Novel pressing type valve element

A push-type, valve core technology, applied in the field of new push-type valve core, new type of push-type valve core with adjustable flow, can solve the problem of inability to adjust the flow, achieve convenient valve opening and closing operation, meet the needs of flow regulation, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

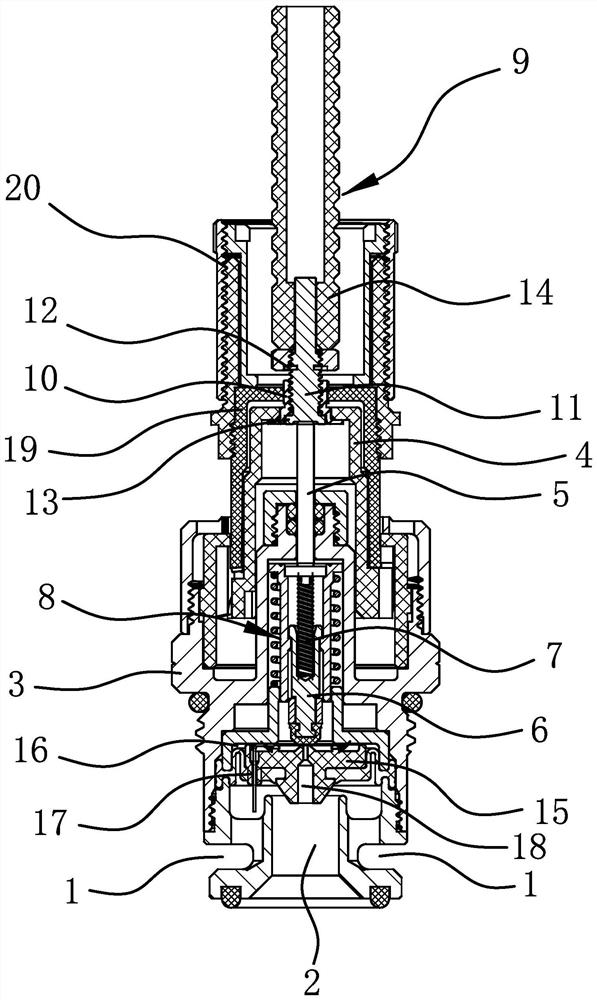

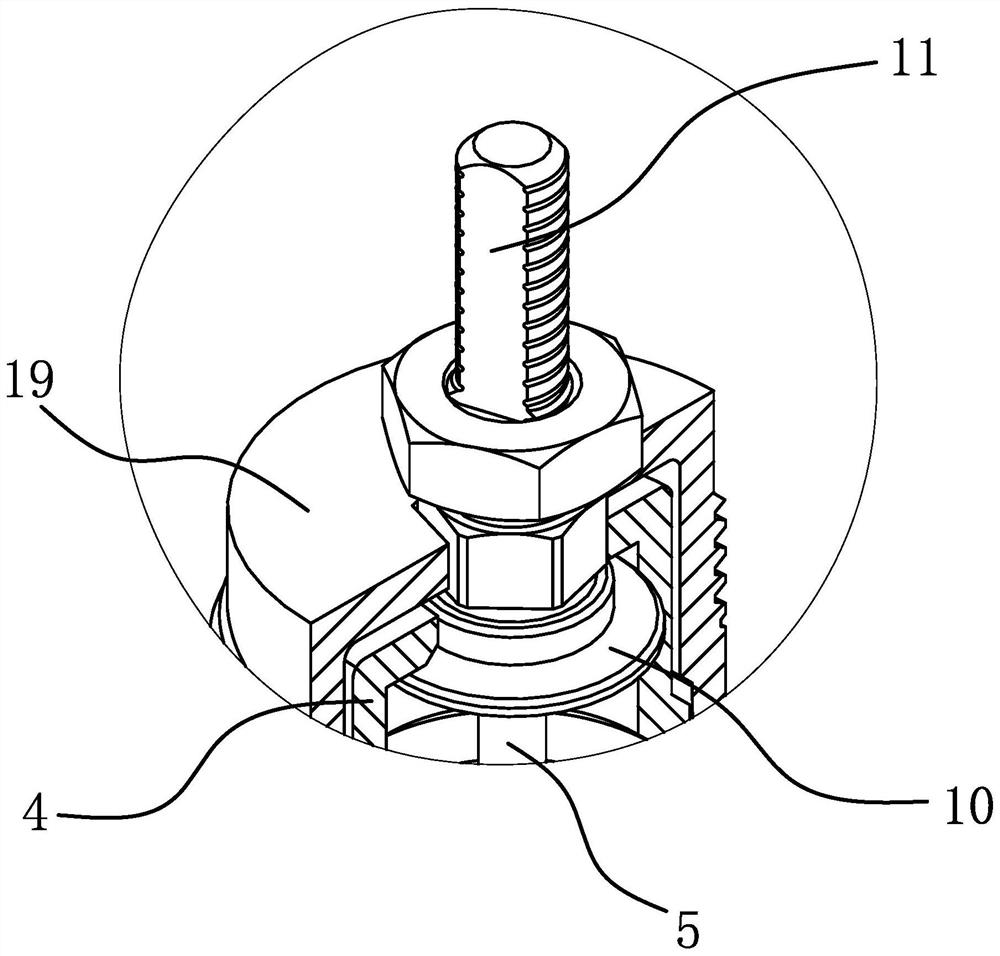

[0022] Such as figure 1 and figure 2 As shown, the push-type spool of the present invention includes a spool shell 3 with a water inlet 1 and a water outlet 2 at the lower part, and the water inlet 1 and the water outlet 2 are communicated through a water passage. The upper part of the spool case 3 is provided with a sliding claw cover 4 and a telescopic mechanism that can make the sliding claw cover 4 switch between the high position and the low position. The sealing core 6 below the pressing rod 5 and the sealing spring 7 arranged between the pressing rod 5 and the sealing core 6 . The two ends of the sealing spring 7 act on the pressure rod 5 and the sealing core 6 respectively, the pressure rod 5 can move to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com