A medical disinfectant barrel sealing equipment

A technology for medical use and liquid barrels, applied in packaging and other fields, can solve the problems of low work efficiency and manpower consumption of manual operation, and achieve the effects of saving manpower, improving work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] first implementation

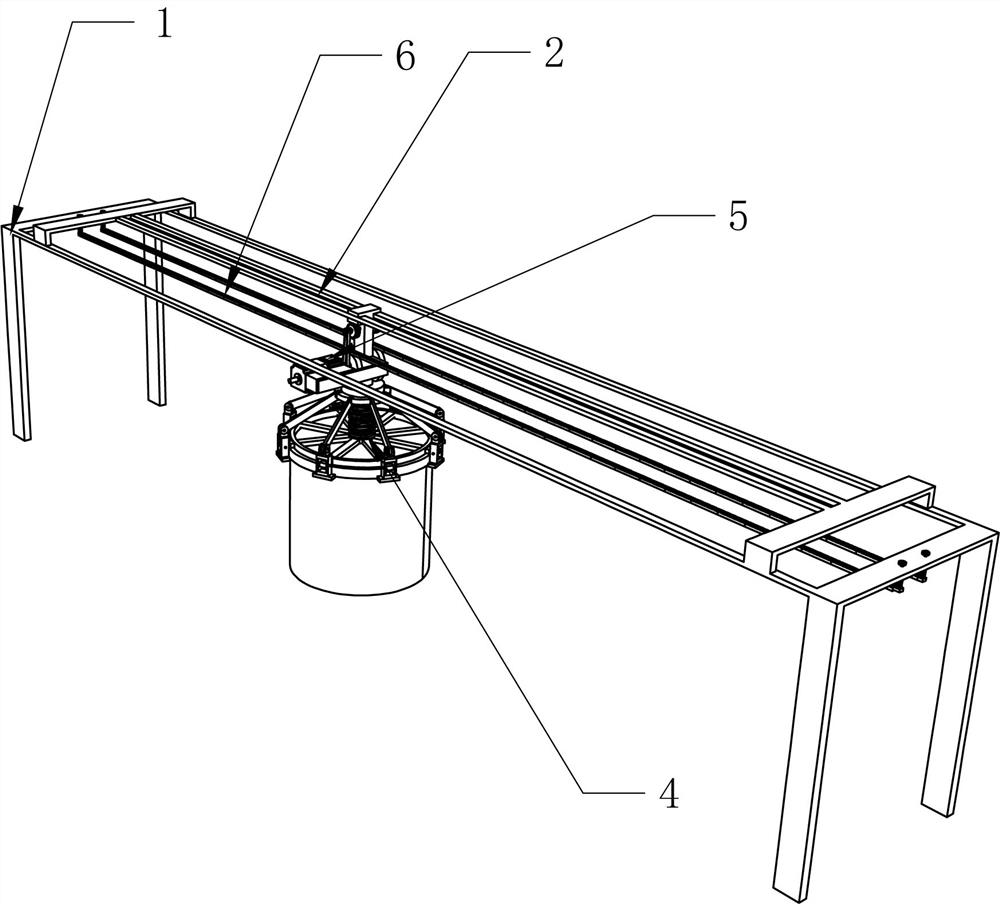

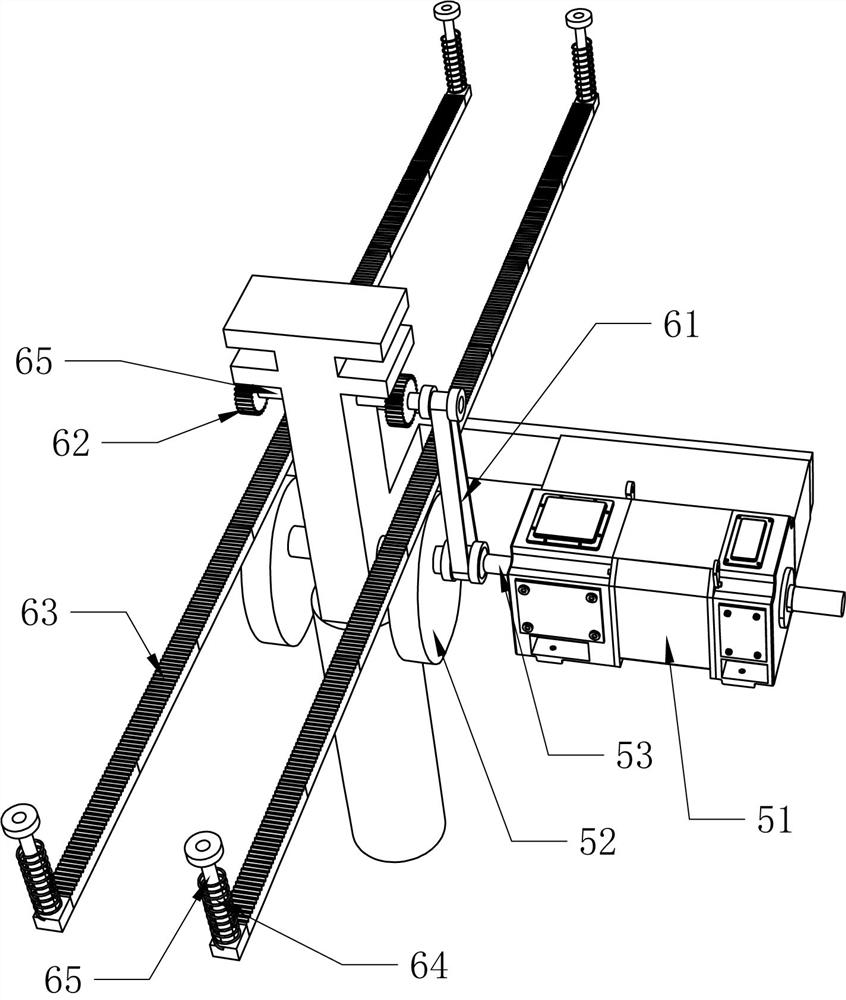

[0023] A medical disinfectant barrel capping equipment, such as Figure 1-3 As shown, it includes a frame 1, a sliding frame 2 and a pressing assembly 4. The sliding frame 2 is connected to the top of the frame 1, and the pressing assembly 4 is slidably connected to the sliding frame 2.

