Polyamide laminate film and production method for same

A polyamide-based film and polyamide-based technology, applied in the direction of chemical instruments and methods, layered products, flat products, etc., can solve the problem of uniformity of stretched film thickness, unsatisfactory dimensional stability, and metal foil breakage , low productivity and other problems, to achieve excellent balance of stress, prevent metal foil from breaking, and excellent uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

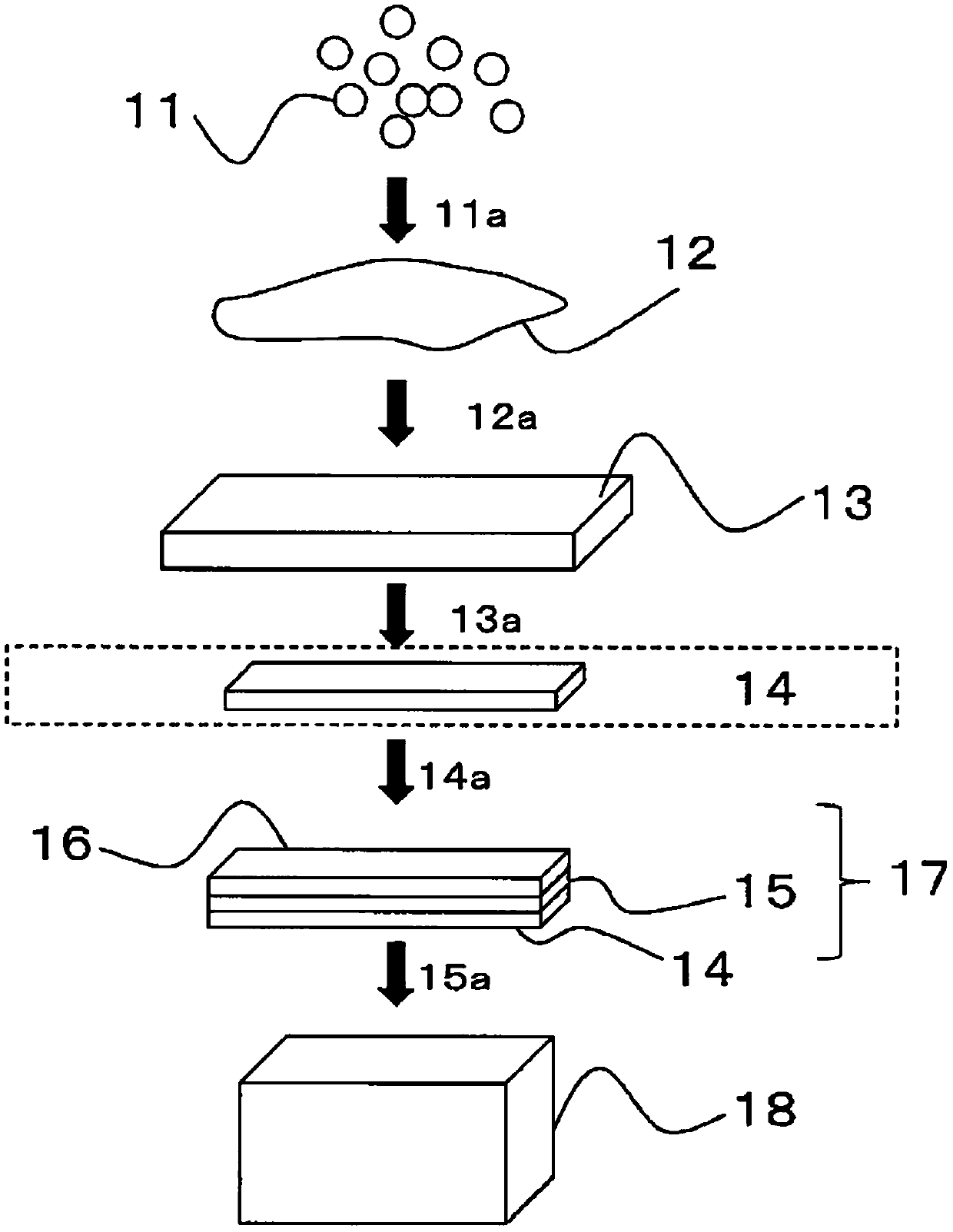

[0166] The preparation itself of the melt-kneaded product may be carried out according to a known method. For example, a raw material containing a polyamide resin is put into an extruder equipped with a heating device, heated to a predetermined temperature and melted, the melted kneaded product is extruded through a T die, and cooled by a casting drum or the like. By curing, an unstretched sheet that is a sheet-shaped molded product can be obtained.

