Precast pile construction method capable of dissipating foundation soil pore water pressure and preventing pile body from floating

A technology of pore water pressure and construction method, applied in the direction of soil protection, foundation structure engineering, sheet pile wall, etc., can solve the problems of increasing equipment shift fee, increasing construction period, and high cost, and achieves floating and horizontal displacement control, increasing The effect of pile side friction resistance and avoiding common quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

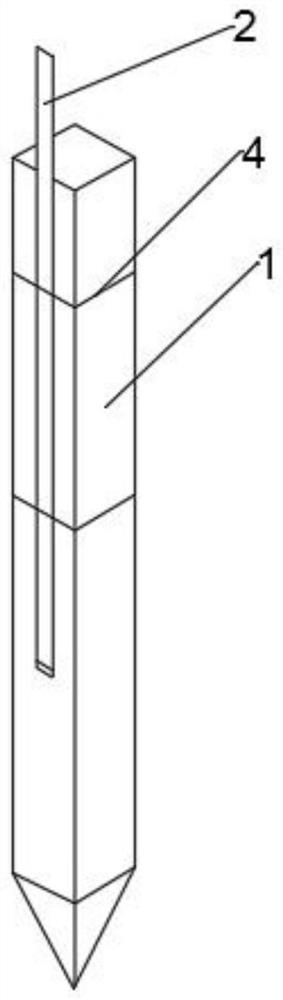

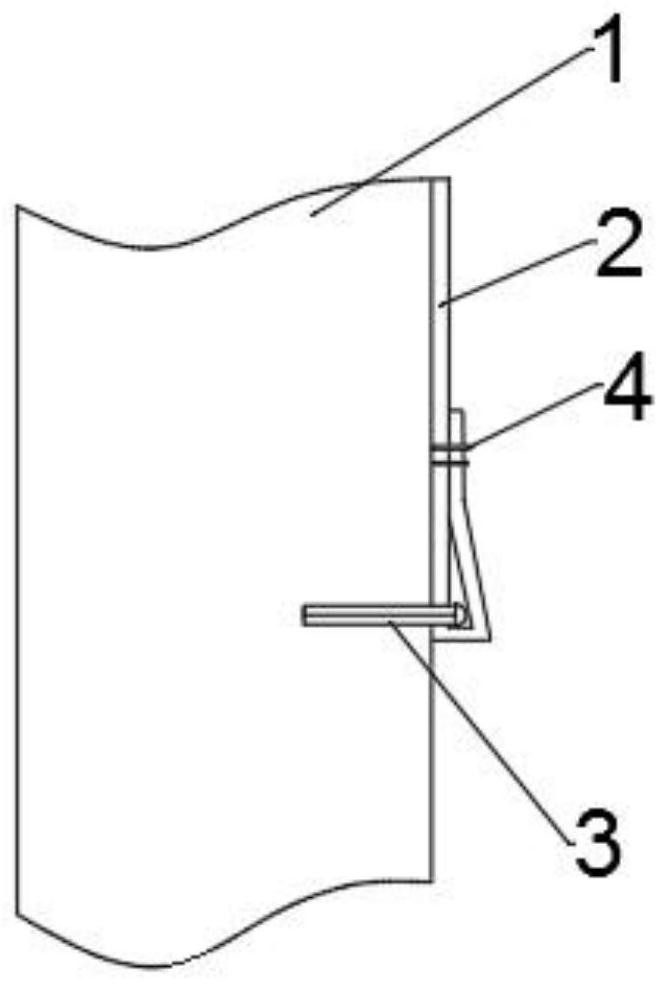

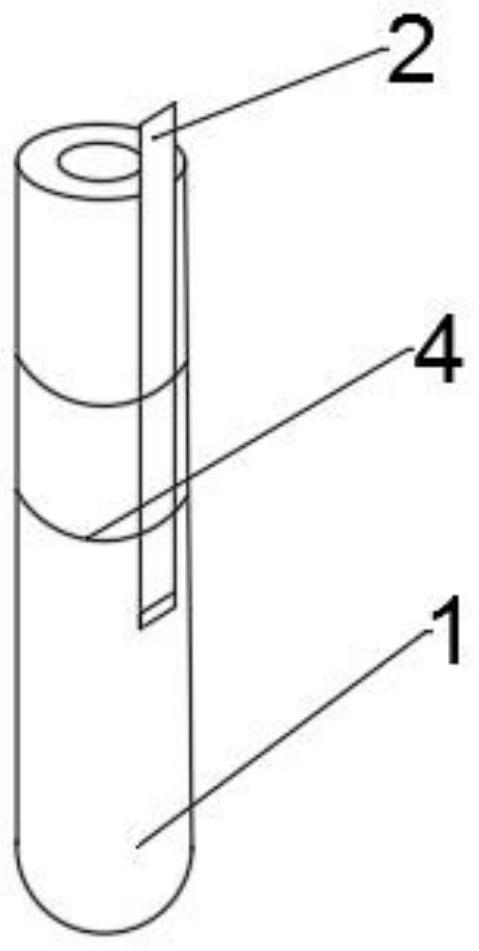

[0025] Specific examples figure 1 As shown, the qualified prefabricated pile 1 made by the factory is transported to the construction site, and the fixed position of the drainage board 2 is determined according to the position and thickness of the soft ground layer, and the required length of the drainage board is calculated so that it is 0.5m above the ground; Drill a hole at the bottom of the pile 1 to fix the drainage board 2, make a U-shaped steel clip 3 fixing device, hang the drainage board 2 evenly on the 4 sides of the prefabricated pile 1 body, roll up the bottom of the drainage board 2 by 15cm and use U-shaped steel clamp 3 and three lead wires securely fix the bottom of the drainage board 2 on the body of the prefabricated pile 1; along the body of the prefabricated pile at intervals of 1.5m, fix the drainage board 2 on the body of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com