Deflection coil for ultra large deflection float CRT

A deflecting coil and picture tube technology, applied in the direction of electrode device and related components, can solve problems such as difficulty and difficulty in small light spots, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

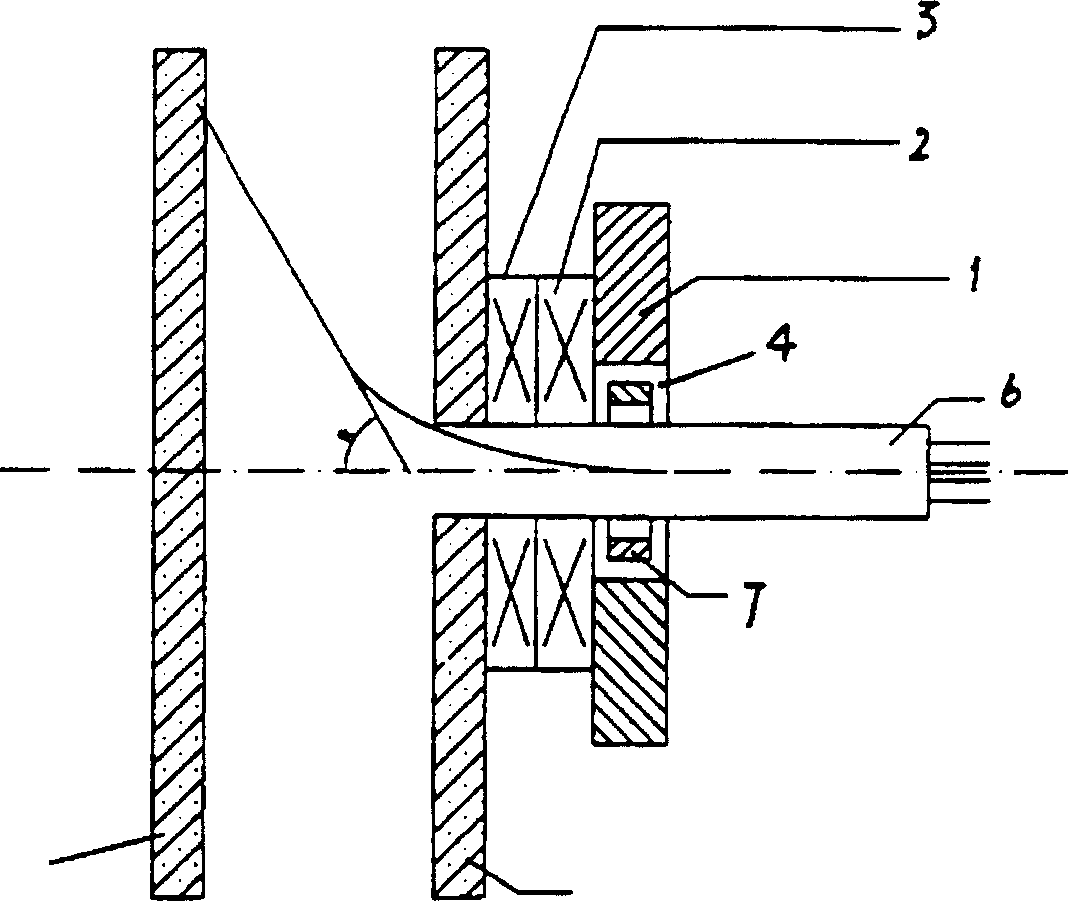

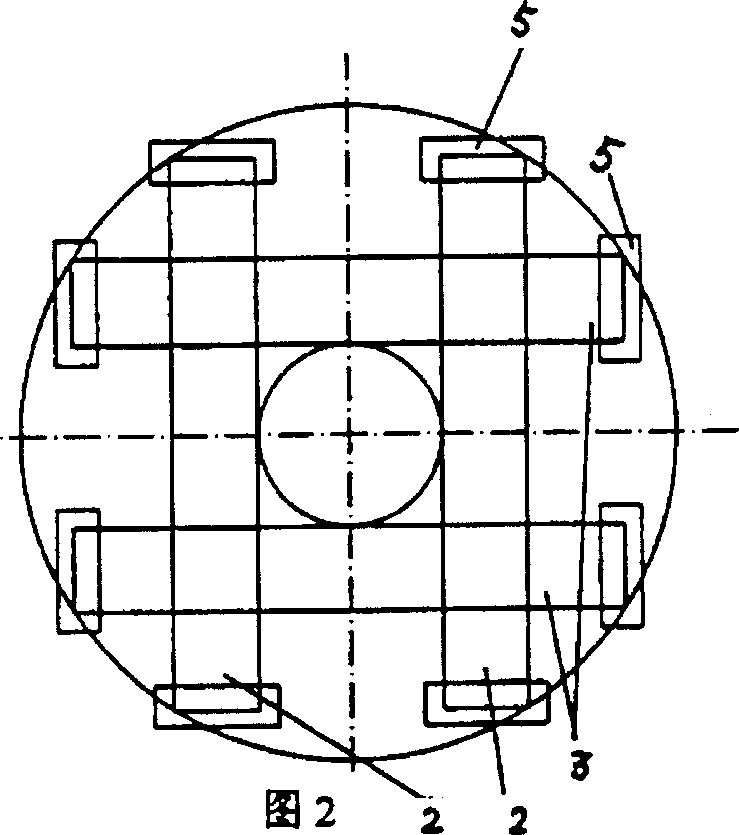

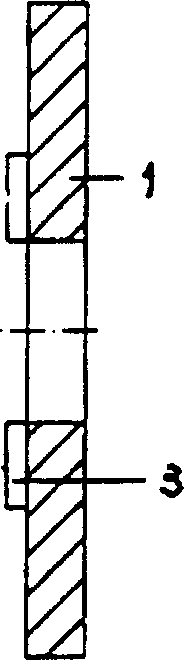

[0018] like figure 1 , Figure 2 and image 3 As shown, the present invention mainly includes: a ferrite core 1, a frame deflection coil 2 and a line deflection coil 3. On a flat circular or rectangular ferrite core 1, a pair of The plane rectangular frame deflection coil 2 and a pair of plane rectangular line deflection coils 3 form a basic plane deflection coil pattern. The diameter of the central hole 4 of the ferrite core 1 is determined by the diameter of the electron gun 6 . A rectangular correction coil 5 is added to the short arm of each rectangular coil to correct the pincushion distortion of the picture, or a magnetic field shielding plate is used to eliminate the pincushion distortion. The deflection angle R has focusing characteristics from 0° to 80°.

[0019] like figure 1 , Figure 4 and Figure 5 As shown, a small circular or square ferrite core 8 is placed in the central hole 4 of the circular ferrite core 1, and a pair of frame and row pre-deflection coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com