Tower crane foundation embedded positioning auxiliary tool and tower crane foundation embedded plate positioning method

A technology for tower crane foundation and positioning assistance, which is applied in infrastructure engineering, construction, etc., can solve problems such as complex installation, low construction efficiency, and inaccurate positioning, and achieve the effect of improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

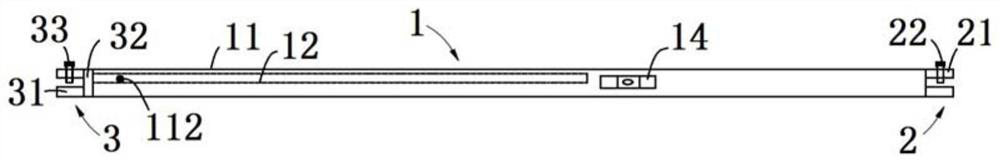

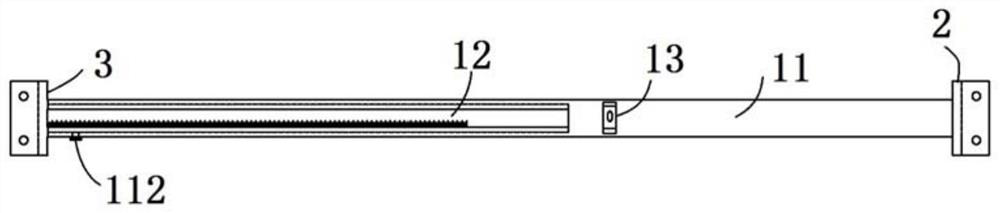

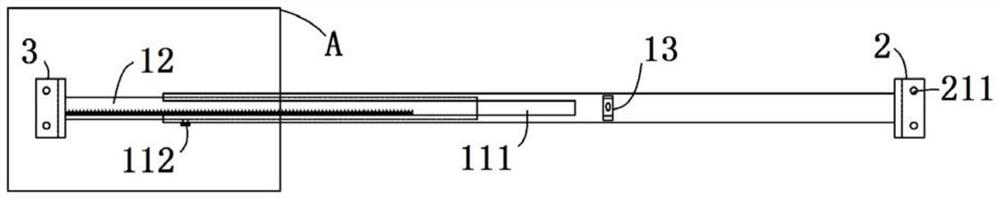

[0032] In order to facilitate the understanding of the present invention, the following description is given in conjunction with the drawings and embodiments.

[0033] See figure 1 and Figure 5 As shown, the present invention provides a tower crane foundation embedded positioning auxiliary tool, including: a telescopic positioning rod 1, a first anchoring slot 2 and a second anchoring slot 3 provided at both ends of the telescopic positioning rod 1, and a level bubble, The first anchoring slot 2 and the second anchoring slot 3 are used to connect and fix the embedded plate 3 of the tower crane foundation, and the level bubble is used to level the telescopic positioning rod 1 and then to the tower crane foundation connected to the telescopic positioning rod 1 The embedded board 4 is leveled. The present invention can adjust the length of the telescopic positioning rod 1 according to the distance between two adjacent tower crane foundation embedded plates 4, so that the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com