[0167] The average thickness of the unstretched sheet at this time is not particularly limited, but is usually about 15 to 250 μm, particularly preferably 50 to 235 μm. By setting it in such a range, a stretching process can be implemented more efficiently.

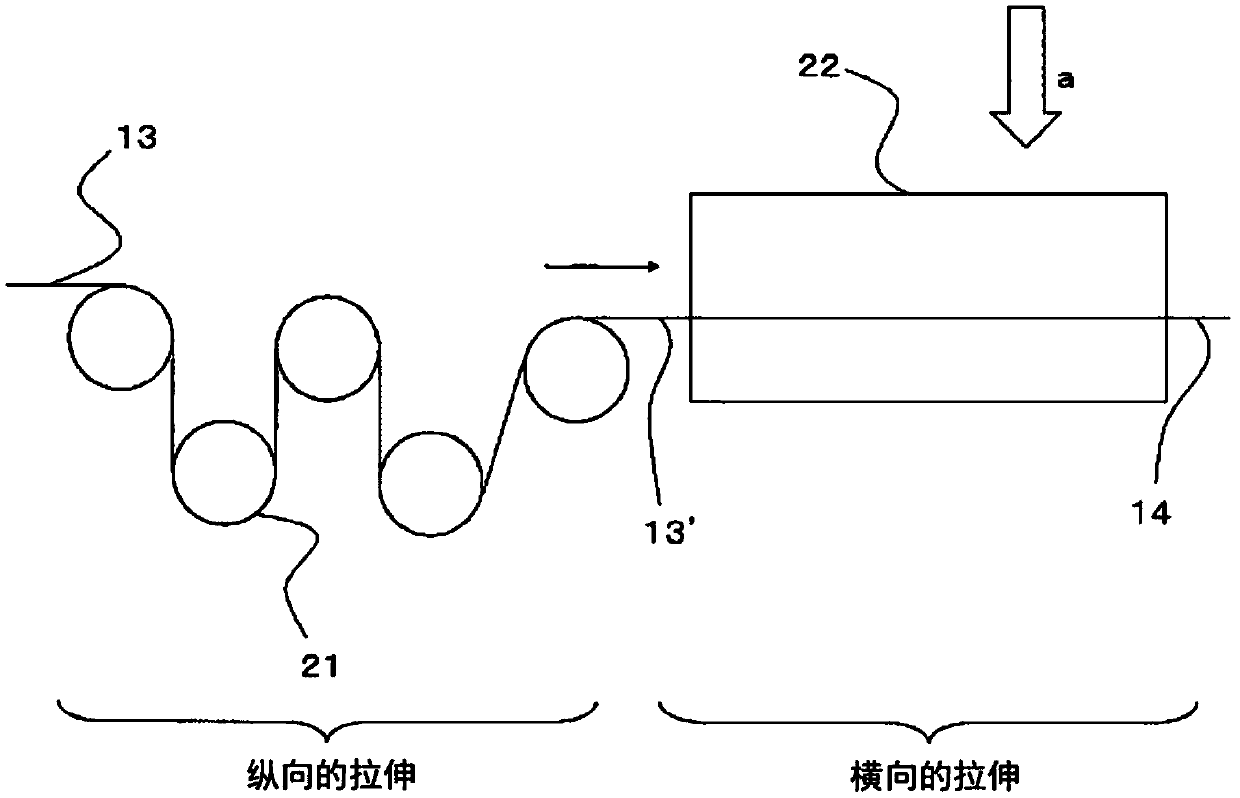

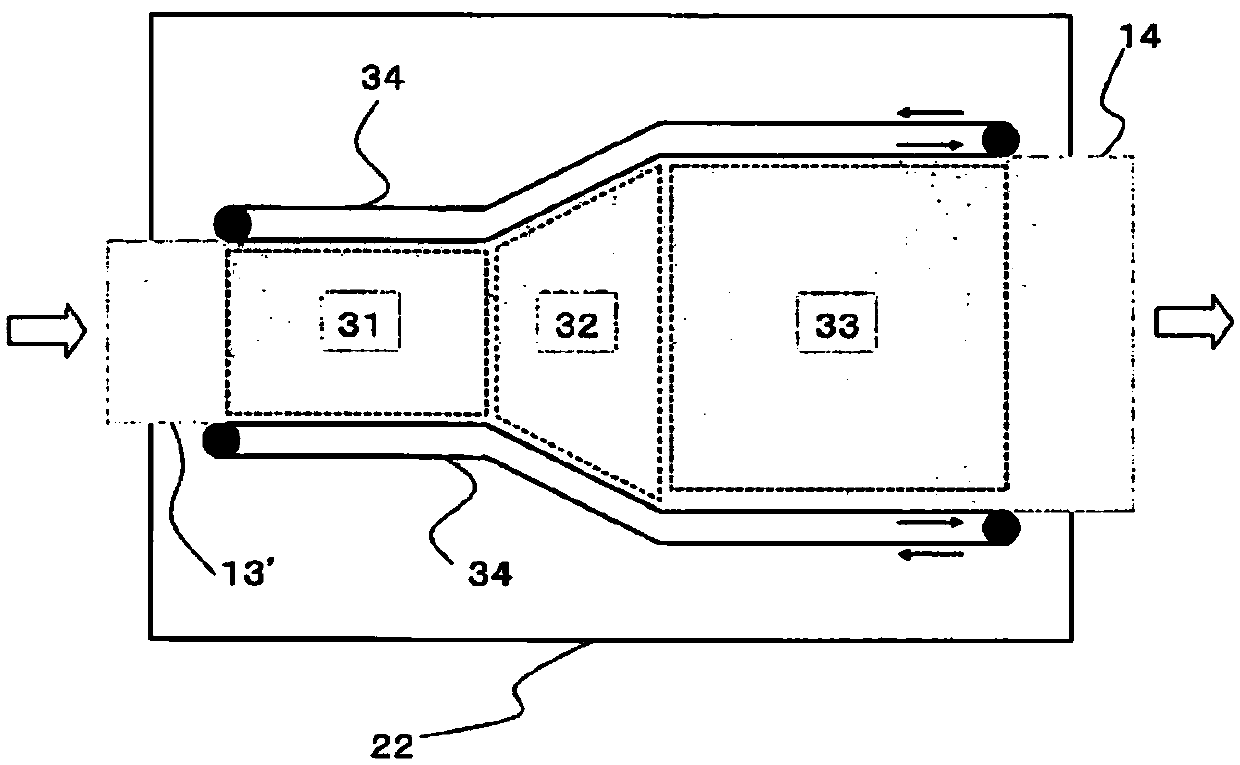

[0168] stretching process

[0169] In the stretching step, the unstretched sheet is sequentially or simultaneously biaxially stretched in MD and TD to obtain a stretched film.

[0170] As described above, a stretched film obtained by sequential biaxial stretching includ...

Embodiment

[0230] Examples and comparative examples are shown below to more specifically describe the characteristics of the present invention. However, the scope of the present invention is not limited by the examples. In addition, the measurement method and evaluation method of various characteristic values of the polyamide-type film, polyamide-type laminated film, and laminated body obtained in the Example and the comparative example were performed as follows.

[0231] (1) Composition of copolyester resin

[0232] 1H-NMR measurement was performed using an NMR measurement apparatus (JNM-LA400 type manufactured by JEOL Ltd.), and the composition of each copolymerization component was calculated|required. In addition, deuterated trifluoroacetic acid was used as a measurement solvent.

[0233] (2) Number average molecular weight of copolyester resin

[0234] Using gel permeation chromatography (GPC), the polystyrene-equivalent number average molecular weight was measured under the fo...

preparation example 1

[0271] 83g (50 mol%) of terephthalic acid, 83g (50 mol%) of isophthalic acid, 23g (37 mol%) of ethylene glycol, 66g (63 mol%) of neopentyl glycol, 1,4-cyclohexane 36 g (25 mol%) of alkane dimethanol, 100 g (10 mol %) of polytetramethylene glycol, and 0.1 g of tetrabutyl titanate as a polymerization catalyst were charged into the reactor, and the system was replaced with nitrogen. Then, stirring these raw materials at 1000 rpm, the reactor was heated at 245° C. to melt them. The esterification reaction was carried out for 3 hours after the temperature in the reactor reached 245°C. After 3 hours, the temperature in the system was set to 240° C., and the pressure in the system was reduced. In the system to achieve high vacuum (pressure: 0.1 ~ 10 -5 After Pa), the polymerization reaction was carried out for another 3 hours to obtain the copolyester resin (A).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com