Method for manufacturing raised sheet, and cleaning sheet

A manufacturing method and technology of raw sheets, applied in the field of cleaning sheets, can solve problems such as difficult to collect garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

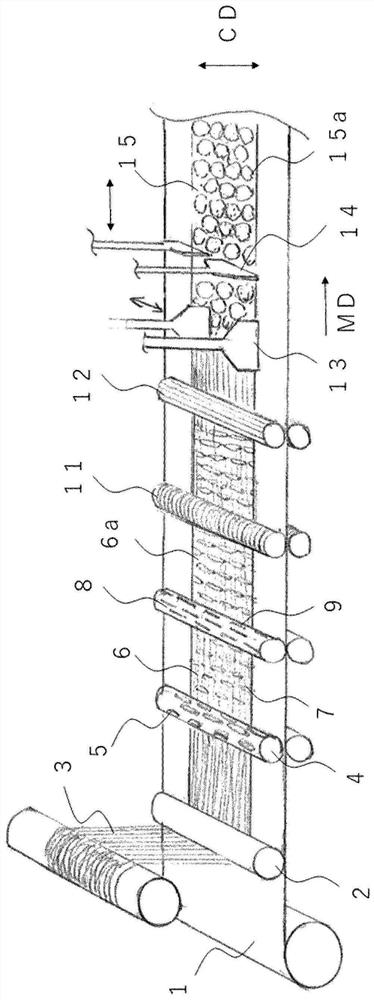

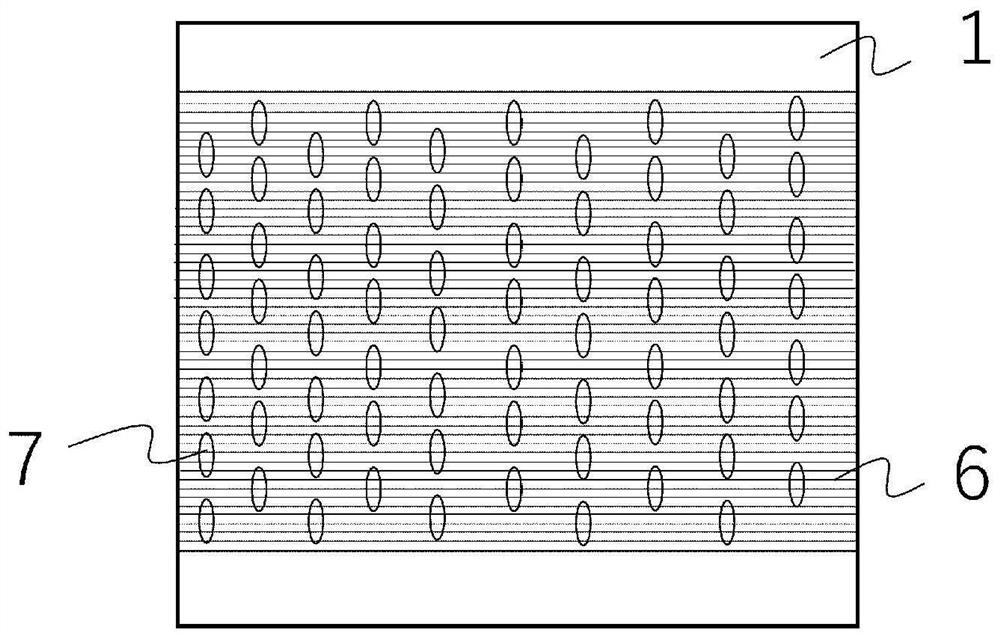

[0037] figure 1 It is a schematic diagram which shows the manufacturing apparatus of the raised sheet which concerns on embodiment of this invention. exist figure 1 , the base material sheet 1 wound into a roll is fed out in the MD (Machine Direction: longitudinal) direction by the feed roller 2 . The base sheet 1 is a sheet made of paper, synthetic resin, nonwoven fabric, etc., but preferably nonwoven fabric. As the nonwoven fabric, a spunlace nonwoven fabric, a spunbonded nonwoven fabric, a thermally bonded nonwoven fabric, an airlaid nonwoven fabric, a point bonded nonwoven fabric, and the like can be used.

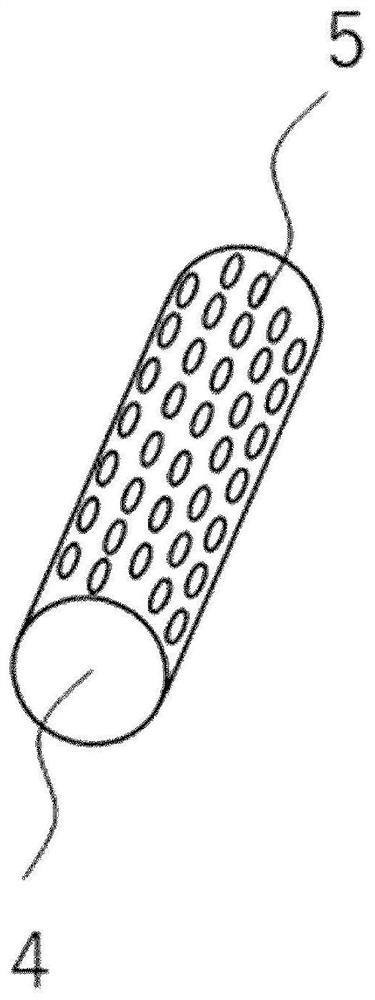

[0038] On the other hand, the fiber aggregate 3 is fed out in the MD direction by the feed roller 2, and in the width direction (CD: Cross Direction, transverse direction) of the base material sheet 1 in a region of a predetermined width including at least the center and the base material sheet. 1 stack. As the fiber aggregate 3, a bundle of fibers in which a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com