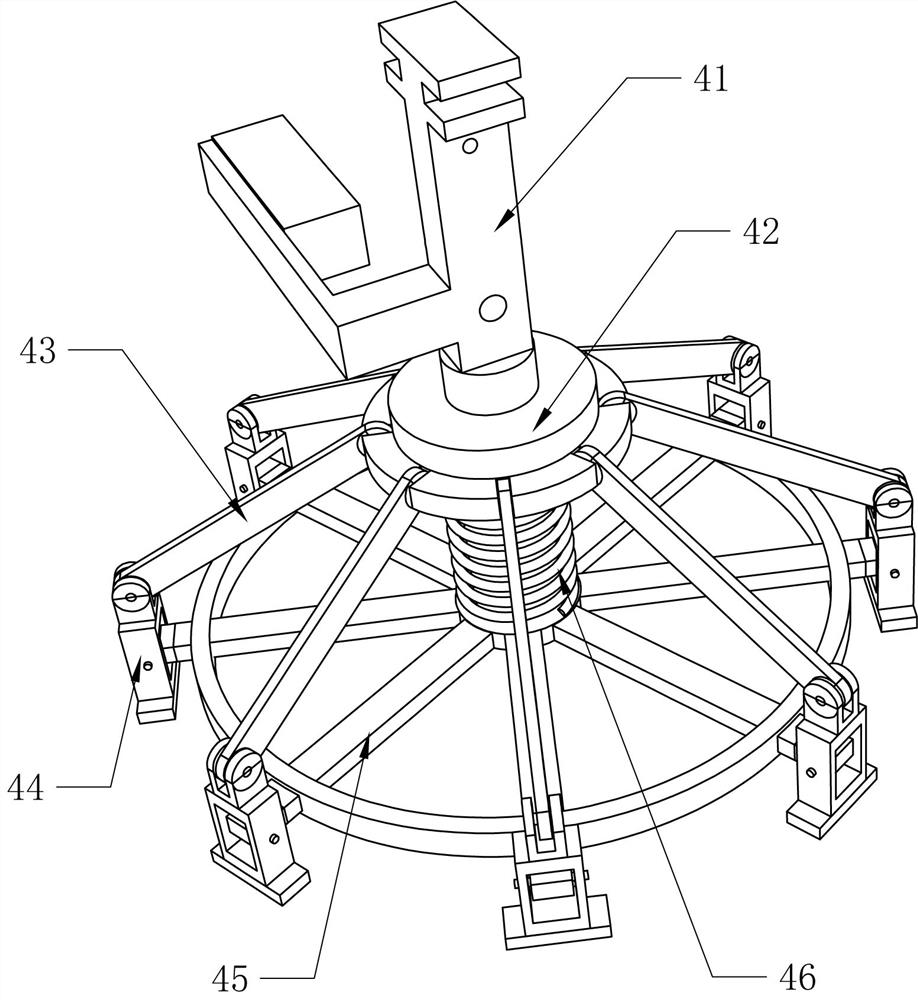

[0024] The compression assembly 4 includes a support 41, a lower pressing block 42, a pressing rod 43, a sealing rod 44, a fixed rod 45 and a first return spring 46. The sliding frame 2 is slidably connected to a support 41, and the lower part of the support 41 is slidably connected to a The lower pressing block 42 is hingedly connected with multiple pressing rods 43 evenly spaced along the circumferential direction, the ends of the pressing rods 43 are hingedly connected with sealing rods 44, and the insides of the plurality of sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com