Preparation method and failure analysis method of bare chip taken from flip chip

A bare chip, flip chip technology, used in semiconductor/solid-state device manufacturing, electrical components, semiconductor/solid-state device testing/measurement, etc., can solve problems such as chipping or cracking of bare chips, and achieve improved accuracy and excellent technical results. , the effect of improving the accuracy of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to solve the technical problem of chipping or cracks in the prior art when taking bare chips from flip chip chips, the present invention provides a preparation method for taking bare chips from flip chip chips.

[0034] A preferred embodiment of the method for preparing a flip-chip chip and a bare chip according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

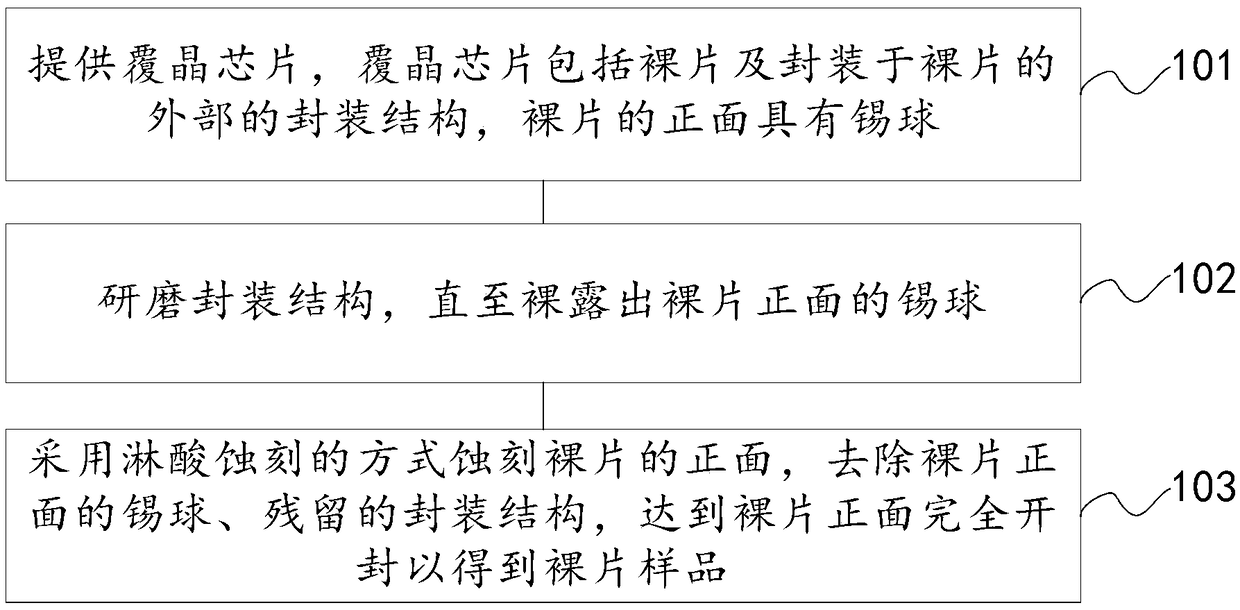

[0035] combine Figure 1 to Figure 6 As shown, the flip-chip chip provided by the present invention takes the preparation method of the bare chip, comprising:

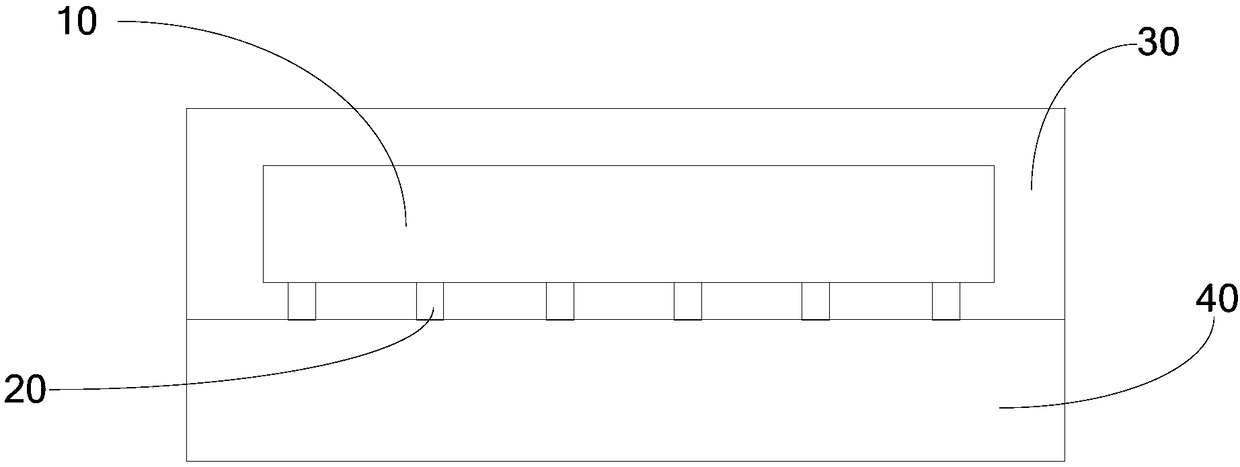

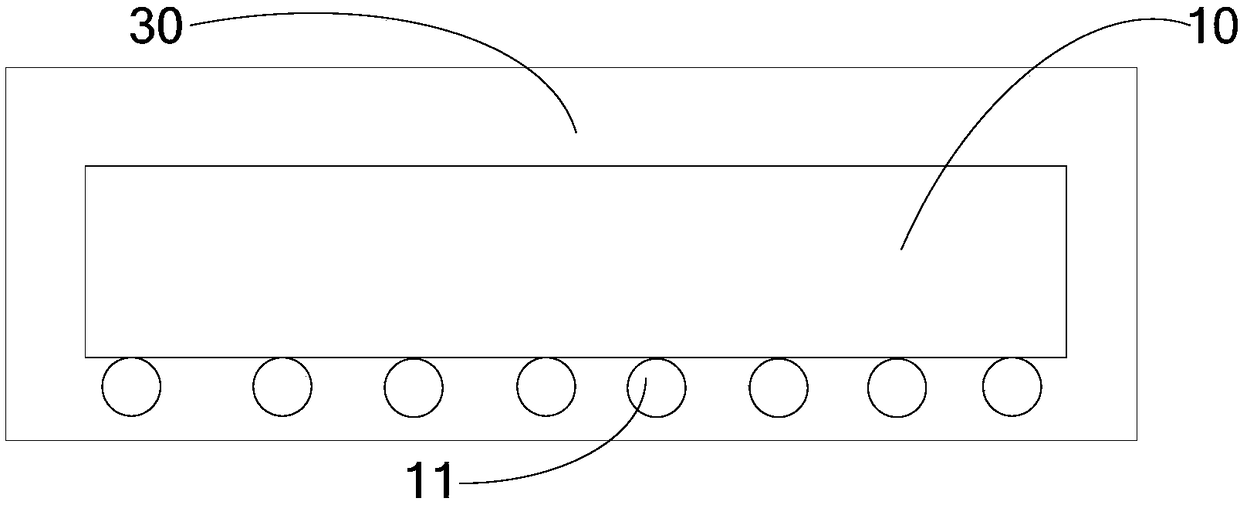

[0036] Step 101: providing a flip-chip chip, the flip-chip chip includes a bare chip 10 and a packaging structure packaged outside the bare chip 10, and the front side of the bare chip 10 has solder balls 11;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com