Pneumatic tire

A technology for tires and treads, applied in tire parts, tire treads/tread patterns, vehicle components, etc., can solve problems such as poor results, difficult winter tire performance improvement, not forgetting dry ground, etc., to achieve optimal performance, Good grip level, effect of good grip characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

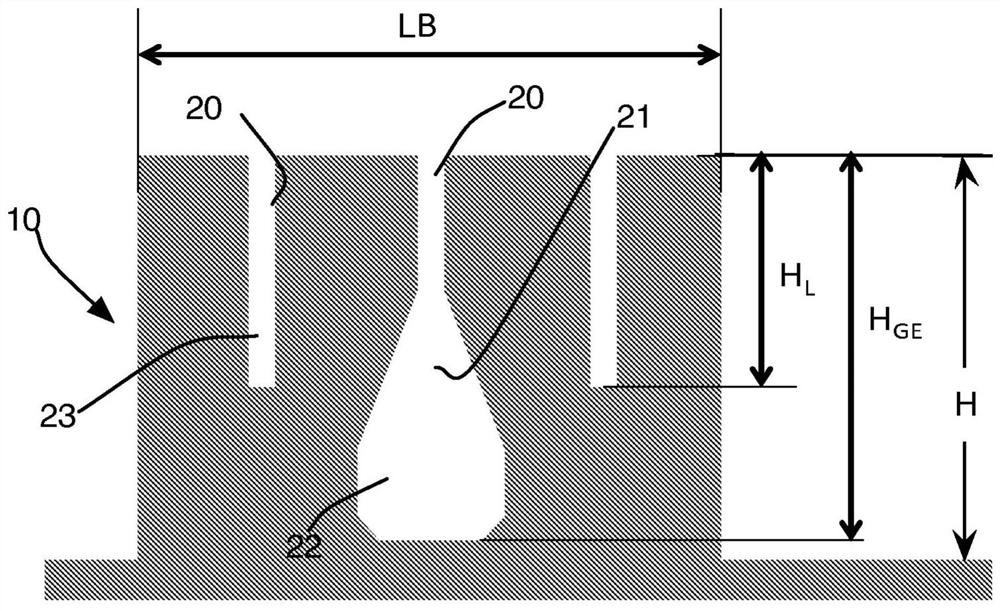

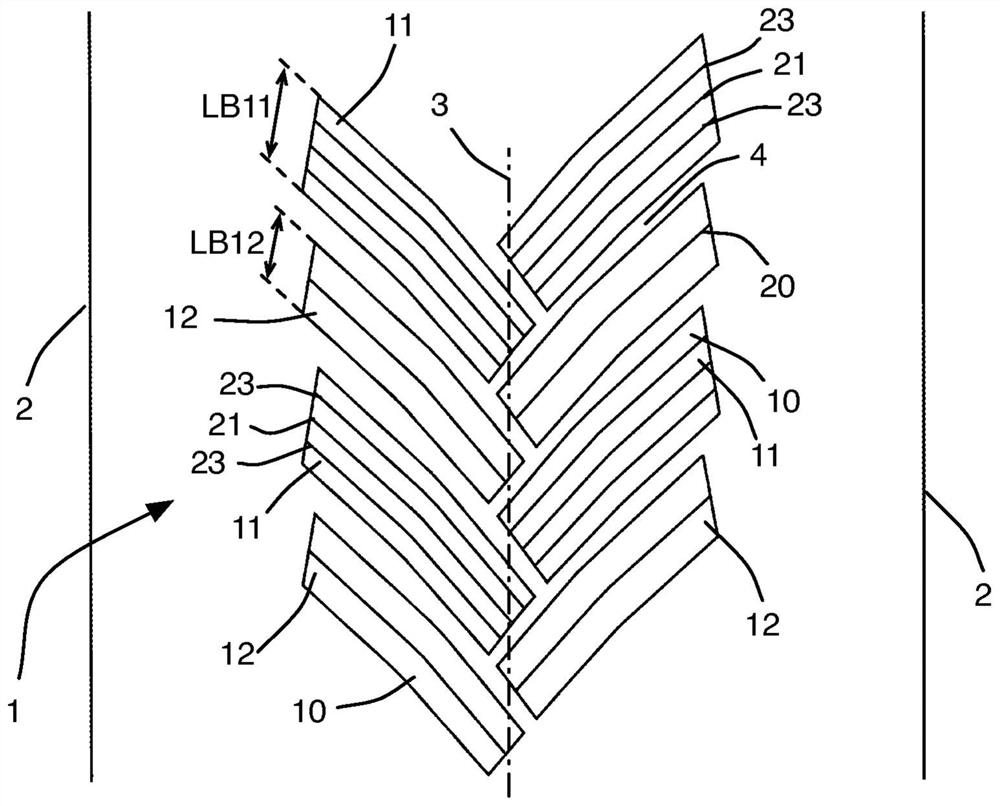

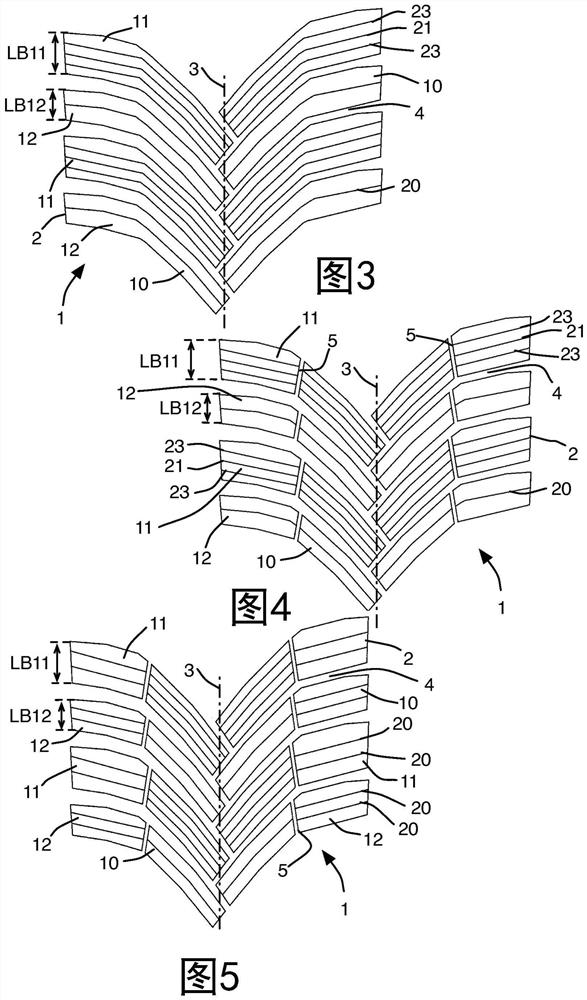

[0032] figure 2 is a schematic diagram showing a first embodiment of a part of the tread 1 of a tire. The tread has two edges 2, a central axis 3 and a plurality of blocks 10 distributed radially over the tread. The blocks 10 are advantageously arranged with a certain inclination or angle of inclination relative to the axis 3 (for example an inclination of between 30° and 60°, and more preferably an inclination of 45°). Hereinafter, this inclination is referred to as the inclination direction of the block.

[0033] In this embodiment, the blocks 10 start at a slightly offset position relative to the edge 2 of the tread. These blocks 10 then continue to extend towards the central axis 3 . The plurality of blocks 10 includes at least two adjacent blocks 11 and 12 . The block 11 has a block width LB11, and the block 12 has a block width LB12. These blocks are each provided with at least one sipe 20, 21, 23 extending along the length of the block.

[0034] From figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com