Fixing bracket piece for slit acoustic panel, fixing structure and mounting method

A technology for fixing structures and sound-absorbing panels, applied in sound insulation, building components, building structures, etc., can solve the problems of low construction quality, unfavorable slat installation, unfavorable appearance, etc., to improve construction efficiency, construction quality, and fixation effect. Excellent and conducive to standardized construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

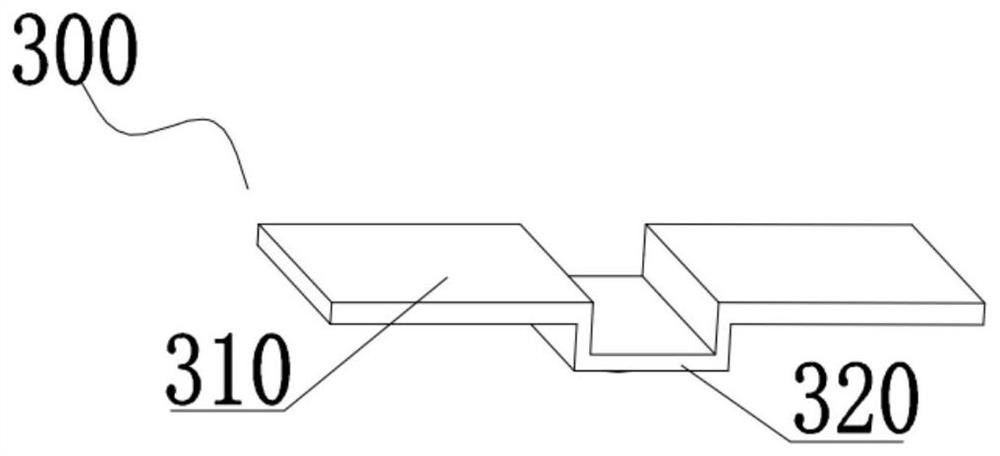

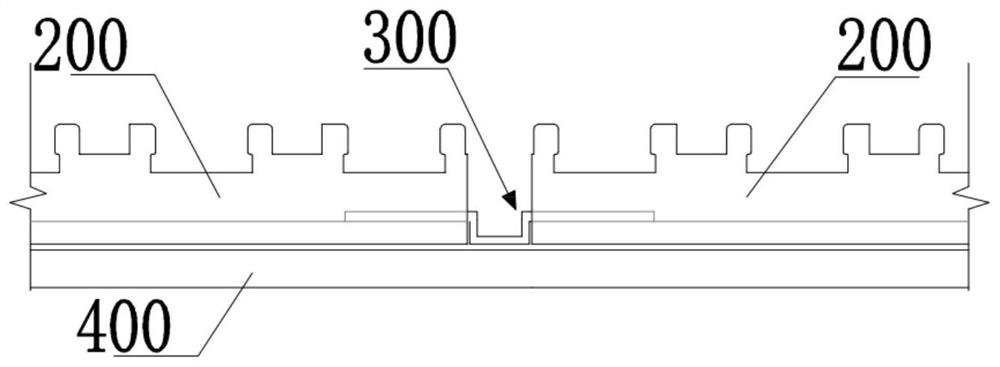

[0058] Such as Figure 1-2 As shown, a fixed code piece for a slit sound-absorbing panel, including:

[0059] The clamping plate 310 for positioning the slit sound-absorbing panel 500 and the fixing part 320 for fixing the fixing code part 300 to the structural keel 400 .

[0060] The clamping plate 310 is disposed at both ends of the fixing part 320 , and the fixing part 320 is a protruding structure on the fixing code part 300 . The clamping plate 310 is a straight plate, so that the overall processing difficulty of the fixed code member 300 is reduced. The fixing method of the fixing part 320 on the structural keel 400 is welding. If the protruding height value of the fixing part 320 is less than or equal to the plate thickness of the slat keel 200 on the slit sound-absorbing panel 500, the clamping plate 310 can directly fasten the slat keel 200; When the thickness of the slat keel 200 on the sound-absorbing panel 500 is seamed, another cushion layer (such as a rubber s...

Embodiment 2

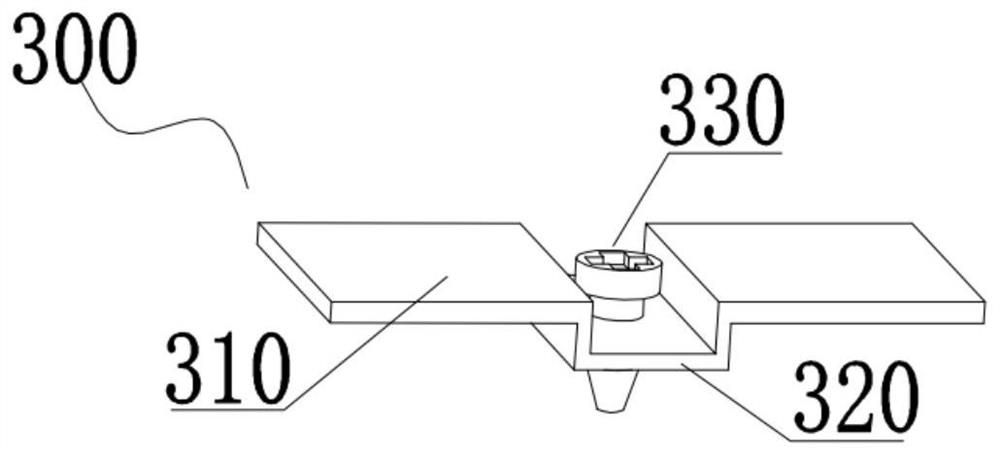

[0064] A fixed code for a slit sound-absorbing panel, such as Figure 3-4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the fixing code member 300 further includes fixing nails 330 , and the fixing part 320 is connected to the structural keel 400 through the fixing nails 330 . The fixing part 320 is nailed to the structural keel 400 by using the fixing nail 330 , so that the entire fixing code part 300 is fixed to the structural keel 400 . The method of nailing has the advantages of simplicity, stability and reliability. The fixing nail 330 is a screw.

Embodiment 3

[0066] A fixed code for a slit sound-absorbing panel, such as Figure 5-6 As shown, Embodiment 3 is based on Embodiment 2, and the fixing nail 330 is selected as a countersunk head self-tapping screw. A chamfer structure 321 matching the countersunk head self-tapping screw is provided at the joint between the clamping plate 310 and the fixing portion 320 . After the countersunk head self-tapping screw is screwed into the fixing part 320 , both sides of the countersunk head self-tapping screw abut against the chamfered structure 321 , so that the overall strength of the fixed code member 300 is increased, and the structural stability is increased. The installer can simply screw the countersunk head self-tapping screw into the fixing part 320 , so as to nail the fixing part 300 to the structural keel 400 , and it can be disassembled and installed repeatedly. Such as Figure 7-10 As shown, the countersunk-head self-tapping screws nail the fixing piece 300 to the structural keel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com