Preparation method of charge transport layer and light emitting diode

A charge transport layer, light-emitting diode technology, applied in circuits, electrical components, electro-solid devices, etc., can solve the problems of low exciton mobility and dissociation, and achieve high exciton mobility, high efficiency and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

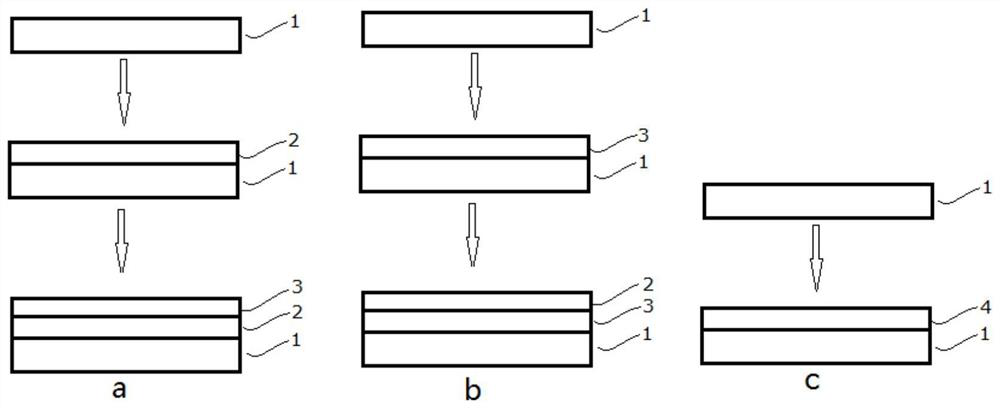

[0021] In one aspect, embodiments of the present invention provide a method for preparing a charge transport layer. The preparation method of the charge transport layer includes using a first solution containing a functional material to form a first film layer and using a second solution containing a charge transport material to form a second film layer, and making the first film layer and the second film layer The film layers are adjacent to each other, and then remove the functional material to obtain the charge transport layer; or use the mixed solution of the first solution and the second solution to form a mixed film layer, and then remove the functional material to obtain the charge transport layer. Therefore, in the embodiment, the preparation method of the charge transport layer includes at least the following three preparation methods of the charge transport layer:

[0022] The first preparation method of the charge transport layer:

[0023] The process flow of the f...

Embodiment 1

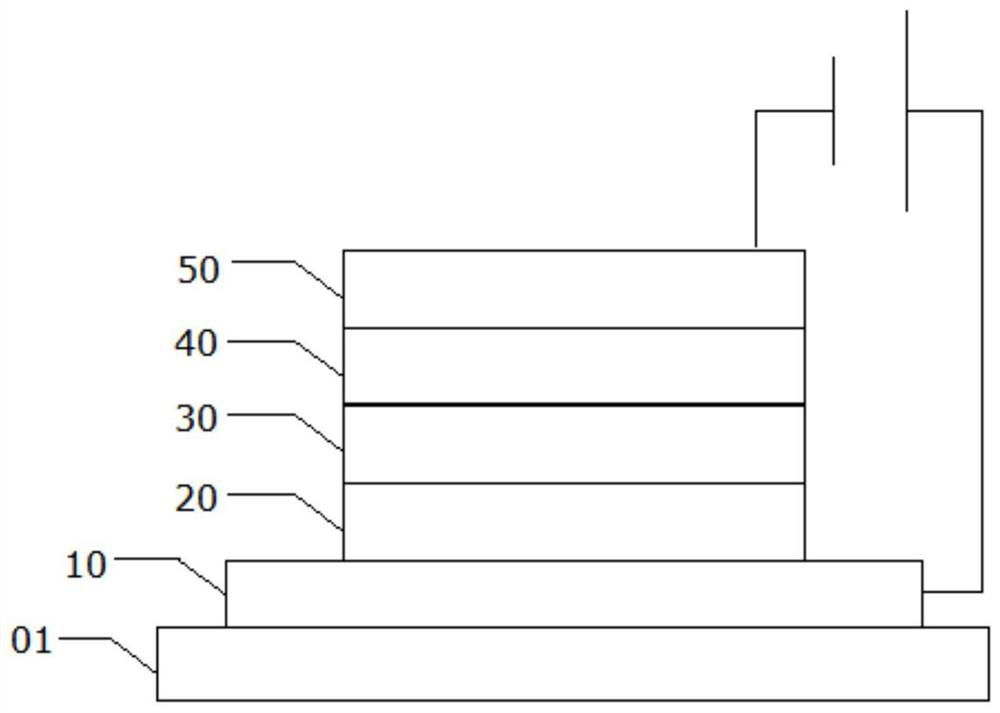

[0062] This embodiment provides a QLED light-emitting diode and a manufacturing method thereof.

