A device for decomposing and recycling dry batteries based on the principle of reciprocating motion

A technology of reciprocating motion and recycling device, which is applied in the field of dry battery decomposition and recycling device, to achieve the effects of preventing waste, facilitating subsequent processing, and reducing the subsequent processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

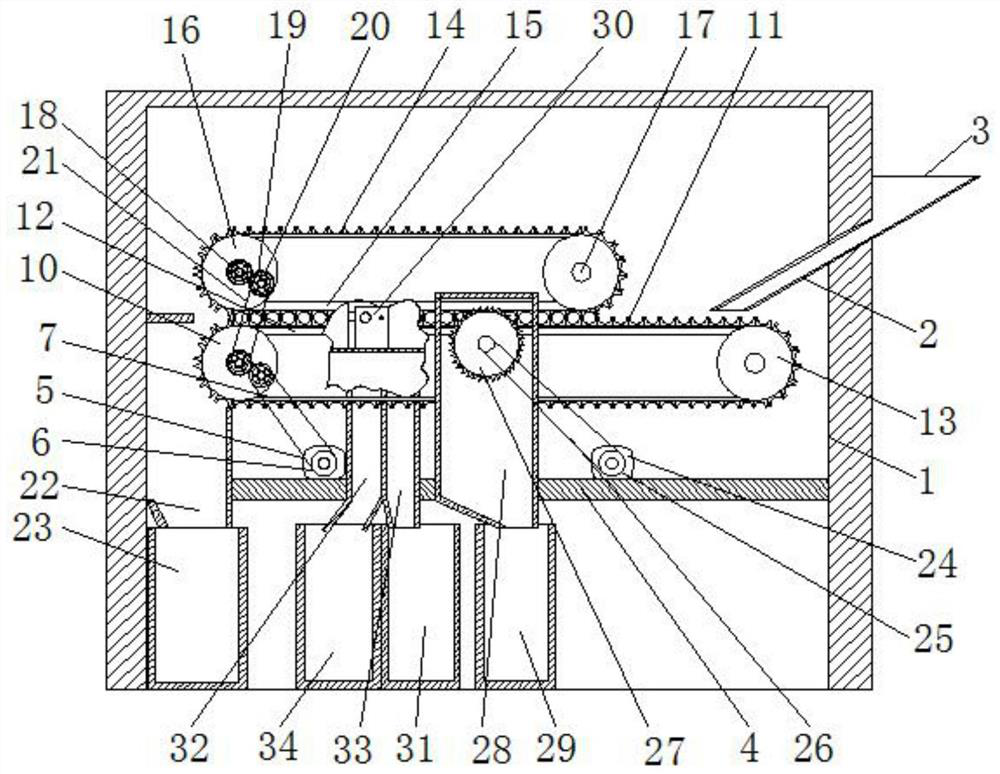

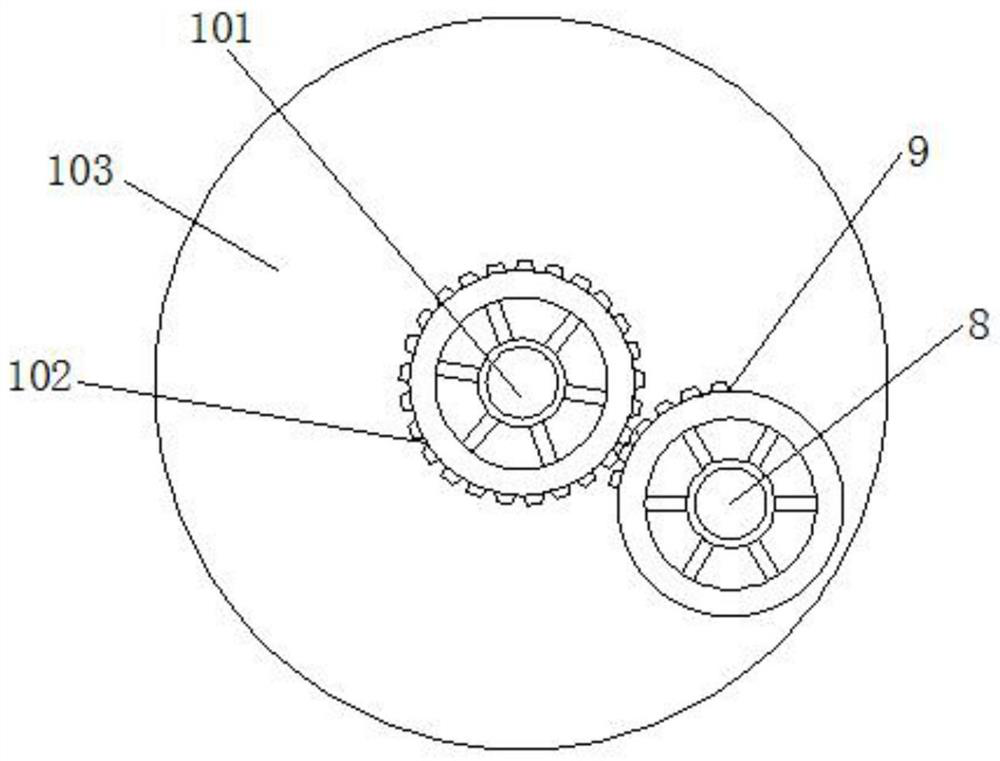

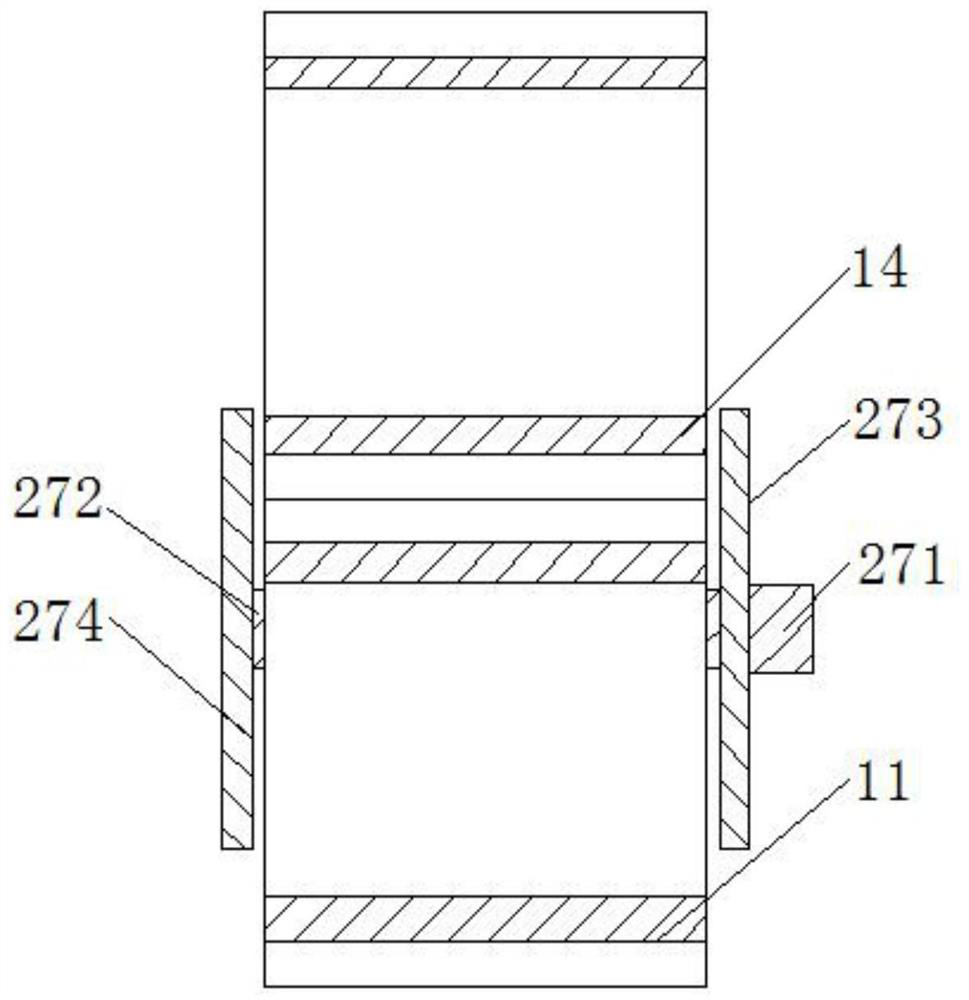

[0042]SeeFigure 1-9A dry battery decomposition recovery device based on the reciprocating principle, including the housing 1, the outer fixation of the housing 1, and the top of the material 2 is fixedly connected to the feed port 3, and the internal fixed connection of the housing 1 is supported. The frame 4, the inside of the support frame 4 is fixedly connected to the motor one 5, and the external activity of the motor one 5 is connected to the transfer wheel one 6, and the external activity of the transfer wheel one 6 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com