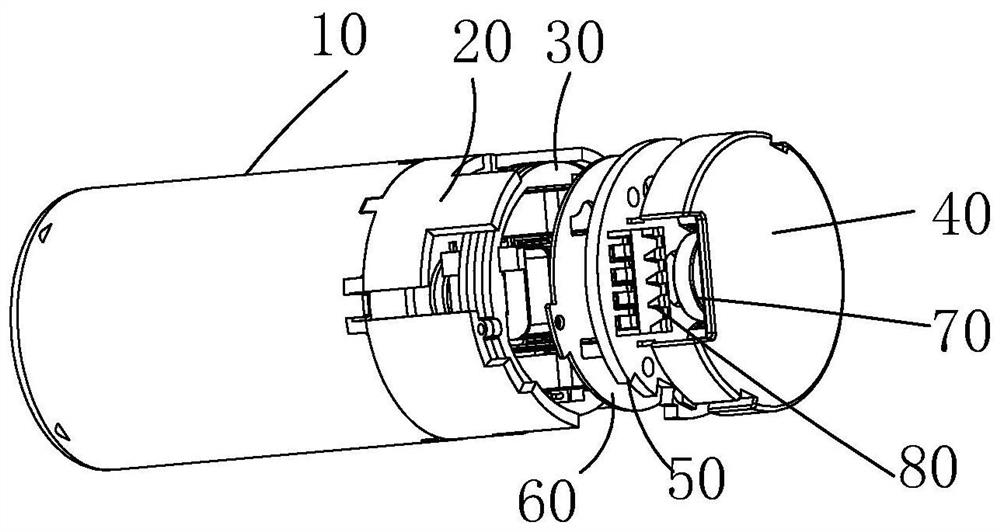

[0035] see Figure 1 to Figure 4 , the present invention provides a motor, including: a motor body 10, a rubber cover 20 and an electromagnetic damper 30;

[0036] The motor body 10 includes: a casing 11 and a motor shaft 12 protruding from one end of the casing 11;

[0037] The rubber cover 20 is mounted on one end of the casing 11;

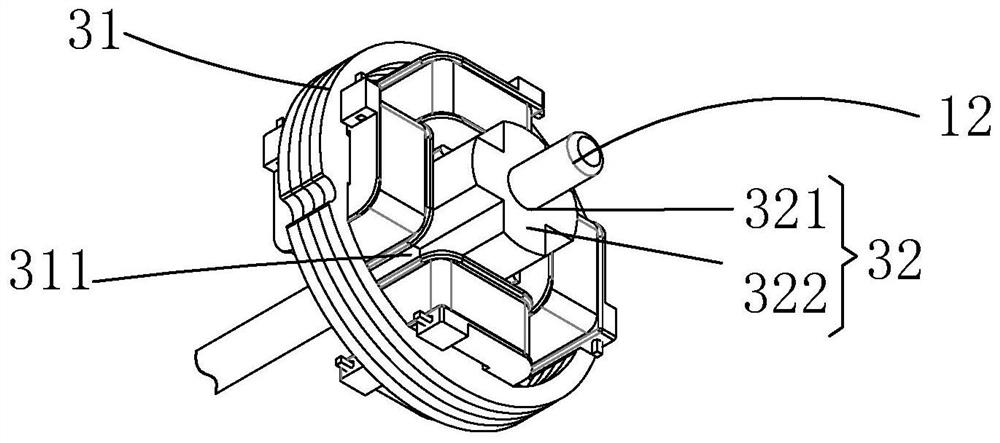

[0038] The electromagnetic damper 30 is installed in the rubber cover 20 and connected with the motor shaft 12;

[0039] The electromagnetic damper 30 can follow the rotation of the motor shaft 12 when the power is off, and can apply resistance to the motor shaft 12 opposite to the rotation direction of the motor shaft 12 when the power is on.

[0040] Wherein, when the electromagnetic damper 30 is energized,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com