High-current wire spring contact piece module structure and high-current terminal connection structure

A modular structure and contact piece technology, applied in the direction of fixed/insulated contact components, connections, contact parts, etc., can solve the problems of small application range, long development cycle, inflexible use, etc., achieve safe and reliable application range, and low mold cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

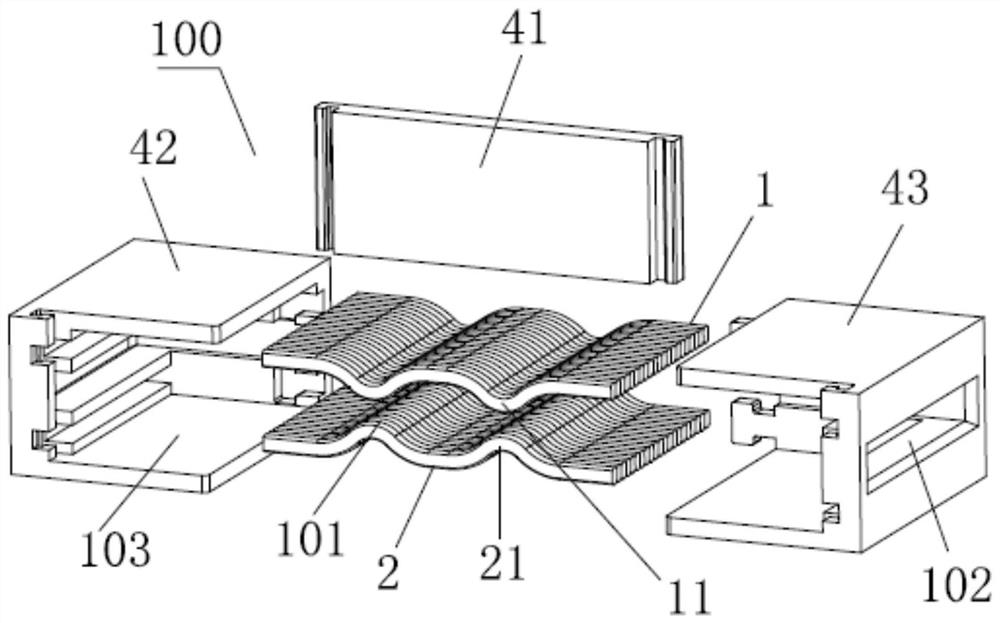

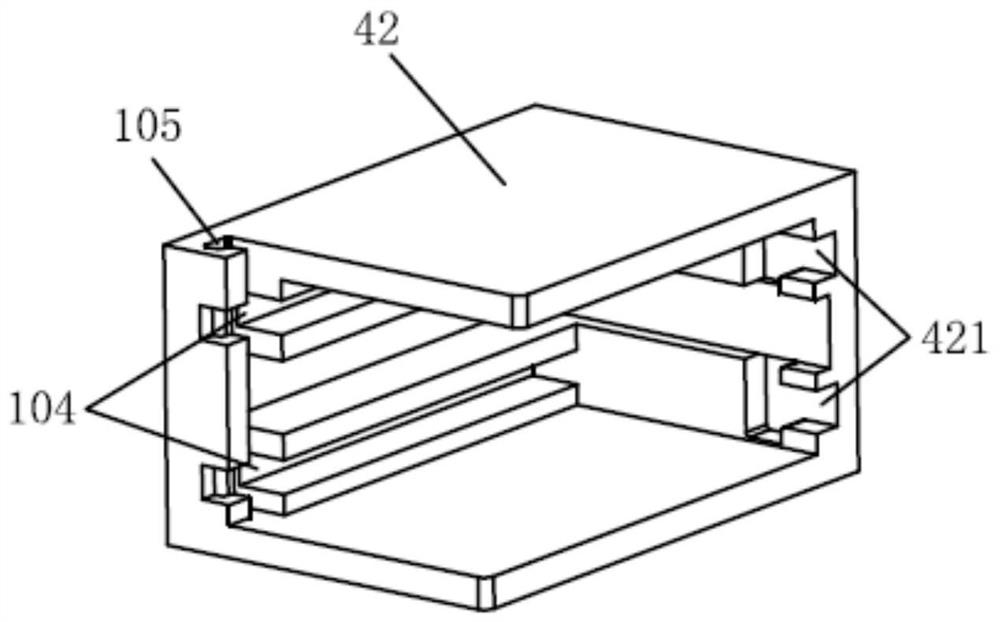

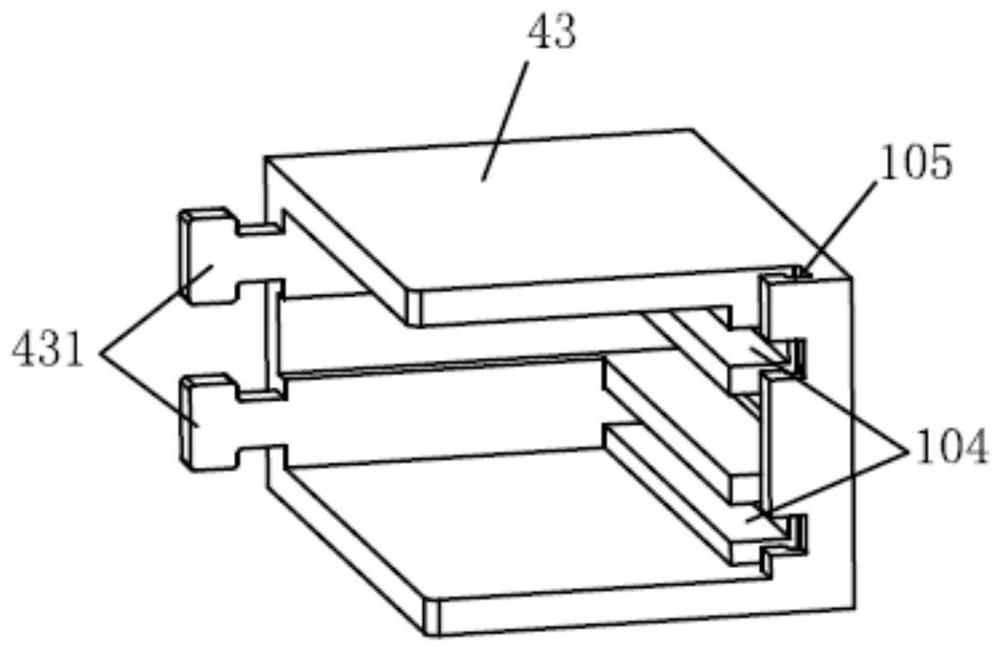

[0029] Such as Figure 1 to Figure 5 As shown, the high-current wire spring contact piece module structure 100 shown in this embodiment includes a sheath and a first wire spring group 1 and a second wire spring group that are clamped in the sheath and arranged in an up-and-down interval. 2. The side of the first wire spring group 1 facing the second wire spring group 2 is provided with two convex first contact points 11 spaced apart, which are used as the contact points of the two terminals respectively, and the second wire spring group 2 faces the first wire Two second contact points 21 corresponding to the upper and lower first contact points 11 are protrudingly provided on one surface of the spring set 1, and a gap 101 is provided between the first contact point 11 and the second contact point 21. There are insertion ports 102 at both ends of the corresponding gaps. The insertion ports are used for the insertion of the terminals. The terminals at both ends are inserted into t...

Embodiment 2

[0039] Such as Figure 1 to Figure 7 As shown, the high-current terminal connection structure shown in this embodiment includes the high-current wire spring contact piece module structure 100 as described in Embodiment 1, and further includes first insertion openings 102 respectively inserted into the left and right ends of the sheath. The inner ends of the terminal 5 and the second terminal 6, the first terminal 5 and the second terminal 6 are inserted into the gap 101 between the first contact point and the second contact point on the corresponding side, that is, the first terminal 5 is inserted into the left side In the gap 101 between the first contact point and the second contact point, the second terminal 6 is inserted into the gap 101 between the first contact point and the second contact point on the right side. In actual use, the first terminal 5 and The thickness of the second terminal 6 is slightly larger than the width of the gap 101, so that the upper and lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com