A system for increasing the positioning torque of stepper motors

A stepping motor, positioning torque technology, applied in the control system, motor generator control, electrical components, etc., can solve the problems of uncontinuous power supply, poor sealing, inaccurate positioning, etc., to ensure air tightness and reliable operation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

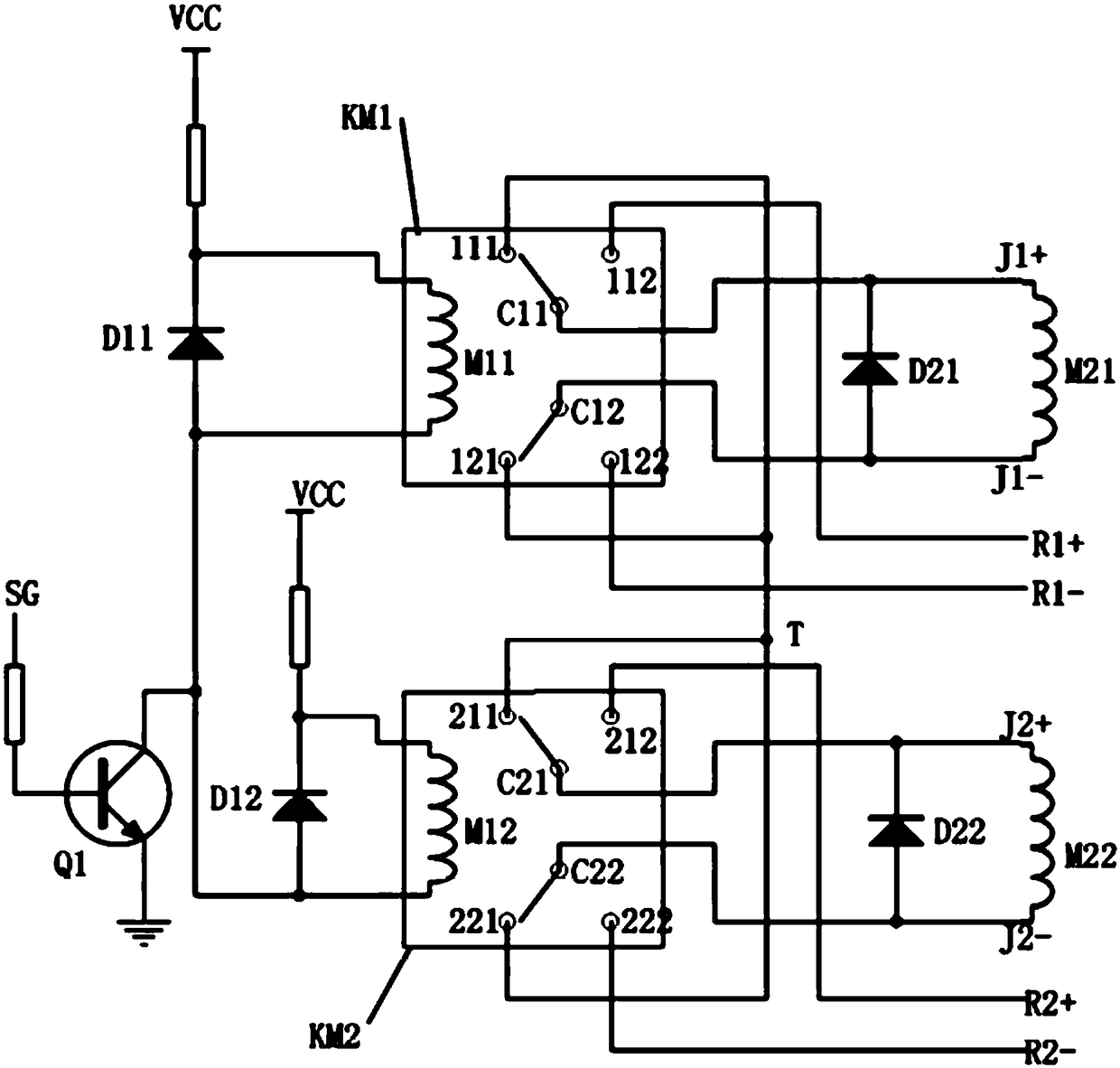

[0016] The following takes a two-phase four-wire stepping motor as an example for description.

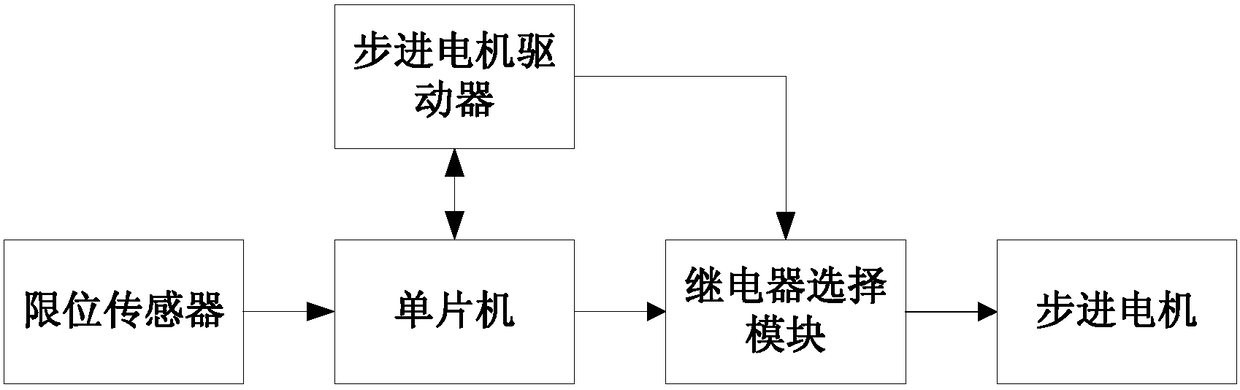

[0017] This embodiment is applied to an intelligent liquid goods vending terminal. One stepper motor driver drives two (not limited to two, but more) stepper motors respectively, and the stepper motor driver drives the stepper motor to drive the puncture docking mechanism to move , Disconnect immediately after the puncture butt joint line is completed. Specifically, as figure 1 As shown, this embodiment includes an ARM Cortex-M series microcontroller, a stepper motor driver, a relay selection module, a stepper motor and a limit sensor.

[0018] Wherein, the limit sensor is arranged on the piercing and docking mechanism, and is used to feedback whether the piercing and docking mechanism has returned to the starting position, and feeds back the signal to the single-chip microcomputer. The single-chip microcomputer controls the stepper motor driver to drive the start and stop, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com