Magnetic stirrer

A magnetic stirrer and controller technology, applied in chemical instruments and methods, dissolving, mixing machines, etc., can solve problems such as high cost, easy oil leakage noise of reducer, and inability to meet clean and hygienic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

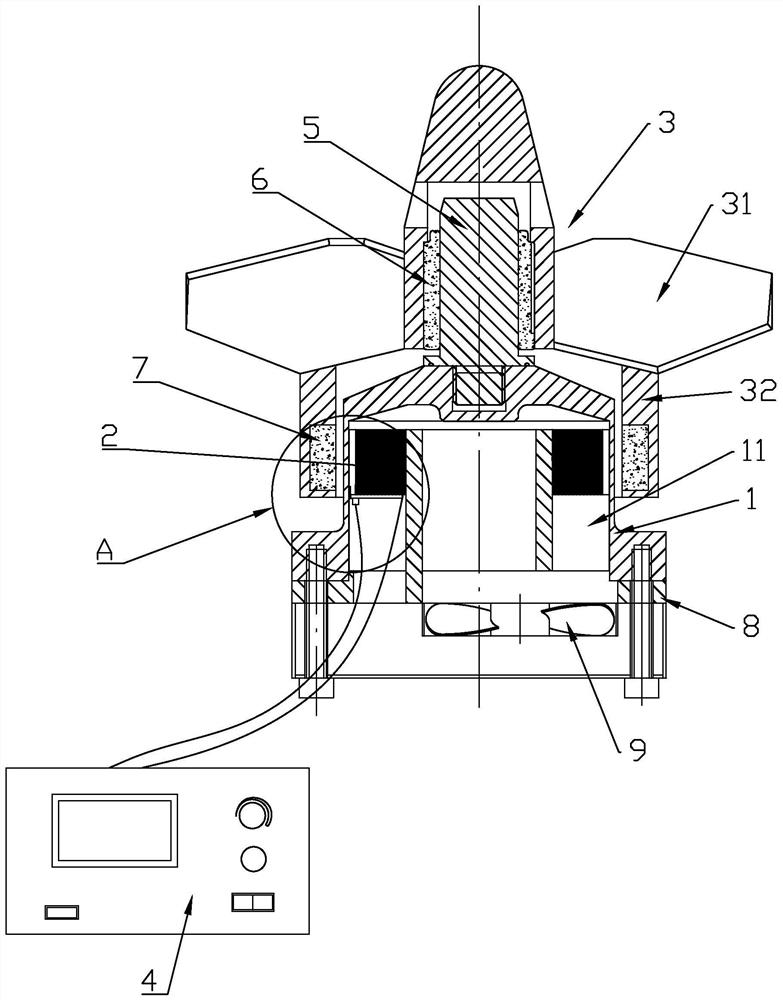

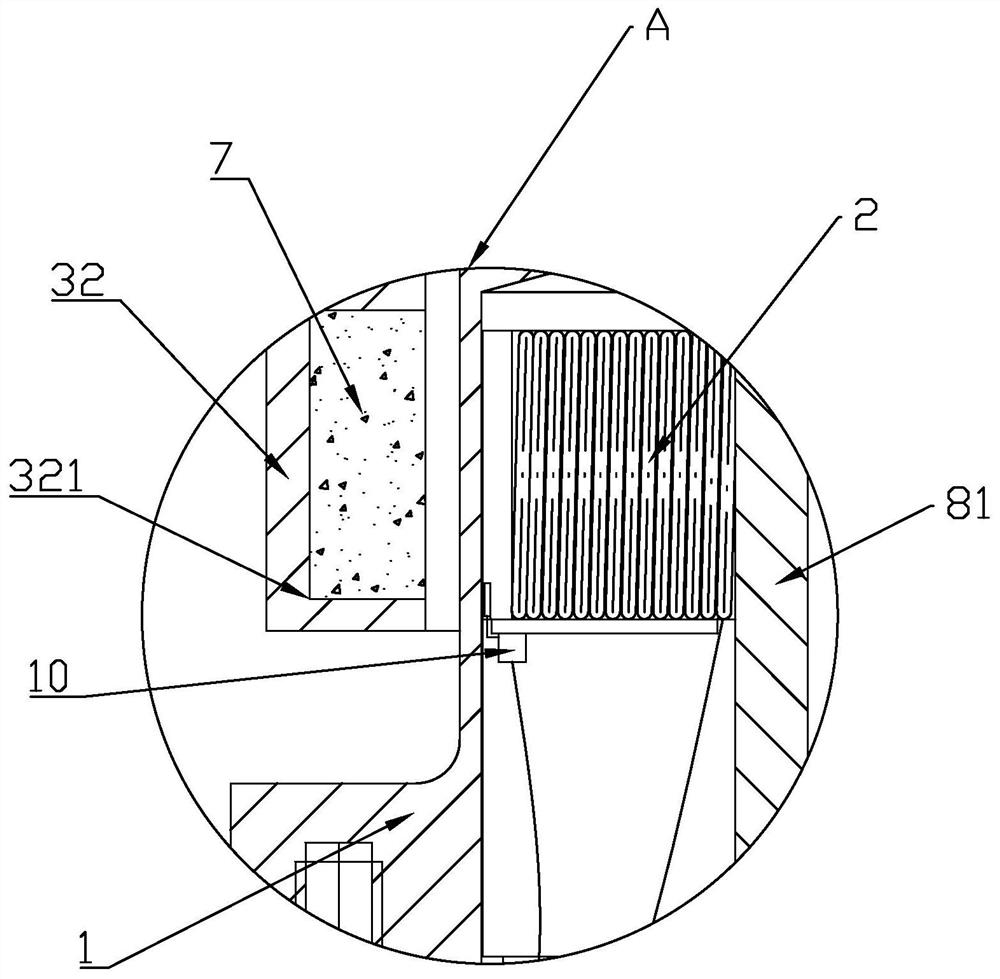

[0019] Such as Figure 1-Figure 2 As shown, a magnetic stirrer includes a spacer 1, a stator coil 2, a rotor 3 and a controller 4. The spacer 1 is welded to the container to be stirred and fixed as a whole to ensure the seal without leakage. The stator coil 2 is installed on In the spacer 1, the controller 4 supplies power to the stator coil 2, and one end of the spacer 1 is fixed or integrally provided with a support shaft 5, and the rotor 3 is rotated on the support shaft 5 through a silicon carbide bearing 6, and the rotor 3 is fixed or integrally provided There are paddles 31, and the rotor 3 is provided with an annular magnet 7 corresponding to the stator coil 2, and the stator coil 2 can drive the rotor 3 to rotate to realize stirring by the paddles 31. The controller 4 mainly plays the role of power supply and switch control, and the controller 4 is a conventional technical means in the field, so it will not be specifically introduced in this article.

[0020] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com