A kind of self-foamable aqueous polyurethane resin emulsion and preparation method thereof

A water-based polyurethane and resin emulsion technology, applied in the field of water-based polyurethane, can solve the problems of complicated production process, precipitation of finished synthetic leather, affecting product quality, etc., and achieve the effect of simplifying the feeding process, improving production efficiency and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

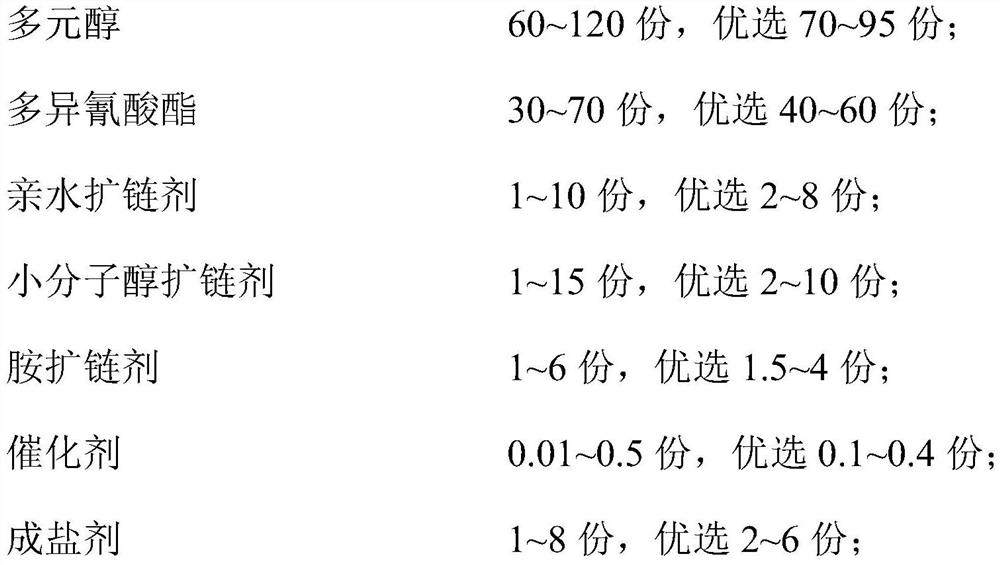

Method used

Image

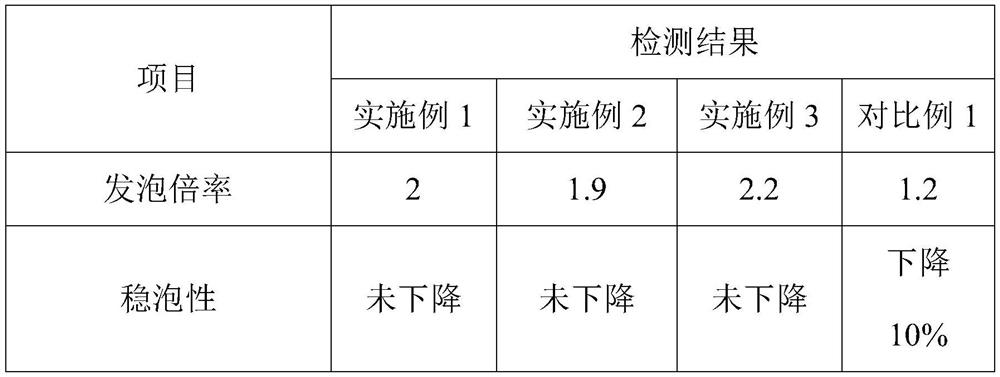

Examples

Embodiment 1

[0055] Dehydrate 100g of polytetrahydrofuran ether polyol (molecular weight: 2000) at 105°C for 1h, then cool down to 50°C, add 60g of dicyclohexylmethane diisocyanate, raise the temperature to 90°C and keep it warm for 3 hours, measure the NCO content, and reach the theoretical After the value is 9.40%, cool down to 50°C, then add 6g of dimethylolpropionic acid, 6g of ethylene glycol, and 9g of polyether-modified siloxane to react at 80°C for 2 hours, cool down to 50°C, and then add 0.2g of organic bismuth Coscat83 and 10ml acetone to adjust the viscosity, react at 70°C for 2.5h, then cool down to 0°C, add 4.3g of triethylamine for neutralization, after neutralization for 10min, add 367.5g of deionized water under high-speed shear at 1500rpm, and disperse After 7 minutes, 1.48 g of ethylenediamine was slowly added to react for 10 minutes. The final NCO value was 1.15%. The acetone and part of the water in the system were distilled off under reduced pressure to obtain an aqueou...

Embodiment 2

[0057]Dehydrate 50g of polytetrahydrofuran ether polyol (molecular weight: 1500) and 50g polypropylene oxide polyol (molecular weight: 2500) at 110°C for 1h, then cool down to 50°C, add 65g of isophorone diisocyanate, and heat up Heat the reaction at 90°C for 3 hours, measure the NCO content, and cool down to 50°C after reaching the theoretical value of 12.17%, then add 4g of dimethylol propionic acid, 10g of ethylene glycol, and 8g of polyether modified siloxane at 80°C React for 2 hours, cool down to 50°C, then add 0.2g of organic bismuth Coscat83 and 8ml of acetone to adjust the viscosity, react at 70°C for 2.5h, then cool down to 0°C, add 1.13g of sodium hydroxide for neutralization, after 10 minutes of neutralization , add 379.7g of deionized water under high-speed shear at 1500rpm, disperse for 5min, then slowly add 3.82g of hexamethylenediamine, react for 20min, the final NCO value is 1.49%, remove the acetone and part of the water in the system by distillation under red...

Embodiment 3

[0059] Dehydrate 85g of polypropylene oxide polyol (molecular weight: 2000) at 100°C for 2h, then cool down to 50°C, add 50g of dicyclohexylmethane diisocyanate, raise the temperature to 85°C and keep it warm for 3.5 hours to measure the NCO content. Cool down to 50°C after the theoretical value is 9.23%, then add 2.5g dimethylol butyric acid, 7g 1,4-butanediol, 1g 2,2,3,3,3-pentafluoro-1-propanol at 80 React at ℃ for 2 hours, cool down to 50℃, then add 0.25g organic bismuth Coscat83 and 4ml acetone to adjust the viscosity, react at 75℃ for 2h, then cool down to 0℃, add 1.79g of triethylamine for neutralization, and neutralize for 10min Finally, add 299.8g of deionized water under high-speed shear at 1500rpm, disperse for 10min, then slowly add 2.19g of ethylenediamine, react for 15min, the final NCO value is 1.985%, and remove acetone and part of the water in the system by distillation under reduced pressure, namely An aqueous polyurethane resin emulsion 3 with a solid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com