[0063] The structure of the QLED light-emitting diode is as follows figure 2 The positive quantum dot light-emitting diode shown has the structure of ITO / PEDOT:PSS(30nm)hole transport layer(30nm) / CdSe / ZnS(40nm) / electron transport layer(40nm) / Ag(120nm). Among them, " / " expresses the connection relationship of the layer structure of the layered bonding.

[0064] The preparation method of the QLED of the present embodiment includes the following steps:

[0065] S1: providing a substrate on which a bottom electrode (anode) is formed;

[0066] S2: sequentially depositing an organic hole injection layer, an organic hole transport layer, and a quantum dot light-emitting layer on the bottom electrode;

[0067] S3: First deposit a zinc oxide-ethanol solution on the surface of the quantum dot light-emitting layer to form a zinc oxide electron transport wet film layer, which is also the ...

Embodiment 2

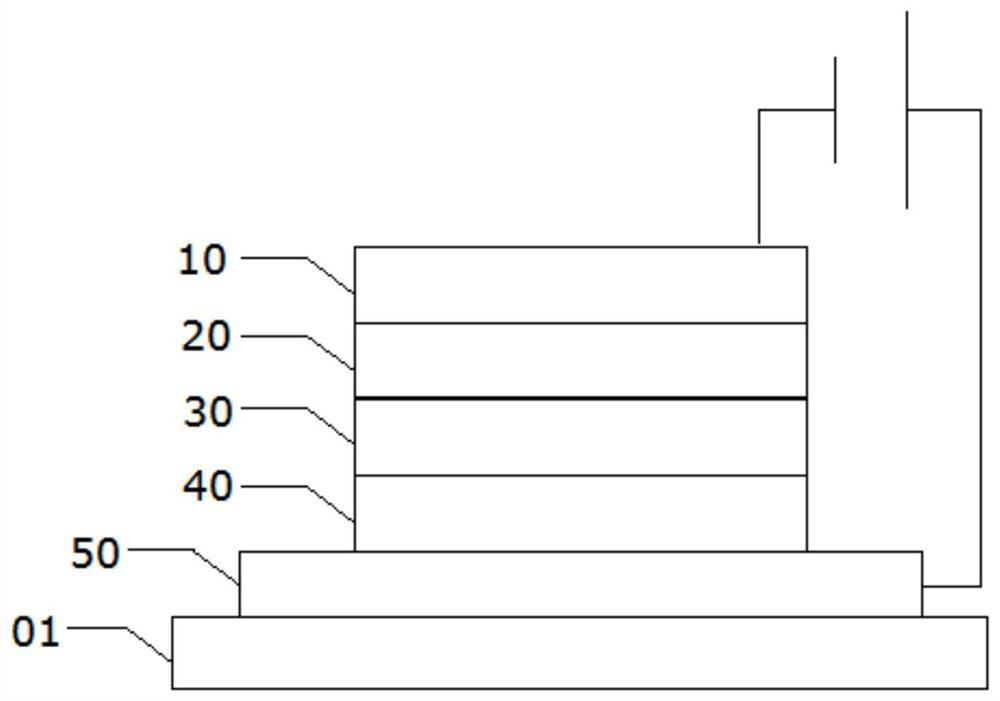

[0070] This embodiment provides a QLED light-emitting diode and a manufacturing method thereof.

[0071] The structure of the QLED light-emitting diode is as follows figure 2 The positive quantum dot light-emitting diode shown has the same structure as that of Example 1.

[0072] The preparation method of the QLED of the present embodiment includes the following steps:

[0073] S1: providing a substrate on which a bottom electrode (anode) is formed;

[0074] S2: sequentially depositing an organic hole injection layer, an organic hole transport layer, and a quantum dot light-emitting layer on the bottom electrode;

[0075] S3: deposit triethylamine-acetone solution on the surface of the quantum dot light-emitting layer first to form a first film layer of triethylamine; then deposit zinc oxide-ethanol solution on the surface of the first film layer to form a zinc oxide electron transport wet film layer to form a zinc oxide-triethylamine composite wet film layer, and then hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com