Device for transporting and stacking prefabricated floor slab components and use method thereof

A component and floor slab technology, applied in the field of transport and stacking devices for prefabricated floor slab components, can solve problems such as loss, impact on perception, stress concentration, etc., and achieve the effects of strong applicability, large promotion value, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

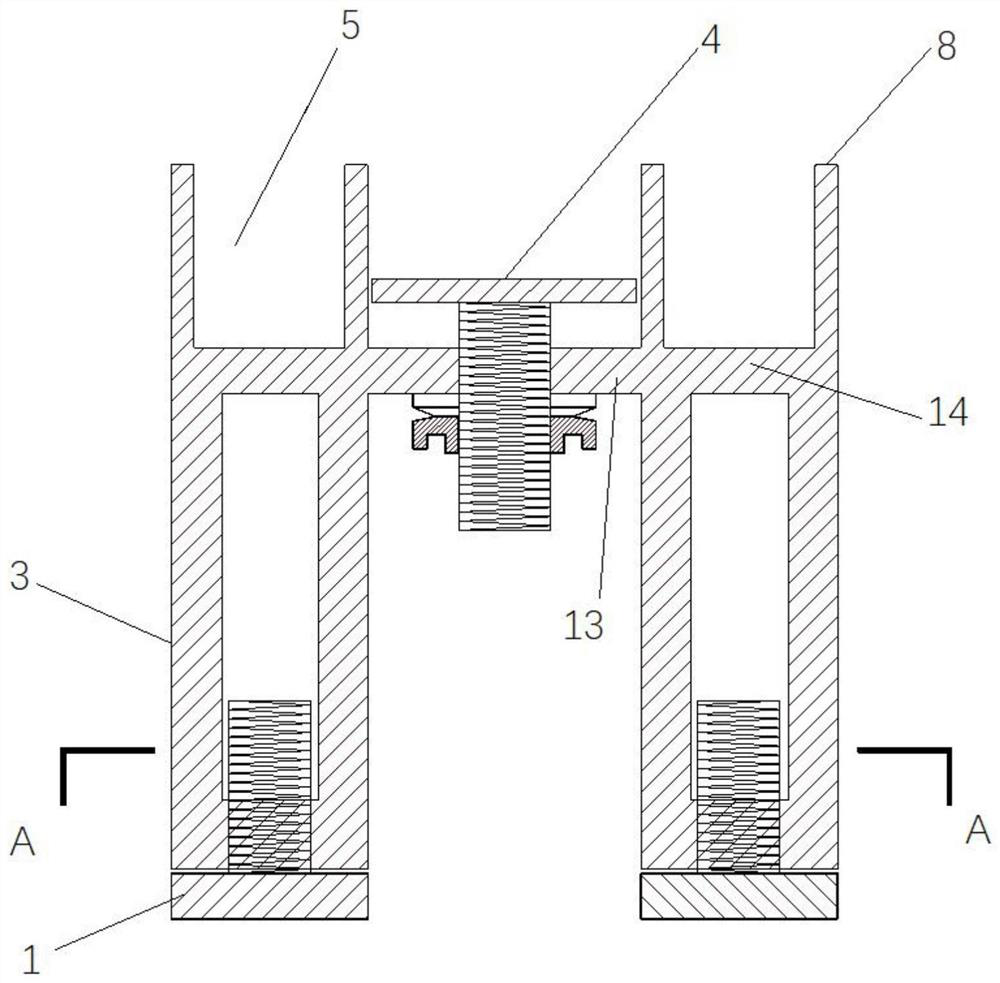

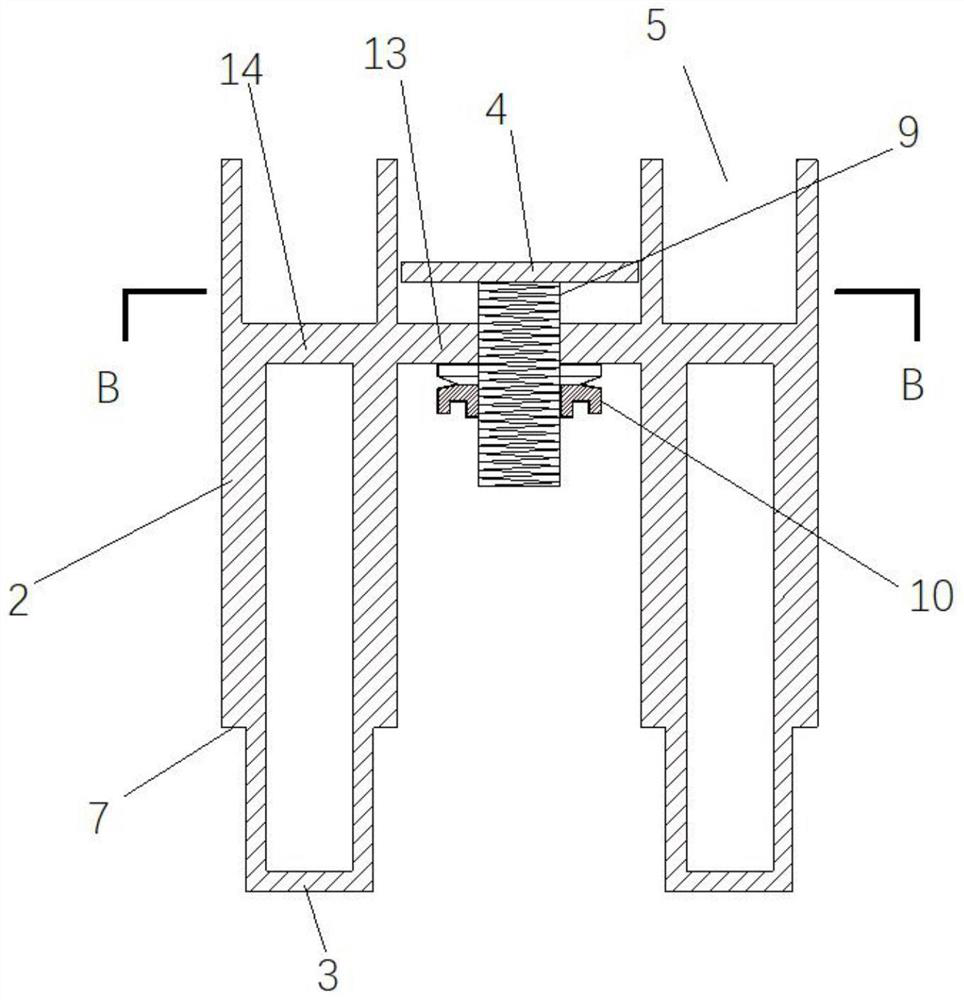

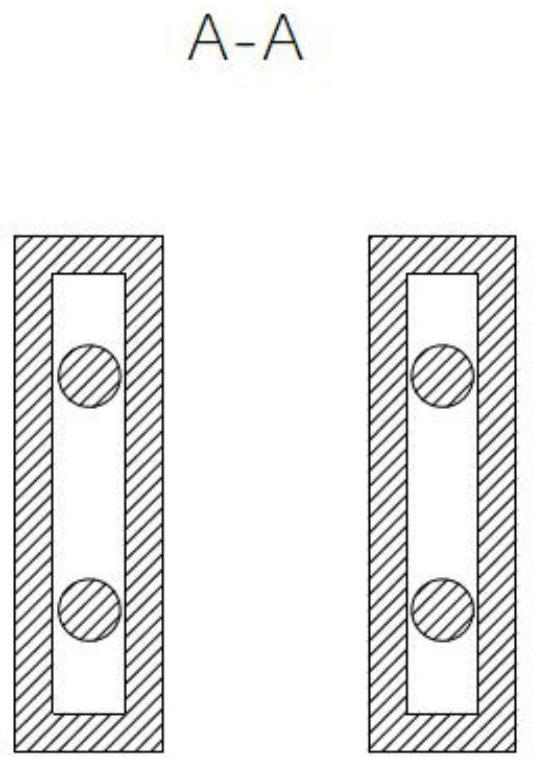

[0035] A device for transportation and stacking of prefabricated floor components, see Figure 1 to Figure 5 , including the base base 1 and the standard support 2, the left side and the right side of the base base 1 and the standard support 2 are respectively provided with feet 3, between the two feet 3 of the base base 1, and the two feet of the standard support 2 A liftable lifting plate 4 is arranged between the legs 3, and the two sides of the lifting plate 4 are respectively provided with card slots 5; the two legs 3 of the base base 1 are liftable structures; the base base 1 is located under the standard support 2 , the feet 3 of the standard support 2 are installed in the slot 5 of the foundation base 1 .

[0036] The device for transportation and stacking of prefabricated floor components in this embodiment has a height adjustment function through the combined structure of the foundation base 1 and the standard support 2, and can be applied to multiple thickness speci...

Embodiment 2

[0044] For the usage method of the prefabricated floor member transportation and stacking device of embodiment 1, see Figure 9 , including the following steps,

[0045] In the first step, when stacking the reinforced truss-concrete laminated slabs 12, the four foundation bases 1 are placed on the ground in two rows and two rows;

[0046] The second step is to place wooden cubes 11 on the lifting plates 4 of the two foundation bases 1 of each row or column;

[0047] The third step is to adjust the lifting bolts 6 on both sides of the base base 1 according to the thickness of the laminated board to adjust the height of the base base 1;

[0048] The fourth step is to stack a layer of reinforced truss concrete composite slab 12 on the wooden side 11 of the foundation base 1, and then adjust the lifting plate 4 of the foundation base 1;

[0049]The fifth step is to extend the feet 3 of the four standard supports 2 into the slots 5 of the four basic bases 1 respectively, and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com